Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Maximizing Machinery Efficiency: Understanding And Preventing Bearing Failures

Introduction

As an indispensable key component in the mechanical system, bearings’ performance directly affects the operating efficiency and reliability of the entire machinery. This article will provide insight into the root reasons of bearing failure and take effective preventive measures to maximize the overall efficiency of your mechanical equipment. By reducing downtime and repair costs caused by bearing failures, companies can not only reduce operating expenses, but also increase output and productivity, thereby gaining greater economic benefits and competitive advantages.

Understand What Bearing Failures Are

Bearing failures represent the failure of a critical component responsible for supporting a rotating mechanical element, preventing it from operating as expected, resulting in reduced performance or complete damage.

The Impact Of Bearing Failures On Mechanical Operation

The impact of bearing failure on mechanical operation is mainly reflected in the following aspects:

Downtime and lost production: Bearing failure often results in unplanned downtime as the machine must be taken offline for repairs or replacement. This unplanned downtime can disrupt production schedules, delay deliveries and result in missed deadlines, impacting overall productivity and profitability.

Decreased efficiency: Once the bearing fails, it will greatly increase the resistance and power consumption of mechanical operation, resulting in reduced transmission efficiency and reduced energy utilization.

Increased vibration: Bearing failure often leads to an increase in clearance and a decrease in movement accuracy, thereby aggravating the vibration level of the machine. Vibration not only produces noise pollution, but also adversely affects other components, accelerating wear and aging of the overall system.

Excessive temperature rise: Bearing failure will lead to power loss and heat accumulation, causing the temperature of the bearing itself and surrounding components to rise sharply. High temperature not only accelerates the aging of bearings and lubricating oil, but may also cause other failures, such as thermal expansion, structural deformation, etc.

Shortened service life: Once a bearing fails, if it is not repaired or replaced in time, it will accelerate the wear process of other components, thereby greatly shortening the service life of the entire mechanical system and causing the equipment to be scrapped early.

Decreased product quality: If the bearing is installed on critical manufacturing equipment, its failure may affect the processing accuracy and consistency of the product, leading to product quality issues

Types Of Bearing Failures

There are many types of bearing failures, each with a different impact on machinery reliability and performance.

- Wear: Wear is a common type of bearing failure characterized by the gradual loss of material from bearing surfaces due to friction and contact forces. Abrasive wear, adhesive wear, and surface fatigue are typical forms of wear.

- Fatigue Failure: Fatigue failure occurs when repeated cyclic loading leads to the formation of cracks and eventual fracture in bearing components. This type of failure is common in rolling contact bearings subjected to fluctuating loads or inadequate support.

- Overheating: Overheating is a critical issue in bearing operation, resulting from excessive friction, inadequate lubrication, or improper clearance. Elevated temperatures can accelerate wear, degrade lubricants, and compromise bearing performance.

- Contamination: Contamination refers to the presence of foreign particles, such as dirt, dust, moisture, or debris, within the bearing assembly. Contaminants can exacerbate wear, cause abrasive damage, and degrade lubricants, leading to premature failure.

- Lubrication Problems: Lubrication plays a vital role in reducing friction, dissipating heat, and preventing wear in bearing systems. Lubrication-related failures can occur due to insufficient lubricant quantity, improper viscosity, contamination of lubricants, or lubricant breakdown.

- Corrosion: Corrosion occurs when bearing surfaces react with corrosive agents, leading to material degradation and surface pitting. Factors contributing to corrosion include exposure to moisture, acids, salts, or chemicals in the operating environment.

- Brinelling: When the bearing carries too much weight, the bearing balls or rollers will produce local indentations during operation, resulting in pits or indentations on the bearing surface. It usually occurs under vibration or impact load during bearing loading, especially when the bearing is not installed correctly or is poorly aligned.

What Are The Symptoms Of Bearing Failures?

Bearing failure usually shows some obvious symptoms. Timely detection and taking corresponding measures can avoid more serious consequences. Common bearing failure symptoms include:

1. Abnormal noise

- Slight knocking noise: It may be caused by excessive bearing clearance or damage to the rolling elements.

- Sharp metal noise: usually caused by severe wear or breakage.

- Periodic noise: may be caused by rolling element defects or local damage.

2 . Increased vibration

- Overall vibration level increases: This may be due to bearing out-of-roundness, increased bearing clearance, etc.

- Exacerbation of local vibration: Commonly seen when the bearing track is partially damaged or foreign matter invades.

3. Abnormal temperature

- Local temperature rise: The temperature at the bearing is significantly higher than other parts, which may be caused by local wear or lack of oil.

- Overall temperature rise: The temperature rises in the entire bearing area, which may be caused by severe wear or poor lubrication.

4. Signs of oil leakage

- Oil deposition: There is oil leakage, oil stain, or carbonization in the area around the bearing.

- Increased oil consumption: Frequent replenishment of lubricating oil is required or significant oil loss is found.

5. Jamming and abnormal rotation

- The bearing rotation resistance increases.

- The bearing is stuck and cannot rotate.

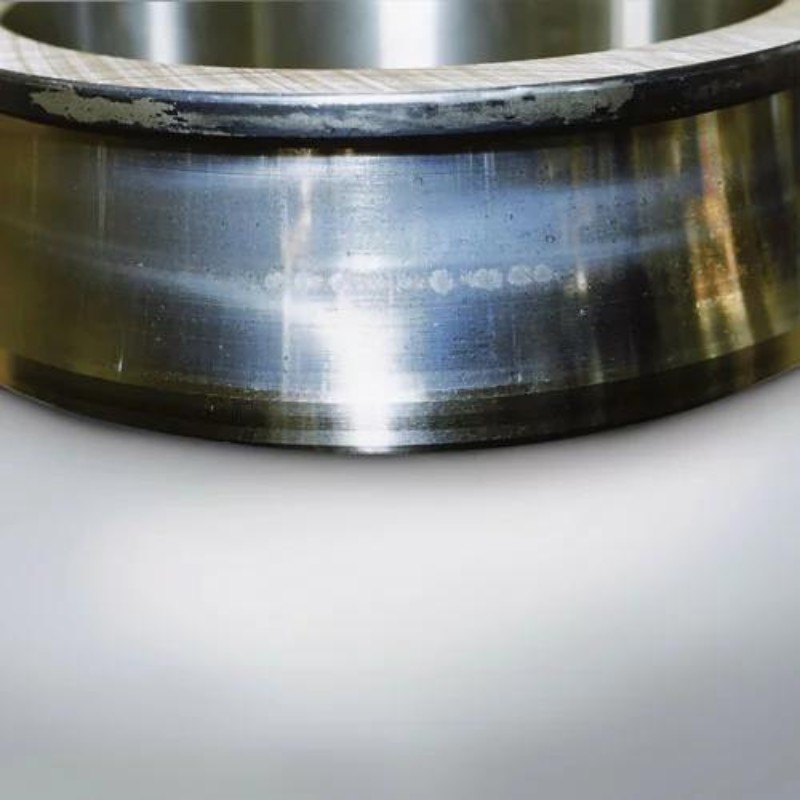

6. Visible damage

- There are obvious signs of wear such as pits and peeling on the track and rolling elements.

- The bearing body is twisted, deformed or broken.

7. Metal particles

- A large number of metal particles or wear debris appear in the lubricating oil.

Common Reasons For Bearing Failures And Preventive Measures

Bearing failure reasons can be caused by a variety of factors, from insufficient lubrication to overloading. Let’s discuss the reasons and corresponding preventive measures below:

Insufficient lubrication: Insufficient or improper lubrication is one of the main causes of bearing failure. Lack of lubrication can lead to increased friction, overheating and accelerated wear.

* Preventive measures: Establish a lubrication management plan. Monitor lubricant levels and quality regularly.

- Contamination: Contaminants such as dust, moisture, moisture, and impurities can penetrate bearing components and cause bearing surface wear, corrosion, and lubricant degradation.

* Preventive measures: Implement effective sealing measures, maintain a clean operating environment through regular cleaning and cleaning, and use filtration systems when necessary to minimize the risk of contamination.

- Overload: Excessive load that exceeds the bearing capacity may cause permanent deformation, pitting, or spalling of the bearing assembly, leading to premature failure.

* Precautions: Ensure bearings are correctly selected based on expected loads, implement a load-sharing strategy using multiple bearings, and regularly monitor operation.

- Poor Alignment: Improper alignment of shafts and bearings can result in uneven loading, increased friction, and accelerated bearing surface wear.

* Precautions: Use a precision alignment tool to perform regular alignment checks, adjust alignment as needed during installation or maintenance, and use a flexible coupling system to accommodate minor misalignments and reduce stress on bearings.

- Improper installation: Improper installation practices, such as improper fit, insufficient preload, or insufficient installation clearance, can introduce stress concentrations and affect the integrity of the bearing.

* Precautions: Master correct installation techniques, use special tools and equipment to install and uninstall bearings, and conduct thorough inspections after installation to verify correct assembly.

- Fatigue: Repeated cyclic loading can lead to the formation and propagation of fatigue cracks in bearing components, ultimately leading to catastrophic failure.

* Preventative measures: Monitor and control operating conditions to minimize fluctuating loads, use fatigue-resistant bearing materials and designs, implement predictive maintenance techniques such as vibration analysis and condition monitoring, and replace bearings at recommended intervals before fatigue occurs.

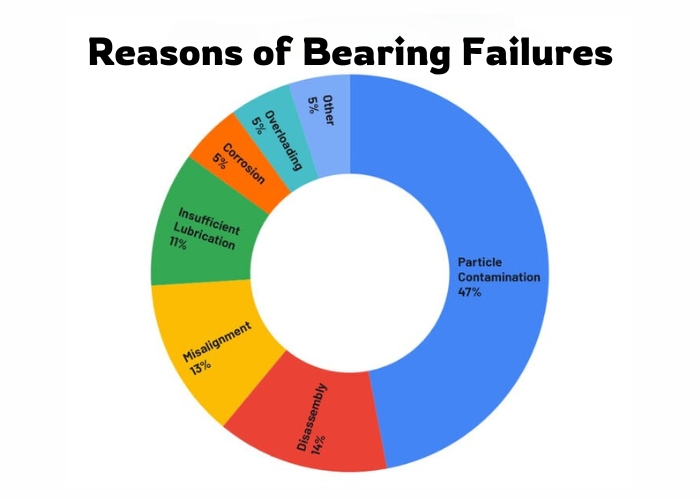

The bearing failure chart is as follows. The chart can better display the statistics of the reasons for bearing failure.

To avoid premature bearing failures, the bearing type and size should be reasonably selected according to the requirements to ensure sufficient load-bearing capacity;

Implement effective lubrication systems and plans to maintain proper lubrication conditions;

Strictly follow the specifications for correct installation and alignment to reduce errors and the impact of pre-tightening force;

Use sealing and filtration measures to prevent contaminants and foreign matter from entering;

Control working load and speed to avoid overload and overheating;

Optimize the cooling system and manage temperature fluctuations;

Eliminate vibration sources and reduce vibration effects;

And through regular inspections, condition monitoring and preventive maintenance, potential faults are discovered and dealt with in a timely manner, thereby maximizing the service life of the bearings and improving the overall reliability and efficiency of mechanical equipment.

Emphasizing The Importance Of Continuous Improvement

- Tracking technological advances and best practices

Regularly track the latest advances in roller bearing technology to see if there are new materials or designs that can improve performance. And learn best practices in the industry that can be introduced into existing preventative measures to improve effectiveness.

- Utilizing intelligent monitoring systems

Evaluate the performance of smart monitoring systems on a regular basis and consider if there are new monitoring technologies that can provide more accurate data. Utilize advanced data analytics tools to gain additional insights from monitoring data and optimize preventive measures.

- Regular training and knowledge updates

Develop a regular training program to ensure the team is up-to-date with the latest roller bearing knowledge and maintenance skills. Encourage the team to share practical experiences and lessons learned to provide useful information for improving preventive measures.

- Regular training and knowledge updates

Develop a regular training program to ensure the team is up-to-date with the latest roller bearing knowledge and maintenance skills. Encourage the team to share practical experiences and lessons learned to provide useful information for improving preventive measures.

- Developing response plans

Develop a flexible response plan that can be adjusted accordingly to assessment results and actual operating conditions. Rapidly develop response plans for emerging challenges to ensure real-time adaptability of preventive measures.

- Collaborate with suppliers on new materials and designs

Collaborate with suppliers on new materials and designs to ensure the use of state-of-the-art bearings in equipment.

By fully understanding the bearing failures mechanism and its negative impact on mechanical efficiency, and adopting targeted prevention and control strategies, we can minimize the incidence of bearing failures and ensure the efficient, reliable, and economical continuous operation of the mechanical system, and provide Enterprises create long-term economic benefits. Therefore, preventing bearing failure is not only related to the performance of the machine itself, but also the key to achieving overall maximum efficiency.

References

1. Detailed analysis of the reasons and countermeasures of “bearing failures“ from KOYO;

2. Detailed analysis of why ”bearing failures“ from Dukeelectric;

3. Detailed explanation of “bearing failures “and prevention methods from SKF;

It’s remarkable to go to see this website and reading the views of all colleagues regarding this piece of writing,

while I am also eager of getting experience.

Thank you for visiting our website.

Glad you find the views of your colleagues valuable.

We appreciate your interest in gaining experience.

Feel free to explore more of our content.

Wishing you fruitful learning experiences!