Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

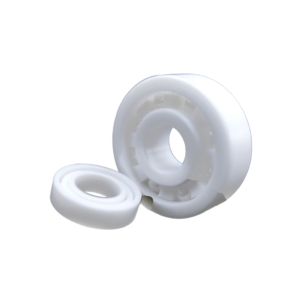

Ceramic Bearings (27)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Optimize Your Production Line By Choosing The Right Bearing Heater Type

Introduction

Bearings are core transmission components, and their installation quality directly affects product reliability. Improper installation methods will not only cause damage to the bearing itself, but may also lead to frequent equipment failures and shutdowns for maintenance, thereby significantly increasing operating costs.

In contrast, using a suitable bearing heater can accurately control the heating temperature, install the bearing through uniform and gentle thermal expansion and cold extrusion, avoid damage to the bearing to the greatest extent, ensure its accuracy and integrity, and fundamentally extend the entire machine service life. This not only helps to improve the first-time yield of products, but also effectively reduces downtime caused by equipment failure, thereby significantly improving the overall operating efficiency of the production line.

What Is A Bearing Heater And What Is It Used For?

A bearing heater is a device specially designed to heat bearings and other metal parts to facilitate their installation or removal. By applying heat, the inner diameter of the bearing expands slightly, allowing it to fit easily onto the shaft or journal, a process called hot fitting.

Hot assembly is an efficient and reliable assembly method. Compared with traditional mechanical press-fitting or knocking assembly methods, hot assembly can effectively avoid the use of traditional improper methods such as “brute force” or “impact” to install bearings and ensure the accuracy of bearings. and integrity. Hot assembly can significantly reduce the risk of damage to bearings and shafts during installation.

Main Uses Of Bearing Heater

Facilitates assembly of bearings and other metal components. By heating the bearing evenly, the bearing heater expands the bearing, simplifying the installation process and ensuring assembly accuracy and quality.

Reduce damage during installation. Compared with the cold mounting method, hot mounting can effectively avoid damage to the inner and outer rings of the bearing caused by excessive force.

Improve installation efficiency. Hot assembly is faster than traditional cold assembly methods and helps improve the overall efficiency of the production line.

Suitable for many sizes and types of bearings. Different types of bearing heaters are available for hot assembly of small bearings to large industrial bearings.

Types Of Bearing Heater

Bearing heaters can be mainly divided into three types: yoke, cone and heating plate, which are suitable for different heating scenarios and bearing types.

Yoke bearing heater

This heater consists of a U-shaped heating element with a hollow interior that can accommodate bearings. It is characterized by good heating uniformity and is suitable for rolling bearings with larger inner bore diameters.

By wrapping the bearing as a whole in a heating element, it is ensured that the bearing is heated evenly and local overheating deformation is avoided.

At the same time, the yoke structure makes the bearing easy to remove and assemble after heating. This kind of heater is often used to heat large bearings with an inner diameter of 100mm or more.

Cone bearing heater

As the name suggests, the heating element of a cone heater has a cone-shaped structure. This type of heater is suitable for bearings with smaller inner holes, especially deep groove ball bearings and angular contact ball bearings with small inner diameters and compact structures.

The cone structure allows the small-diameter bearing to pass smoothly through the larger inlet end and be heated, making it easy to operate during the heating process.

Heating plate

The heating plate is a flat-plate heating device whose heating surface is made of metal plate. It is mainly used for local heating of flat workpieces, such as heating journals for bearing assembly, or heating flange gaskets, etc.

The heating plate can be customized with different heating areas according to actual needs, and is suitable for heating small and medium-sized workpieces and their local areas. For larger workpieces, multiple heating plates can also be spliced together.

How To Know When You Should Use A Bearing Heater

Most rolling bearings need to maintain an excessively tight fit with the shaft or journal to ensure position accuracy and operational stability during transmission. However, an excessively tight fit will make it difficult for the bearing to be assembled directly into place.

At this time, you can use a bearing heater to preheat the bearing so that its inner diameter expands slightly, and you can easily install the bearing on the shaft to avoid damage caused by excessive use.

When installing large or heavy bearings, the installation is more complicated due to their size and weight. If the bearings are forcibly assembled using improper methods such as traditional “hammering” or “brute force”, it can easily cause problems such as deformation of the inner and outer rings of the bearing and damage to the rolling elements. Appropriate use of bearing heater can heat the bearings gently and evenly, making it easy to assemble the bearings after thermal expansion to avoid these damage hazards.

If the bearings and mating parts are not assembled properly, large radial clearance and excessive stress will be generated during operation, affecting transmission efficiency and accuracy, and accelerating wear. By using the precise heating of the bearing heater, the ideal fitting clearance can be obtained during assembly of the bearing, ensuring the assembly accuracy with the shaft or journal, thus ensuring the efficient and precise operation of the transmission system.

In addition to new bearing installation, when bearings that have been used for a period of time need to be disassembled, repaired or replaced, it is also suitable to use a heater to heat them and then disassemble them smoothly. Not only does it avoid bearing damage, it also eliminates the trouble of using other disassembly tools.

To What Degree Should Bearing Be heated?

Generally speaking, the ideal temperature range to which bearings should be heated is usually between 80°C and 120°C.

The selection of specific heating temperature mainly depends on factors such as the size, material and required assembly clearance of the bearing.

- For small or medium-sized bearings, heating to 100°C is usually sufficient.

- For large bearings, heating to 120°C may be required to ensure sufficient thermal expansion to make the installation process easier.

- Bearings of special materials (such as high-temperature alloys) may require higher heating temperatures, but they cannot exceed the temperature of the material-specific heat treatment.

It is important that the heating temperature does not exceed the safe operating temperature of the bearing material.

The Working Principles Of Bearing Heater

Bearing heaters mainly use two methods: electric induction heating and resistance heating.

Electric induction heating: Electric induction heaters use electromagnetic fields to generate heat, heating metal bearings by creating a rapidly changing magnetic field around the bearing.

This method heats the bearing quickly and evenly.

The advantage of electric induction heating is that it can achieve rapid and even heating while avoiding direct contact with the bearing, reducing the risk of damage.

Resistive Heating: Resistive heaters generate heat by passing an electric current directly through a heating element, which then transfers the heat to the bearings.

While this method is relatively simple, controlling heating temperature and uniformity can be more challenging than with electric induction heating.

In order to ensure uniform heating of the bearing and avoid local overheating, the heating temperature can be set and monitored, or the timing function can be set to automatically adjust the heating time.

Benefits Of Using Bearing Heater

Bearing heater provide a safe, controlled method of heating.

Different types of bearing heaters are designed with excellent heat distribution performance to ensure that the bearings can avoid local overheating and deformation and ensure overall dimensional accuracy.

Bearing heaters are generally equipped with temperature control and display systems, which can accurately set the optimal heating temperature according to the needs of different types of bearings. Precise temperature control helps achieve ideal thermal expansion and assembly.

The use of bearing heater can significantly improve assembly and maintenance efficiency;

Compared with arduous working methods such as manual hammering, the heater allows the bearings to be easily assembled or disassembled under thermal expansion, greatly reducing the difficulty of operation, without the need for special tools, and avoiding defective products and rework caused by “brute force” operations.

The most critical thing is that improper assembly methods can easily cause problems such as deformation of the inner and outer rings of the bearing and damage to the rolling elements. Bearing heaters can avoid these sources of damage and ensure the integrity and performance of the bearing to the maximum extent through gentle and precise assembly.

How To Choose A Suitable Bearing Heater

First, you need to understand the size, shape, and material of the heated bearing or other component.

Then choose the most suitable heater type based on the characteristics of the components. Yoke heaters are suitable for standard size bearings, cone heaters are suitable for larger bearings, and heated plates provide more flexibility for components with irregular shapes or exotic materials. And choose equipment that heats quickly and evenly to reduce wait times and prevent damage from overheating.

Also make sure the heater you choose has precise temperature control to prevent overheating and ensure heating.

It is important to note that preference is given to heaters that are easy to operate and safe, taking into account the device’s user interface and any built-in safety measures.

In addition to bearings, bearing heaters can also be used to heat journals, flexible diaphragms, flanges and flange gaskets, couplings and other components.

Conclusion

With a thorough understanding of the types of bearing heaters and their suitability, the most appropriate device can be selected based on specific application needs. Whether it’s a yoke, cone, or hot plate heater, each type has its own unique advantages to meet your basic needs.

Our commitment to providing high quality bearing heaters ensures that every customer can find the right solution for their production line.

References

- 1.Information and selection guide about ”bearing heater“ from Globalspec.

- 2. About” Heaters “for mounting and dismounting from SKF ;