Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

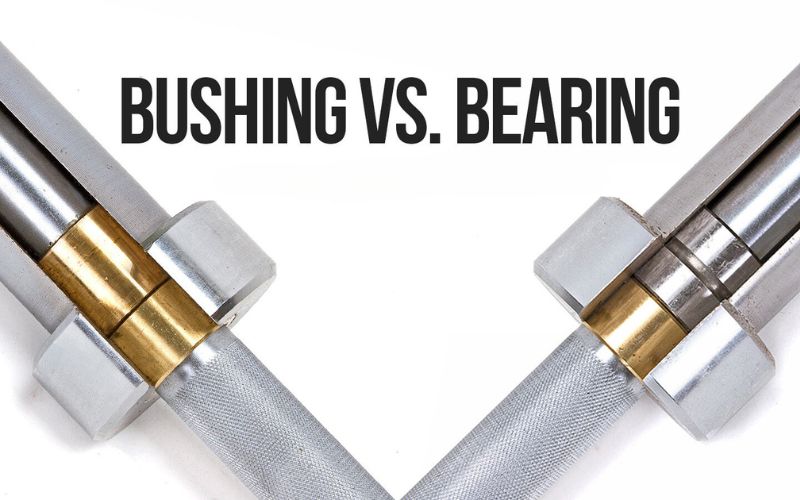

Bushings and Bearings: Key Differences Explained

In the realms of machinery and engineering, bushings and bearings serve pivotal roles in supporting moving parts. Despite their importance, the differences between these two components often lead to confusion. This article aims to clarify these differences and provide a comprehensive understanding of bushings and bearings.

What are Bearings?

Bearings are essential mechanical components designed to reduce friction between moving parts and support both axial and radial loads. Available in a wide range of shapes and sizes, bearings are typically crafted from robust materials such as steel or ceramic. This selection of materials is critical as it enables bearings to handle high speeds and heavy loads efficiently. Their durable construction ensures that they can operate under high-performance conditions for extended periods without significant wear and tear. Bearings are integral to applications such as motors, pumps, and compressors, where they facilitate smooth, high-speed operation and ensure the longevity and efficiency of the machinery.

Bearings work by minimizing friction between rotating parts, thereby reducing energy consumption and wear. They also help to maintain the correct alignment of rotating components, which is vital for the smooth operation of machinery. Bearings can be classified into several types, each suited to different applications and load conditions.

Common Bearing Types

- Ball Bearings: These are versatile and commonly used bearings that provide smooth, low-friction motion in a variety of applications.

- Roller Bearings: These bearings use cylindrical rollers instead of balls and are suitable for heavier loads and higher speed applications.

- Plain Bearings: Also known as bushings, plain bearings are simple and cost-effective, used in applications with low to moderate speeds and loads.

- Sleeve Bearings: These are a type of plain bearing, providing a simple solution for reducing friction and wear.

- Flange Bearings: These bearings have a flange on the outer ring, simplifying mounting and positioning.

- Thrust Bearings: Designed to handle axial loads, thrust bearings are used in applications where rotational force is transmitted along the axis of the shaft.

- Angular Contact Bearings: These bearings can handle both radial and axial loads, making them suitable for high-speed and high-precision applications.

- Tapered Roller Bearings: Ideal for applications requiring high load-bearing capacity, these bearings handle both radial and axial loads.

- Needle Bearings: With cylindrical rollers that are much longer than their diameter, needle bearings are suitable for applications with limited radial space.

- Spherical Roller Bearings: These bearings can accommodate misalignment and are used in applications with heavy radial and axial loads.

- Cylindrical Roller Bearings: Known for their high radial load capacity, these bearings are used in various industrial applications.

What are Bushings?

Bushings, also known as sleeve bearings, are cylindrical components typically made from softer materials like rubber, plastic, or bronze. They serve to cushion joints against shock and prevent direct metal-to-metal contact, thus reducing friction between moving parts. Bushings often have grooves that facilitate lubrication with oil or grease, enhancing their performance and longevity. They are ideal for applications requiring shock absorption and smooth rotational movement, often used in low-speed, high-load scenarios.

Bushings are designed to support and guide moving parts, ensuring smooth and efficient operation. They are used in a variety of applications, from automotive suspension systems to industrial machinery. The choice of material for bushings is critical, as it affects their performance, durability, and maintenance requirements.

Benefits of Bushings and Bearings

- Efficiency: By reducing friction, both components enhance the overall efficiency of machinery, leading to lower energy consumption and improved performance.

- Noise Reduction: Bushings and bearings help to lower noise levels during operation, contributing to a quieter working environment and reducing noise pollution.

- Durability: They extend the lifespan of machinery by reducing wear and tear on moving parts, which is crucial for maintaining the reliability and longevity of equipment.

- Safety: Improved shock absorption and reduced friction enhance operational safety, protecting both the machinery and the operators.

- Protection: By safeguarding the axle or shaft from excessive wear, both components ensure smooth movement and operation of machine parts, minimizing the risk of breakdowns and maintenance issues.

Best Materials for Bushings

The performance of a bushing largely depends on its material. Here are some common options:

- Bronze Bushings: Known for their durability and resistance to corrosion and deformation, bronze bushings require frequent lubrication, which can be high-maintenance. They are suitable for high-load and high-temperature applications.

- Plastic Bushings: Favored for their low cost, low friction, and minimal upkeep, plastic bushings are ideal for a wide range of applications. Being self-lubricating, they are particularly suitable for hard-to-reach areas and damp environments where traditional lubrication methods are impractical.

The choice of material for bushings should be based on the specific requirements of the application, including load capacity, operating environment, and maintenance needs.

Common Bushing Types

- Sleeve Bushings: These are the most basic type of bushings, providing a simple and cost-effective solution for reducing friction and wear.

- Flanged Bushings: These bushings have a flange at one end, making them easier to install and providing additional support to the assembly.

- Tapered Bushings: Used in applications where precise alignment and tight fit are required, tapered bushings offer excellent load distribution and stability.

- Spherical Bushings (Rod End Bearings): These bushings allow for angular misalignment and are commonly used in linkage applications.

- Linear Bushings (Linear Bearings): Designed for applications involving linear motion, these bushings provide smooth and accurate movement along a straight path.

- Oil-Impregnated Bushings (Self-Lubricating Bushings): These bushings are impregnated with lubricating oil, offering maintenance-free operation and extended lifespan.

Choosing Between Bushings and Bearings

When deciding whether to use bushings or bearings, consider the following factors:

- Speed and Load Capacity: Bearings are generally better for high-speed applications, as they can handle both radial and axial loads more efficiently. On the other hand, bushings excel in heavy-load, low-speed conditions, providing robust support and shock absorption.

- Operational Smoothness: Bearings typically offer smoother operation, with less friction and wear over time. Bushings may encounter “stick-slip” issues, which can affect performance in applications requiring precise and consistent movement.

- Noise Level: Bushings are usually quieter during operation, making them suitable for noise-sensitive environments where maintaining a low noise level is critical.

- Upkeep and Lubrication: In industries requiring low maintenance, such as food processing, self-lubricating bushings are preferable. Bearings, while often requiring more frequent lubrication, offer high performance and durability in demanding conditions.

- Cost Considerations: Bushings are often more economical than bearings, making them a budget-friendly option for many applications. When cost constraints are a significant factor, bushings provide a viable and effective solution.

Conclusion

Understanding the unique advantages of bushings and bearings is crucial for selecting the right component for your specific needs. Bearings are ideal for high-speed, high-load applications requiring long-term durability and precision. Conversely, bushings are suitable for less demanding applications and are a cost-effective solution for low-speed, high-load scenarios. The choice between bearings and bushings ultimately depends on the specific requirements of your application, including load capacity, speed, noise levels, maintenance needs, and budget constraints.

References

- 1.”Bearings And Bushings: The Inside Story” from Alpine Bearing;

- 2. “Composite Bushings & Bearings: 3 Benefits” from Advanced EMC Technologies;

3. “Bushing Vs Bearings – Everything You Need to Know” from Lily Bearing.

I discovered your blog web site on google and verify a few of your early posts. Continue to maintain up the excellent operate. I just further up your RSS feed to my MSN Information Reader. In search of forward to reading extra from you later on!…

Thank you for your kind words and for taking the time to visit our blog. We’re glad to hear that you found our content valuable. Your support by adding our RSS feed to your MSN News Reader is greatly appreciated. We are committed to consistently providing insightful content and look forward to sharing more with you in the future. If you have any specific topics you’d like us to cover, feel free to let us know.