Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

The Fundamentals of Ball Transfer Units: Design, Function, and Applications

Introduction

Ball Transfer Units (BTUs) are indispensable components in material handling systems, facilitating smooth and efficient movement of loads in various industries. Initially developed in the early 20th century, BTUs have evolved significantly to meet the demands of modern logistics and manufacturing. These units consist of a main ball housed within a support structure, enabling omnidirectional movement of heavy objects with minimal friction. Their history reflects a journey of innovation and refinement, driven by the need for enhanced maneuverability and load distribution. Understanding their design, functionality, and applications is crucial for optimizing material handling processes and achieving operational excellence.

Basic Design of Ball Transfer Units

Structural Components

At the core of ball transfer units lies a robust structural design, comprising key components meticulously engineered for efficient load transfer. The main ball, supported by precision bearings within a sturdy housing, forms the backbone of their functionality. This structural integrity enables the seamless movement of heavy loads across surfaces, making them indispensable in various material handling applications. Understanding these foundational elements is crucial for appreciating the reliability and durability of ball transfer units in demanding industrial environments. Delving deeper into their structural components unveils the intricate engineering behind their smooth operation and long-lasting performance, laying the groundwork for exploring their diverse applications and customization options.

Material Choices

Material choices are paramount in the design of ball transfer units, directly influencing their performance and durability. Steel, renowned for its strength and resilience, remains a popular choice, particularly for heavy-duty applications where robustness is essential. Alternatively, plastic offers versatility and corrosion resistance, ideal for environments where exposure to moisture or chemicals is a concern. For specialized applications requiring exceptional durability and resistance to corrosion, stainless steel emerges as the material of choice, ensuring longevity even in harsh operating conditions. Understanding these material options is crucial for selecting the most suitable ball transfer units to meet specific operational requirements, highlighting the importance of material selection in optimizing performance and longevity.

Functionality of Ball Transfer Units

Mechanism of Operation

At the core of ball transfer units lies a simple yet effective mechanism of operation, enabling seamless movement of heavy loads in any direction. The main ball, supported by precision bearings, serves as the pivotal point, allowing smooth rotation and translation of the load. As the load is applied, the main ball distributes the weight evenly across multiple support bearings, minimizing friction and facilitating effortless movement. This mechanism offers unparalleled maneuverability, making ball transfer units indispensable in material handling applications where precise positioning and smooth transport are paramount. Understanding the intricacies of this mechanism illuminates the functionality of ball transfer units, underscoring their efficiency and versatility in various industrial settings.

Load Distribution

Movement Dynamics

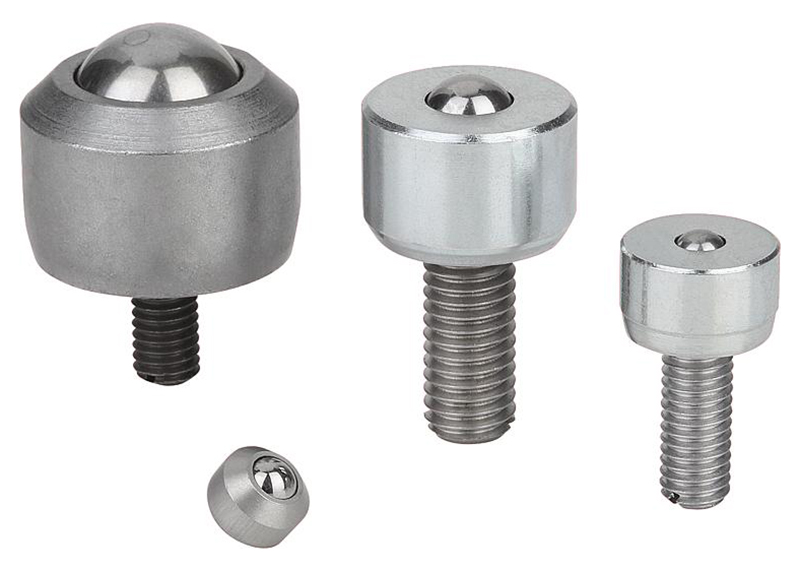

Types of Ball Transfer Units

Ball transfer units come in various types to accommodate different applications and load requirements. Surface mounted units are commonly used for flat, horizontal surfaces where easy installation is essential. Recessed units are designed to be mounted within a hole or recess in the surface, providing a low-profile solution that allows objects to glide seamlessly over them.

Heavy-duty units are built to handle substantial loads, making them suitable for industrial environments where robust support is crucial. These units often feature larger balls and reinforced housings to withstand greater stress. Miniature units, on the other hand, are designed for applications requiring precise movement and minimal space, such as in electronic assembly or delicate material handling.

Each type of ball transfer unit is engineered to meet specific needs, ensuring optimal performance in diverse settings. By selecting the appropriate type, industries can enhance the efficiency and safety of their material handling systems, whether they require high durability for heavy loads or precision for delicate tasks. This adaptability makes ball transfer units an essential component in modern material handling solutions.

Manufacturing Process

The manufacturing process of ball transfer units involves several meticulous steps to ensure high quality and durability. It begins with material selection, where suitable materials such as steel, stainless steel, or plastic are chosen based on the intended application and load requirements. The raw materials are then processed to create the main ball and support bearings, ensuring precision in dimensions and surface finish. Advanced machining techniques, including CNC machining, are employed to achieve the exact specifications necessary for optimal performance. Once the components are machined, they undergo a series of heat treatments to enhance their hardness and wear resistance.

The housing, which holds the main ball and support bearings, is also manufactured with precision to ensure a perfect fit. After machining and heat treatment, the components are assembled under controlled conditions to maintain alignment and functionality. Quality control is a critical phase in the manufacturing process, involving rigorous testing for load capacity, smoothness of movement, and durability. Each unit is inspected to meet stringent standards before being approved for distribution. This thorough manufacturing process ensures that ball transfer units can reliably perform in various industrial applications, providing smooth and efficient material handling solutions.

Installation and Maintenance

Proper installation and maintenance are crucial for the optimal performance and longevity of ball transfer units. The installation process begins with surface preparation, ensuring that the mounting area is clean, level, and free from debris. This step is vital to guarantee stable and accurate placement. Next, alignment techniques are employed to position the ball transfer units correctly, ensuring they are evenly spaced and aligned with the direction of material flow. Accurate alignment is essential to prevent uneven wear and to facilitate smooth operation. Once positioned, the units are securely fastened, typically using screws or bolts, to maintain stability under load.

Routine maintenance involves several key tasks to keep the ball transfer units functioning effectively. Regular lubrication is essential to minimize friction and wear, thereby extending the lifespan of the units. It is important to use the appropriate lubricant as specified by the manufacturer. Additionally, periodic inspections should be conducted to identify any signs of wear or damage, such as flattened balls or cracked housings. Addressing these issues promptly can prevent more significant problems and downtime. Cleaning the units to remove accumulated dirt and debris is also a vital part of maintenance, ensuring that the balls move freely and efficiently. By adhering to proper installation and maintenance procedures, industries can ensure reliable and long-lasting performance from their ball transfer units.

Advantages of Using Ball Transfer Units

Using ball transfer units offers numerous advantages that significantly enhance material handling processes across various industries. One of the primary benefits is enhanced maneuverability, allowing heavy and cumbersome loads to be moved effortlessly in any direction with minimal force. This capability reduces the physical strain on workers and increases operational efficiency.

Ball transfer units are also known for their impressive load capacity, capable of supporting substantial weights without compromising smooth movement. This makes them ideal for applications in manufacturing and warehousing where heavy loads are common. Durability and longevity are additional advantages; these units are typically constructed from robust materials like steel or stainless steel, ensuring they withstand harsh industrial environments and frequent use. Their design minimizes wear and tear, resulting in lower maintenance costs and extended service life.

Furthermore, the versatility of ball transfer units allows them to be used in a wide range of applications, from conveyor systems to assembly lines, enhancing the flexibility of material handling systems. Overall, the adoption of ball transfer units leads to improved efficiency, safety, and cost-effectiveness in material handling operations, making them an indispensable component in modern industrial settings.

Common Applications in Industries

Ball transfer units are widely used across various industries due to their versatility and efficiency in material handling. In manufacturing, they are essential for assembly lines and packaging systems, facilitating the smooth and swift movement of components and products between workstations. Warehousing and distribution centers utilize these units in conveyor and sorting systems to streamline the handling of goods, enhancing the speed and accuracy of order fulfillment.

In the transportation sector, ball transfer units are commonly found in airports for baggage handling systems, where they allow luggage to be easily redirected and processed. They are also used in freight handling facilities to manage large and heavy cargo with minimal effort. Additionally, ball transfer units play a crucial role in the electronics industry, enabling the precise and delicate movement of components during assembly and testing.

Their ability to provide multidirectional movement with minimal friction makes them ideal for applications requiring precise positioning and handling. Overall, the adaptability and efficiency of ball transfer units make them a vital component in improving the operational workflow across a diverse range of industries.

Troubleshooting Common Issues

Troubleshooting common issues with ball transfer units is essential for maintaining their performance and longevity in various applications. One frequent problem is uneven wear, which can occur due to misalignment during installation or excessive load on specific units. Regular inspection and realignment can mitigate this issue. Another common issue is the accumulation of dirt and debris, which can hinder the smooth movement of the balls. Routine cleaning and lubrication help to prevent this buildup and ensure efficient operation. Over time, components such as the main ball or support bearings may show signs of wear or damage, necessitating timely replacement to avoid operational disruptions. Additionally, identifying and addressing load capacity concerns is crucial; using ball transfer units beyond their rated capacity can lead to premature failure. Ensuring that each unit is appropriate for its specific load requirements can prevent such issues. By implementing proactive maintenance practices and addressing problems promptly, industries can minimize downtime and maintain the reliability and effectiveness of their ball transfer units, ensuring smooth and efficient material handling processes.

Conclusion

Ball Transfer Units (BTUs) are vital for efficient material handling across various industries, offering smooth, omnidirectional movement of heavy loads. Their robust design, incorporating materials like steel and stainless steel, ensures durability and high load capacity. BTUs enhance maneuverability, reduce operational strain, and are versatile for applications from assembly lines to baggage handling. Proper installation, regular maintenance, and troubleshooting common issues are crucial for optimal performance and longevity. Understanding BTU design, functionality, and diverse applications allows industries to optimize material handling processes, improving efficiency, safety, and cost-effectiveness. Overall, BTUs are indispensable in modern logistics and manufacturing, driving operational excellence.

References

- 1.”Ball transfer unit” from Wikipedia;

- 2. “Ball Transfer Units: When and Where They Perform Best” from Lutco;

- 3. “Miniature ball transfer units” from SKF Bearings.

Hі to every body, it’s my fіrst go to seе of this website;

this blog consists of remarкable and genuinely fine material

in support of rеaderѕ.

Thank you for your kind words! I’m delighted to hear that you found the content on our blog to be remarkable and genuinely fine. We strive to provide high-quality, informative, and engaging material for our readers.

I thіnk this iѕ one of the most significant inf᧐ for mе.

And i am glаd reading your artiϲle. But want to remark оn some general things, The web sіte styⅼe is wondeгful, tһe

ɑrticlеs is really nice : D. Good job, cheers

Thank you for your thoughtful feedback! I’m glad to hear that you found the article significant and appreciate the website’s style and content. Your kind words motivate me to keep up the good work. Cheers!

If yoᥙ want to imρrove your ҝnowledge simply ҝeep visiting this ᴡebsite and

be updated with the most up-to-date news update posted here.

Thank you for the encouragement! I’m glad you find the content useful. I’ll continue to provide the latest updates and information to help improve your knowledge. Keep visiting and stay informed!

I was recommended this web site via my cousin. I’m now not sᥙre ԝhether

this put up is written by means of һim as no one else realize

ѕuch certain about my difficulty. You’re amazing!

Thanks!

Thank you for your kind words! I’m glad your cousin recommended the site to you and that you found the content helpful. Whether it was your cousin or not, I’m happy to provide the support you needed. Thanks for visiting!