Bearing Housings

Table of Contents

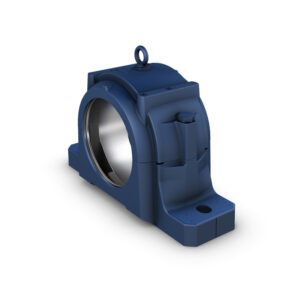

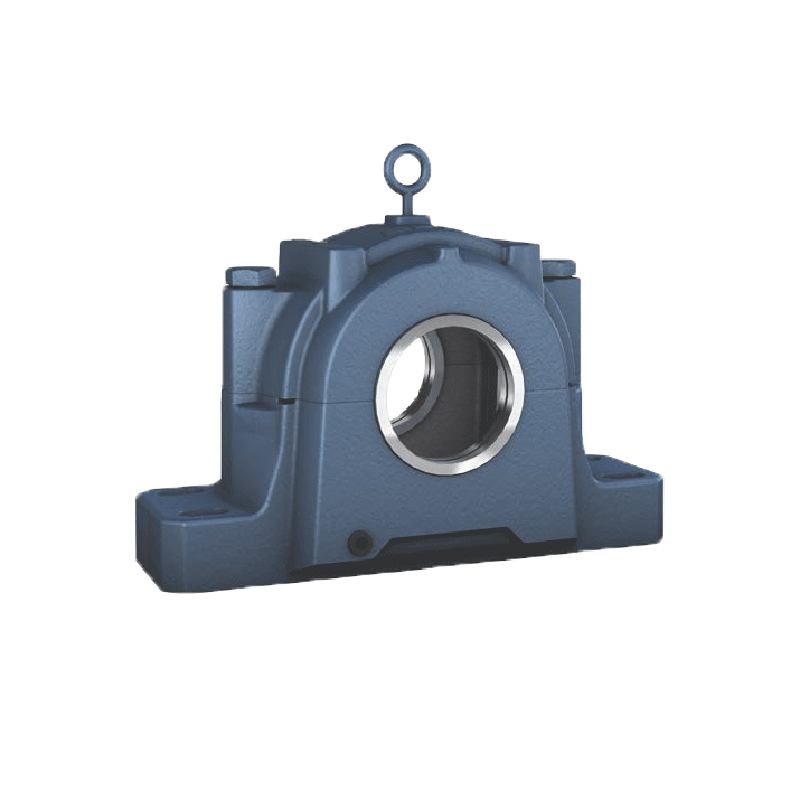

Definition of Bearing Housings

Bearing housings are protective enclosures that support bearings in machinery. These housings provide a secure environment, enhancing bearing performance and longevity. Designed to accommodate various bearing types, they play a crucial role in ensuring the smooth operation and reliability of mechanical systems.

FHD Bearings is an ISO 9001:2015 certified manufacturing enterprise that stocks a full range of Bearing Housings. With over 1,200 different bearing sizes and over 250K bearings in stock.

Materials of Bearing Housings

Cast Iron

Durable and heat-resistant, cast iron bearing housings are widely used in heavy-duty applications, providing robust support and stability.

Stainless Steel

Corrosion-resistant and hygienic, stainless steel housings are ideal for applications requiring resistance to rust and harsh environments.

Steel

Known for its strength and versatility, steel bearing housings offer excellent durability and are suitable for various industrial settings.

Aluminum

Lightweight and corrosion-resistant, aluminum housings are favored for applications where weight is a critical factor.

Bronze

Bronze bearing housings provide good corrosion resistance and are commonly used in specific applications where self-lubricating properties are essential.

Features of Bearing Housings

- Material and Construction: Bearing housings are typically made of materials such as cast iron, steel, or other alloys. The construction is designed to provide strength, durability, and resistance to environmental conditions.

- Mounting Arrangement: Bearing housings are designed to accommodate different types of bearings. The mounting arrangement ensures that the bearings fit securely within the housing, allowing for smooth rotation and load distribution.

- Modularity: Bearing housings are often modular, meaning they can be adapted to different bearing types and sizes, allowing for flexibility in their application.

- Lubrication Facilities: They often include features for lubrication, such as grease fittings or channels for oil lubrication, which are essential for reducing friction and wear in the bearing.

- Temperature Management: Some bearing housings are designed with features to manage temperature, especially in applications where high temperatures are expected. This may include cooling fins, heat dissipation channels, or other mechanisms to prevent overheating and maintain efficient operation.

Advantages of Bearing Housings

- Ease of Installation and Maintenance: Bearing housings simplify the mounting process, reducing the time and effort necessary for installation. They often come with easy-to-understand instructions for lubrication and maintenance, streamlining these operations.

- Cost-Effectiveness: Industries that rely on housed bearings can realize cost savings and improved operational efficiency. This is due to the reduced need for maintenance and the longevity of the bearings when housed.

- Increased Durability: Housed bearings are known for their load distribution capabilities and protective features, which contribute to increased durability. The housing protects the bearing from contaminants, thereby extending its lifespan.

- Adaptability: Bearing housings can be selected and configured for a wide variety of different applications. They can accommodate different types of bearings and are available in different styles, such as flange and pillow block.

- Vibration Isolation: Some bearing housings come with bushings, which are vibration isolators. They can absorb the vibrations produced by the parts with which they are used, contributing to the overall stability and smooth operation of the machinery.

Taxonomy of Bearing Housings

Bearing Housings

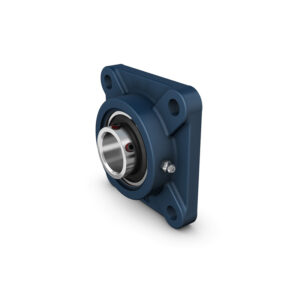

Flanged housings – FNL series

FNL flanged housings are well-proven machine parts that provide simple, reliable housing in applications without horizontal frames.

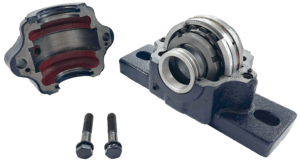

Split pillow blocks – SAF series

SAF and SAW split pillow blocks use a two-piece, cast metal housing with inch dimensions.

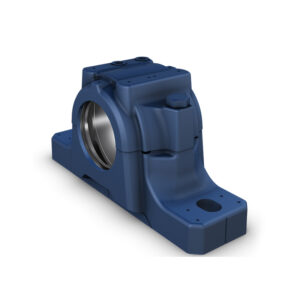

Split plummer (pillow) block housing, SNL 2, 3, 5 and 6 series

They enable the incorporated bearings to achieve maximum service life with less need for maintenance.

Split plummer (pillow) block housing, SNL 30, 31 and 32 series

SNL plummer (pillow) block housings in the 30, 31 and 32 series are robust and suitable for tough operating conditions.

Split plummer block housings – SNLN 30 series

They are designed for bearings in the 30 dimension series and can also accommodate some bearings in the 40 dimension series for mounting on a cylindrical shaft seat.

Split plummer block housings -SONL series

SONL plummer (pillow) block housings are specially designed for oil lubrication.They can accommodate high temperatures and bearings operating at high speeds.

Applications of Bearing Housings

- Industrial Machinery: Bearing housings are widely used in industrial machinery such as conveyors, pumps, fans, and compressors. They provide support and protection to the bearings, ensuring smooth and reliable operation of these machines.

- Automotive Industry: Linear bearings are employed in automotive manufacturing for tasks like robotic welding, assembly lines, and automated inspection systems. They contribute to the efficient and accurate movement of components.

- Agricultural Equipment: Bearing housings are employed in agricultural machinery, including tractors, harvesters, and irrigation systems. They help support and protect bearings in various components, facilitating the efficient functioning of agricultural equipment under demanding conditions.

- Mining Equipment: In the mining industry, bearing housings are used in equipment such as crushers, conveyors, and drilling machines. The housings provide a secure environment for bearings, ensuring reliable performance in harsh and challenging mining environments.

- Construction Machinery: Bearing housings are applied in construction machinery, including cranes, excavators, and concrete mixers. They support bearings in critical components, contributing to the durability and functionality of these heavy-duty machines used in construction projects.

Key Manufacturing Process of Bearing Housings

Casting or Machining of Housing Material

Many bearing housings are produced through casting processes. This involves melting the chosen material (often cast iron, steel, or alloys) and pouring it into molds to create the housing’s basic shape. Some housings may also undergo machining processes, where excess material is removed from a solid block to achieve the desired housing shape. This can involve processes like milling, turning, or drilling.

Heat Treatment

After casting or machining, bearing housings often undergo heat treatment processes to enhance their mechanical properties. Heat treatment can improve hardness, toughness, and overall structural integrity, ensuring the housing can withstand the loads and conditions it will face in operation.

Surface Finishing

The surfaces of bearing housings may undergo finishing processes such as grinding or polishing. This is done to achieve specific surface roughness, dimensional accuracy, and to improve the appearance of the housing.

Bore and Mounting Surface Machining

Precision machining is performed on the bore and mounting surfaces of the housing to ensure accurate dimensions and tight tolerances. This is crucial for proper fitting of bearings and alignment within the housing.

Assembly and Quality Control

After individual components are manufactured, the bearing housing is assembled. This involves fitting components together, including seals, lubrication systems, and other accessories. Quality control measures are implemented throughout the assembly process to check for dimensional accuracy, proper fit, and overall quality.

FAQ - Frequently Asked Questions

A bearing housing is a component that supports and encases a bearing, providing protection, support, and proper alignment within a machine or mechanical system.

Common materials for bearing housings include cast iron, steel, and various alloys, chosen for their strength, durability, and resistance to environmental conditions.

Bearing housings are manufactured through processes like casting or machining, followed by heat treatment, surface finishing, and precision machining of critical surfaces.

Heat treatment enhances the mechanical properties of bearing housings, improving hardness, toughness, and overall structural integrity to withstand operational loads.

Surface finishing, such as grinding or polishing, ensures smooth surfaces, specific roughness, and an improved appearance, contributing to overall performance and aesthetics.

Bearing housings provide a protective enclosure, shielding bearings from contaminants like dust and moisture, preventing premature wear and damage.

Precision machining of the bore and mounting surfaces ensures accurate dimensions and tight tolerances, facilitating proper fitting of bearings and alignment within the housing.

Yes, bearing housings are designed with versatility in mind and can accommodate various types and sizes of bearings to suit different applications.

Lubrication provisions, such as grease fittings or oil channels, are incorporated into bearing housings to ensure proper lubrication of the bearings for optimal performance.

Bearing housings find applications in industries such as automotive, industrial machinery, mining, agriculture, and construction.

Some bearing housings are equipped with temperature management features, such as cooling fins or heat dissipation mechanisms, to handle high-temperature conditions.

Bearing housings play a key role in distributing loads evenly across the bearing, reducing the risk of localized stress and improving overall stability and performance.

Yes, many bearing housings adhere to standardized dimensions, making them compatible with commonly used bearings and facilitating easier installation and replacement.

The lifespan of bearing housings depends on factors such as material quality, operating conditions, and maintenance. Proper care can significantly extend their operational life.

Yes, manufacturers often offer customization options for bearing housings to meet specific application requirements, including size, material, and design modifications.

Yes, regular maintenance, including lubrication checks and inspections for wear or damage, is important to ensure the continued reliability of bearing housings.

Seals in bearing housings prevent the entry of contaminants, enhancing the protection of bearings and contributing to their longevity.

Some bearing housings are designed with corrosion-resistant materials or coatings, making them suitable for use in corrosive environments.

Yes, manufacturers may implement eco-friendly practices in bearing housing production, such as recycling materials and reducing energy consumption.

Consider factors like load requirements, environmental conditions, and specific application needs. Consult with bearing housing suppliers or engineers for expert guidance on the most suitable choice.

Installation and Maintenance

Installation

- Preparation and Inspection: Inspect the bearing housing and components for any damage, corrosion, or defects before installation. Ensure that the shaft and surrounding components are clean and free from debris or contaminants. Verify that the bearing housing and associated parts match the specifications and requirements for the application.

- Alignment: Accurate alignment is crucial for the proper functioning of bearings. Use alignment tools to align the bearing housing with the shaft and other connected components. Check for parallelism and angular misalignment. Proper alignment minimizes wear and extends the life of the bearings. Follow the manufacturer’s recommendations for alignment tolerances and procedures.

- Lubrication: Apply the appropriate lubricant to the bearings and bearing housing according to the manufacturer’s specifications. Ensure that the lubrication method (grease, oil, etc.) is suitable for the application and operating conditions. Monitor the lubrication levels regularly and replenish as needed to prevent premature wear and failure.

- Mounting and Fastening: Carefully mount the bearing into the housing, making sure it is properly seated and aligned. Use the correct fasteners and torque values as specified by the manufacturer to secure the housing in place. Pay attention to the tightening sequence and evenly distribute the load to avoid misalignment or distortion.

- Sealing: Install appropriate seals to protect the bearings from contaminants and prevent lubricant leakage. Ensure that the seals are correctly aligned and securely in place. Verify that the sealing arrangement meets the environmental conditions of the application.

Maintenance

- Regular Lubrication: Ensure regular and proper lubrication of the bearings inside the housing. Follow the manufacturer’s guidelines for the type and amount of lubricant to be used. Monitor lubrication intervals and replenish as needed to prevent excessive wear and reduce friction.

- Vibration Monitoring: Implement a vibration monitoring program to detect any abnormal vibrations in the bearing housing. Regularly inspect and analyze vibration data to identify potential issues early on. Address any unusual vibration patterns promptly to prevent further damage to the bearings or housing.

- Seal Inspection and Replacement: Check the seals regularly for signs of wear, damage, or leakage. Replace damaged or worn seals promptly to prevent contamination and lubricant loss. Ensure that the seals are properly aligned and seated to maintain their effectiveness.

- Temperature Monitoring: Monitor the temperature of the bearing housing during operation. Sudden temperature spikes can indicate problems such as inadequate lubrication, misalignment, or excessive load. Investigate and address the root cause of temperature anomalies to prevent bearing and housing damage.

- Alignment Checks: Conduct periodic alignment checks to ensure that the bearing housing is properly aligned with the connected components. Misalignment can lead to increased friction, wear, and premature failure. Use precision alignment tools and follow the manufacturer’s recommendations for alignment tolerances.