Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Unveiling the Magic: Boost Performance with Advanced Bearing Coating

Introduction

In the dynamic landscape of industrial machinery, the efficacy of bearings stands as a linchpin for seamless operations across diverse sectors. A transformative force in this realm is the introduction of Advanced Bearing Coating. This section serves as an entry point into a comprehensive exploration, dissecting the multifaceted aspects of this pioneering technology. We will unravel the intricate components underpinning advanced coating, examine the tangible advantages it bestows, scrutinize its applications across industries, and prognosticate the trajectory it is likely to take in the future. As we navigate through this detailed analysis, a profound understanding of how Advanced Bearing Coating reshapes the dynamics of machinery performance will unfold.

Basics of Bearing Coating

Overview of Traditional Bearing Coating

Traditional bearing coatings aim to enhance the performance and durability of bearings by mitigating factors like friction and wear. Commonly used coatings include zinc, cadmium, nickel, and chromium plating. Zinc coatings offer corrosion resistance, while cadmium provides excellent lubricity. Nickel and chromium coatings offer improved hardness and wear resistance. Additionally, thin films of materials like molybdenum disulfide or graphite may be applied for lubrication purposes. These coatings act as protective barriers, reducing friction between moving parts and preventing metal-to-metal contact. The choice of coating depends on the specific requirements of the application, considering factors such as load, speed, temperature, and environmental conditions. While traditional coatings have proven effective, advancements like NoWear coatings aim to further enhance bearing performance in demanding scenarios.

Evolution towards Advanced Coating Technologies

The evolution of traditional bearing coatings to advanced technologies has been driven by the need for improved performance, longevity, and efficiency in various industries. Initially, coatings like zinc, cadmium, nickel, and chromium plating were common for corrosion resistance and enhanced wear characteristics. As demands increased, developments led to the integration of advanced materials such as ceramics, polymers, and composites in coatings. These materials offer superior hardness, reduced friction, and increased resistance to extreme conditions. Furthermore, nanotechnology has played a role in creating nano-composite coatings, providing even greater strength and durability. Specialized coatings like DLC (Diamond-Like Carbon) and NoWear coatings focus on minimizing friction and wear, significantly extending bearing life. The shift towards advanced coating technologies represents a continuous effort to meet the evolving demands of modern industries for high-performance and reliability.

Key Components of Advanced Bearing Coating

Nanotechnology in Bearing Coatings

Nanotechnology has revolutionized bearing coatings by introducing nanoscale materials to enhance performance. In bearing applications, nanoparticles such as nano-diamonds, graphene, or nanocomposites are integrated into coatings to improve hardness, reduce friction, and enhance wear resistance. These nanoparticles provide a smoother and more uniform surface, reducing the risk of damage and extending the bearing’s lifespan. Additionally, nanotechnology allows for precise engineering of coatings, tailoring properties to specific requirements. Nanocoatings exhibit superior strength, resilience, and corrosion resistance, making them well-suited for demanding industrial environments. The application of nanotechnology in bearing coatings represents a significant advancement, contributing to increased efficiency, reduced maintenance, and improved overall performance in various mechanical systems.

Polymer-based Coatings

Polymer-based coatings in bearings offer a versatile solution for improving lubrication, enhancing elasticity, and boosting wear resistance. These coatings are often formulated from synthetic polymers or polymer composites, exhibiting unique properties that contribute to the efficient functioning of bearings. One notable advantage is their ability to provide effective dry lubrication, reducing friction between moving components without relying on traditional liquid lubricants. The molecular structure of polymers imparts enhanced elasticity, enabling them to absorb shocks and vibrations during operation, leading to smoother performance. Furthermore, these coatings create a protective barrier, guarding bearing surfaces against abrasive particles and corrosive elements, thus improving wear resistance. The adaptability of polymer-based coatings allows for tailoring their properties to specific application needs, making them valuable across diverse industries, including automotive, aerospace, and industrial machinery. In summary, polymer-based coatings play a pivotal role in extending bearing life, minimizing maintenance requirements, and optimizing overall operational efficiency.

Advantages of Advanced Coating

Enhanced Wear Resistance: Advanced bearing coatings, such as those utilizing nanotechnology or specialized materials like DLC (Diamond-Like Carbon), offer superior wear resistance. This results in prolonged bearing life and reduced need for frequent replacements.

Reduced Friction: Many advanced coatings are designed to minimize friction between bearing components. This not only increases efficiency but also contributes to energy savings in various applications.

Improved Lubrication: Advanced coatings often provide effective dry lubrication or work synergistically with lubricants. This ensures better lubrication under various operating conditions, reducing the risk of wear and tear.

Corrosion Protection: Coatings engineered with advanced materials offer enhanced corrosion resistance, making bearings more durable in harsh environments and extending their service life.

Increased Operational Efficiency: The combination of reduced friction, enhanced wear resistance, and improved lubrication leads to overall increased operational efficiency. This is particularly valuable in industries where machinery performance is critical for productivity and cost-effectiveness.

Heat Dissipation Properties: Advanced coatings dissipate heat efficiently, enabling bearings to perform optimally even in high-temperature environments.

Applications Across Industries

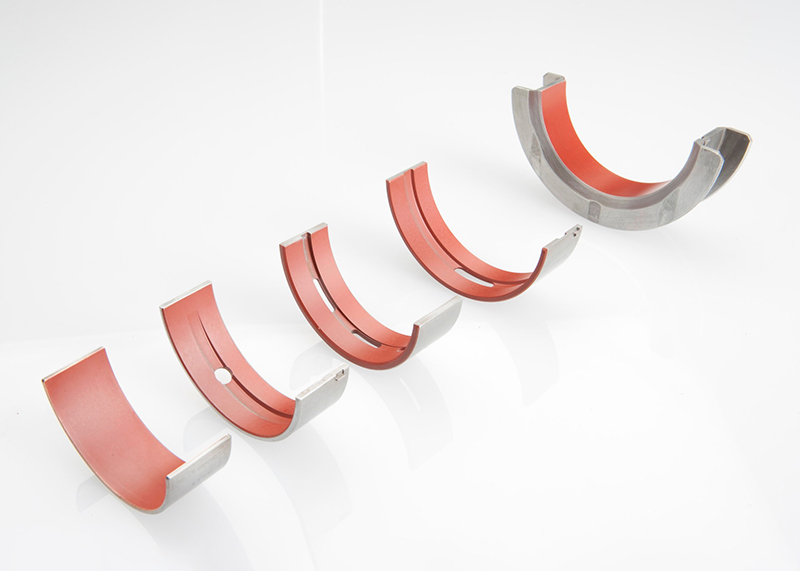

Automotive Industry: Advanced bearing coatings find applications in automotive components, such as engine bearings, transmission systems, and wheel hubs. These coatings enhance wear resistance, reduce friction, and contribute to increased fuel efficiency.

Aerospace: Bearings in aircraft and spacecraft benefit from advanced coatings to improve performance, reduce weight, and withstand the demanding conditions of high altitudes and variable temperatures.

Industrial Machinery: Advanced coatings are used in various industrial machinery, including pumps, compressors, and manufacturing equipment. They enhance the reliability and efficiency of these machines in diverse manufacturing processes.

Renewable Energy: Bearings in wind turbines and solar tracking systems utilize advanced coatings to withstand the challenging environmental conditions, such as exposure to wind, sand, and temperature variations, contributing to the reliability and longevity of these systems.

Choosing the Right Coating for Your Bearings

Factors Influencing Coating Selection

Operating Environment: The specific conditions in which the bearing will operate, such as temperature, humidity, and exposure to chemicals or corrosive substances, significantly influence coating selection.

Load and Speed Requirements: The load capacity and speed at which the bearing will operate are critical factors. Coatings must be chosen to withstand the mechanical stresses and friction associated with these conditions.

Application Type: The intended use of the bearing, whether in automotive, aerospace, industrial machinery, or other sectors, influences the choice of coating. Different applications may have specific requirements for wear resistance, friction reduction, or corrosion protection.

Material Compatibility: The compatibility of the coating material with the base material of the bearing is crucial. The coating should bond effectively with the substrate material to ensure durability and performance.

Cost Considerations: The economic aspect plays a role in coating selection. Balancing the cost of the coating with the potential benefits it provides, such as extended lifespan and reduced maintenance, is essential.

Maintenance Requirements: The level of maintenance the application can afford may impact coating selection. Coatings that require minimal maintenance or are self-lubricating can be advantageous in certain scenarios.

Challenges and Innovations

Addressing Common Misconceptions about Bearing Coatings

Misconceptions about bearing coatings often stem from exaggerated claims of universal durability and maintenance-free performance. One common fallacy is the belief that all coatings offer identical performance, neglecting the crucial role of application-specific requirements. The reality is that coating effectiveness hinges on factors like operating conditions, loads, and the unique demands of each application. Another misconception assumes that advanced coatings render bearings completely maintenance-free, ignoring the significance of proper installation, regular monitoring, and occasional maintenance. Dispelling these misconceptions necessitates educating users about the nuanced nature of bearing coatings. It’s imperative to stress the importance of selecting coatings based on specific application needs and to clarify that while advanced coatings enhance performance, they do not eliminate the need for proper care and attention. This approach fosters realistic expectations, showcasing the true durability and resiliency of advanced bearing coatings.

Overcoming Preconceptions in the Industry

Promoting widespread acceptance of advanced coating technologies involves innovative solutions to industry challenges. Our approach centers on comprehensive educational initiatives designed to address prevailing misconceptions and overcome obstacles. Through tailored content dissemination, we highlight the versatility and effectiveness of advanced coatings across diverse applications. Collaborative efforts with industry stakeholders play a vital role in knowledge exchange and the promotion of best practices. By prioritizing user feedback and continuously refining our strategies, we ensure adaptability to evolving needs. Transparency and ongoing communication build trust within the industry, encouraging broader adoption of advanced coating technologies. Through these initiatives, we actively shape a more informed and receptive industry landscape, emphasizing the reliability and benefits of cutting-edge coating solutions.

Maintenance and Care Tips

Best Practices for Prolonging Coating Lifespan

Proper Lubrication: Implementing a robust lubrication maintenance program is crucial for extending bearing coating life. Adequate lubrication reduces friction, minimizes wear, and enhances the overall performance of the coating.

Regular Monitoring and Maintenance: Conduct routine inspections to identify any signs of wear, damage, or degradation of the coating. Timely maintenance, such as cleaning and reapplication of coatings when needed, helps prevent further deterioration.

Correct Installation: Ensure proper installation of bearings and coatings, following manufacturer guidelines and specifications. Incorrect installation can lead to uneven loading, misalignment, and premature coating failure.

Application-Specific Coating Selection: Choose coatings based on the specific demands of the application. Consider factors such as operating conditions, loads, and environmental influences to ensure the selected coating is well-suited for the intended purpose.

Temperature Control: Maintain optimal operating temperatures for the bearing and coating. Excessive heat can accelerate wear and compromise the effectiveness of the coating, so monitoring and controlling temperature conditions are essential for longevity.

Troubleshooting Common Coating Issues

Visible Wear or Flaking: If you observe visible signs of wear or coating flaking, it may indicate excessive friction or abrasive contaminants. Inspect the operating conditions and lubrication quality, ensuring that the system is properly aligned and that the bearing is not overloaded.

Corrosion and Rust: Corrosion can compromise the coating’s integrity. Check for signs of corrosion and rust, particularly in challenging environments. Address issues related to moisture, humidity, or exposure to corrosive substances. Consider using coatings with enhanced corrosion resistance.

Irregular Noises or Vibrations: Unusual noises or vibrations may indicate issues with the bearing coating. Conduct a thorough inspection for misalignment, inadequate lubrication, or the presence of foreign particles. Adjustments or replacements may be necessary to restore optimal performance.

Inconsistent Performance: If the bearing coating exhibits inconsistent performance, review the operating conditions, load distribution, and environmental factors. Ensure that the chosen coating aligns with application-specific requirements and consider consulting with experts to identify and address potential root causes.

Conclusion

In conclusion, Advanced Bearing Coating represents a transformative leap in industrial machinery, optimizing performance across diverse sectors. From the evolution of traditional coatings to incorporating nanotechnology and polymers, these advancements offer enhanced wear resistance, reduced friction, and improved operational efficiency. Strategic coating selection, addressing misconceptions, and diligent maintenance are crucial. As industries embrace these innovations, a future where machinery operates seamlessly with extended lifespans becomes increasingly tangible, emphasizing the pivotal role of Advanced Bearing Coating in shaping the dynamics of modern machinery performance.

References

1.”Ceramic-Coated Insulated Ball Bearings HDY2” from NSK;

2. “How coatings can maximize rolling bearing performance” from Processing Magazine;

3. “NoWear coated bearings” from SKF Bearings.