Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Comparative Analysis: Toroidal Roller Bearings vs. Other Roller Bearing Types

Introduction

Overview of Roller Bearing Types

Roller bearings come in various types, each designed to meet specific needs and applications. Toroidal roller bearings are unique due to their toroidal shape, offering exceptional flexibility and self-aligning capabilities. These bearings can handle both radial and axial loads, making them ideal for applications where shaft misalignment or deflection occurs.

Cylindrical roller bearings, on the other hand, feature cylinder-shaped rollers. They excel in high-speed applications and provide excellent radial load capacity. However, they have limited axial load capacity and are less tolerant of misalignment compared to other types.

Spherical roller bearings are known for their spherical rollers and the ability to accommodate misalignment. These bearings are robust, handling heavy radial and axial loads simultaneously. They are commonly used in harsh environments like mining and construction machinery due to their durability and ability to function under oscillating conditions.

Understanding these differences is crucial for selecting the right bearing for specific applications, ensuring optimal performance and longevity in various industrial settings. This overview sets the stage for a deeper comparative analysis of their advantages and limitations.

Design and Construction

Toroidal Roller Bearings

Cylindrical Roller Bearings

Cylindrical roller bearings are characterized by their cylinder-shaped rollers, which enable them to handle high radial loads efficiently. These bearings typically consist of inner and outer rings with cylindrical raceways, along with cylindrical rollers held in place by a cage. The cylindrical design allows for uniform distribution of load across the rollers, promoting smooth operation and reducing friction. Additionally, cylindrical roller bearings come in various configurations, including single row, double row, and multi-row designs, offering versatility for different applications. The cage structure not only maintains proper roller spacing but also ensures stable performance under various operating conditions. Overall, the straightforward yet robust design of cylindrical roller bearings makes them a popular choice in industries ranging from automotive to manufacturing.

Spherical Roller Bearings

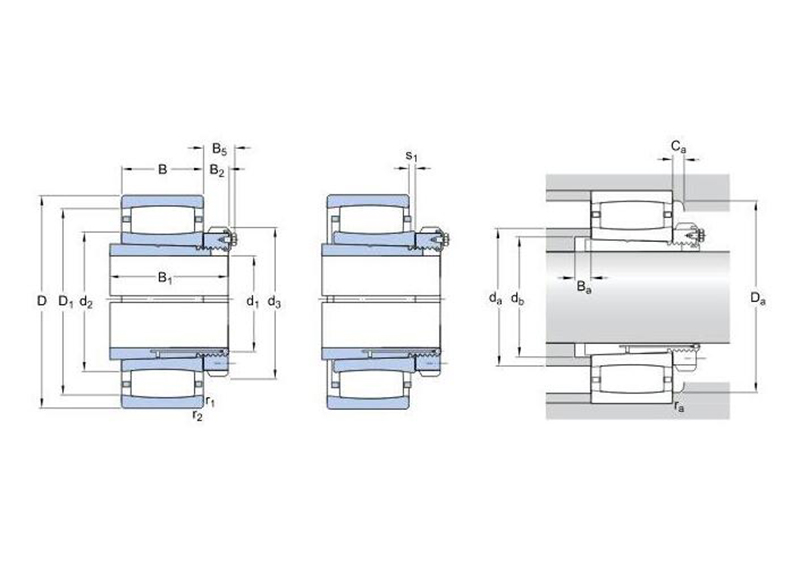

Spherical roller bearings feature spherical-shaped rollers, which allow them to accommodate misalignment and axial loads more effectively. These bearings typically consist of inner and outer rings with spherical raceways, along with barrel-shaped rollers and a cage to retain the rollers in position. The spherical design enables these bearings to operate smoothly even in applications where shaft misalignment or housing deflection is present. Additionally, the barrel-shaped rollers distribute the load evenly, reducing stress on individual components and enhancing overall durability. Spherical roller bearings come in various configurations, including straight bore and tapered bore designs, offering flexibility for different mounting arrangements. Overall, the robust construction and adaptability of spherical roller bearings make them suitable for demanding applications in industries such as mining, construction, and heavy machinery.

Load Capacity and Performance

Toroidal Roller Bearings

Toroidal roller bearings boast impressive load capacity and performance characteristics. Thanks to their unique toroidal shape, these bearings can handle both radial and axial loads with ease, making them highly versatile in various applications. Their flexible design allows for efficient load distribution, reducing stress on individual components and enhancing overall durability. Additionally, toroidal roller bearings exhibit high dynamic and static load ratings, ensuring reliable performance under heavy loads. Whether it’s in automotive, industrial machinery, or wind turbines, these bearings excel in demanding environments where robustness and efficiency are paramount. With their ability to accommodate misalignment and shaft deflection, toroidal roller bearings offer superior performance compared to other bearing types, making them a preferred choice for engineers and manufacturers looking to optimize their equipment’s reliability and longevity.

Other Roller Bearing Types

Cylindrical roller bearings exhibit robust load capacity and performance characteristics, particularly in handling radial loads. Their cylindrical shape allows for efficient distribution of radial forces, making them ideal for applications with heavy radial loads. However, they may have limitations in handling axial loads compared to other types like toroidal and spherical roller bearings. Spherical roller bearings, on the other hand, excel in handling both radial and axial loads simultaneously due to their barrel-shaped rollers and spherical raceways. This design enables them to accommodate misalignment and axial displacement, making them suitable for demanding applications in industries such as mining and construction. Despite differences in load capacity and performance among roller bearing types, each serves specific purposes and applications, allowing engineers to choose the most suitable option based on their equipment requirements and operational conditions.

Misalignment Tolerance

Misalignment tolerance plays a pivotal role in the performance and longevity of roller bearings across diverse industrial applications. Toroidal roller bearings stand out for their remarkable ability to adapt to misalignment scenarios. Their unique toroidal shape facilitates smooth operation even when confronted with shaft misalignment or housing deflection. This inherent flexibility not only ensures consistent performance but also mitigates the risk of premature wear and failure, thus enhancing the overall reliability of machinery and equipment.

Conversely, cylindrical roller bearings, while proficient in handling radial loads, exhibit a more restricted tolerance to misalignment compared to their toroidal and spherical counterparts. When subjected to misalignment beyond their design limits, cylindrical roller bearings may experience heightened stress concentrations, leading to accelerated wear and compromised performance. As a result, careful consideration must be given to the magnitude of potential misalignment when specifying cylindrical roller bearings for specific applications.

Spherical roller bearings, characterized by their barrel-shaped rollers and spherical raceways, excel in accommodating misalignment and axial displacement. This inherent capability makes them the preferred choice for applications where shaft deflection or misalignment is prevalent. By effectively distributing the load and minimizing stress concentrations, spherical roller bearings ensure reliable performance even in challenging operating conditions.

By comprehensively evaluating the misalignment tolerance of different roller bearing types, engineers can make informed decisions during the selection process.

Lubrication and Maintenance

Lubrication and maintenance are critical factors in ensuring the optimal performance and longevity of roller bearings. Toroidal roller bearings typically require high-quality lubrication to reduce friction and wear. Proper lubrication helps maintain their self-aligning capabilities, enhancing their overall efficiency and durability. Regular maintenance involves monitoring lubrication levels and ensuring the bearings are free from contaminants that could impair their performance.

Cylindrical roller bearings also demand diligent lubrication practices. Given their design, these bearings benefit significantly from consistent lubrication to handle high radial loads effectively. Maintenance routines for cylindrical roller bearings should include periodic inspection of the lubricant condition and replenishment as needed to prevent friction and overheating, which can lead to premature failure.

Spherical roller bearings, known for their robust construction, similarly rely on adequate lubrication to perform under heavy loads and misalignment conditions. Regular maintenance checks are essential to ensure that the bearings remain well-lubricated and free of debris. In addition to lubrication, maintenance practices should include inspecting for signs of wear or damage and replacing bearings when necessary to avoid unexpected downtime.

By prioritizing lubrication and maintenance, industries can significantly enhance the performance and lifespan of their roller bearings. Consistent care not only ensures smooth operation but also reduces the risk of bearing failure, contributing to improved reliability and efficiency in various applications.

Applications

Roller bearings find extensive applications across a wide range of industries, each type tailored to specific needs. Toroidal roller bearings are particularly favored in industries where misalignment and shaft deflection are common. For instance, they are used in automotive drivetrains, wind turbines, and industrial machinery, where their self-aligning capabilities and load-handling efficiency provide significant benefits.

Cylindrical roller bearings are prevalent in applications requiring high radial load capacity and precision. They are commonly found in machine tools, conveyor systems, and robotics. These bearings are well-suited for high-speed applications due to their ability to minimize friction and wear, ensuring smooth and efficient operation.

Spherical roller bearings, known for their ability to handle both heavy radial and axial loads, are ideal for demanding environments. They are widely used in mining equipment, construction machinery, and paper mills. The robust design of spherical roller bearings allows them to operate effectively under severe conditions, including misalignment and heavy load oscillations.

Each type of roller bearing is designed to meet the specific challenges of its application, providing reliability and performance where it’s needed most. By selecting the appropriate bearing type for each application, industries can optimize machinery performance, reduce downtime, and extend the lifespan of their equipment.

Environmental Factors

Environmental factors play a crucial role in the performance and longevity of roller bearings. Toroidal roller bearings are designed to perform well in challenging conditions, including high humidity, temperature fluctuations, and contaminated environments. Their robust design helps them maintain performance even when exposed to adverse conditions, making them suitable for industries such as wind energy and automotive, where environmental stresses are common.

Cylindrical roller bearings, while efficient in high-speed and precision applications, can be sensitive to environmental factors such as contamination and extreme temperatures. Ensuring that these bearings are properly sealed and lubricated is essential to protect them from dust, dirt, and moisture, which can cause premature wear and failure. Regular maintenance and environmental monitoring are critical to maintaining their performance and extending their service life.

Spherical roller bearings excel in harsh environments due to their ability to handle heavy loads and misalignment. They are often used in mining and construction, where they face exposure to dirt, debris, and heavy shocks. Their design allows them to function effectively under these conditions, providing reliable performance and durability.

By understanding the impact of environmental factors on different roller bearing types, industries can implement appropriate protective measures and maintenance routines. This proactive approach ensures optimal bearing performance, reduces the risk of unexpected failures, and enhances the overall reliability of machinery in various operating conditions.

Conclusion

In conclusion, selecting the appropriate roller bearing type is crucial for optimizing machinery performance and longevity. Toroidal roller bearings excel in accommodating misalignment and deflection, making them ideal for challenging environments. Cylindrical roller bearings offer excellent radial load capacity and high-speed performance, suitable for precision applications. Spherical roller bearings provide robust handling of heavy radial and axial loads, thriving in harsh conditions. Understanding each bearing type’s unique design, load capacity, misalignment tolerance, and environmental adaptability allows industries to make informed decisions, ensuring efficiency, reliability, and reduced downtime. By aligning bearing choices with specific application needs, industries can achieve enhanced performance and durability in their equipment.

References

- 1.”Toroidal roller bearings” from RKB;

- 2. “toroidal roller bearings” from thyssenkrupp rothe erde;

- 3. “CARB toroidal roller bearings” from SKF Bearings.