Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

How a Cam Follower’s Structure Provides Greater Assembly Design Freedom

Introduction to Cam Followers

Definition of Cam Followers

A cam follower is a mechanical component designed to trace the profile of a cam, a rotating or oscillating disk that imparts reciprocating motion to another part. It typically consists of a rod, stud, or wheel with a rolling element, such as a roller or needle bearing, that makes contact with the cam surface. As the cam rotates, the follower moves in response to the cam’s irregularities, translating the cam’s rotational motion into linear motion. Cam followers are commonly used in various machinery and engines where precise and controlled movement is required, facilitating applications in automotive engines, industrial equipment, and other mechanical systems. Their design ensures efficient transmission of motion and helps maintain a stable and predictable motion output.

Brief History and Evolution of Cam Followers

The history of cam followers dates back to the industrial revolution when the need for precise and controlled motion in machinery became evident. Early cam followers were simple and comprised a basic rod or lever, manually operated to follow the cam’s profile. As technology advanced, the design evolved to incorporate rolling elements like rollers or needle bearings, enhancing efficiency and reducing friction. In the mid-20th century, the development of high-performance materials and manufacturing processes further improved cam follower designs, enabling their widespread adoption in various industries. Today, modern cam followers boast sophisticated engineering, with considerations for materials, lubrication, and design intricacies, making them integral components in diverse applications, from automotive systems to industrial machinery.

The Basic Structure of a Cam Follower

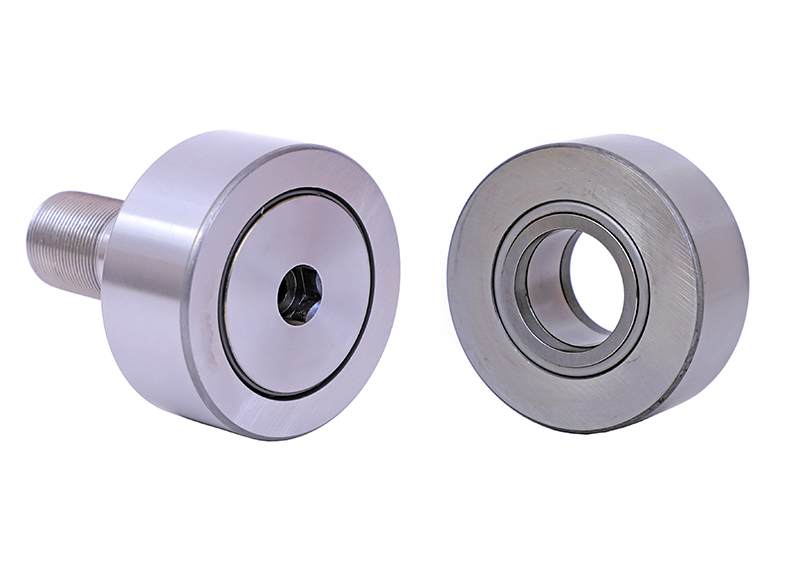

Components of a Cam Follower

A cam follower typically consists of several key components designed to facilitate its function in translating the rotational motion of a cam into linear motion. The main body of the cam follower often takes the form of a rod, stud, or wheel, providing a structural framework for the assembly. The crucial element is the rolling component, such as a roller or needle bearing, which makes direct contact with the cam’s surface, ensuring smooth motion transfer. A housing or outer ring encases the rolling element, providing support and maintaining proper alignment. Additionally, seals or shields may be incorporated to protect the rolling elements from contaminants, enhancing durability and longevity. The combination of these components in a well-engineered cam follower allows for precise and reliable transmission of motion in various mechanical applications.

Different Types of Cam Followers

Cam followers come in various types, each tailored to specific applications and operational requirements. Stud-type cam followers have a threaded rod extending from the body, making them suitable for applications where easy installation and adjustment are crucial. Yoke-type cam followers, on the other hand, feature a yoke-shaped design, providing increased stability and support, making them well-suited for heavy-duty applications. Crowned cam followers have a slightly curved outer surface, enhancing their ability to handle misalignment and uneven loading. Track followers, designed with an outer ring to roll on tracks, find utility in applications like conveyor systems. Additionally, eccentric stud cam followers incorporate an eccentric collar for adjustable axial positioning, offering versatility in applications requiring fine-tuned adjustments. These diverse types of cam followers cater to a wide range of industrial needs, ensuring optimal performance and efficiency in various mechanical systems.

Understanding the Role of Cam Followers in Assembly Design

General Functions of Cam Followers

A cam follower bearing serves the crucial function of translating rotational motion into linear motion in mechanical systems. It achieves this by closely following the profile of a cam, a rotating or oscillating disk. The bearing typically consists of a rod, stud, or wheel with a rolling element, such as a roller or needle bearing, making direct contact with the cam surface. As the cam rotates, the cam follower bearing moves accordingly, converting the rotational movement into a controlled linear motion. This conversion is vital in various applications, including automotive engines, industrial machinery, and conveyor systems, where precise and predictable linear motion is essential for the proper functioning of the equipment.

Importance of Cam Followers in Assembly Design

Cam followers play a pivotal role in assembly design, offering several key advantages that contribute to the overall efficiency and reliability of mechanical systems. Their ability to convert rotational motion into linear motion makes them indispensable in applications requiring precise and controlled movement, ensuring proper alignment and functionality of assembled components. The use of cam followers reduces friction and wear, enhancing the longevity and durability of the assembly. Moreover, their versatility allows for customization based on specific operational needs, accommodating variations in load, speed, and environmental conditions. In assembly design, cam followers contribute to smoother operation, reduced energy consumption, and improved overall performance, making them integral components in a wide range of industries, from automotive and aerospace to manufacturing and robotics.

How Cam Followers Provide Design Freedom

Cam followers significantly enhance design freedom by embodying inherent design flexibility and remarkable versatility in applications. Their diverse types, including stud-type, yoke-type, crowned, and eccentric stud cam followers, offer engineers a spectrum of choices to suit specific mechanical needs. This variety allows for optimal customization in various systems, granting designers the flexibility to select the most fitting configuration for a given application. The adaptability of cam followers to handle misalignments, varying loads, and distinct environmental conditions further underscores their design flexibility.

Moreover, the versatility of cam followers extends to a wide range of applications, from automotive engines to industrial machinery and conveyor systems. Their ability to convert rotational motion into precise linear motion ensures dependable performance across diverse contexts. This versatility not only addresses specific design challenges but also provides engineers with the freedom to innovate and optimize motion control solutions, making cam followers indispensable components for achieving design objectives in a multitude of applications.

The Impact of Cam Follower's Structure on Load Capacity

Load Distribution in Cam Followers

The load on a cam follower is distributed across its rolling elements, typically composed of rollers or needle bearings. This distribution of load is crucial for optimizing the performance and longevity of the cam follower in mechanical systems. As the cam follower follows the profile of a cam, the rolling elements make contact with the cam surface, and the load is evenly distributed among them. This uniform distribution minimizes stress on individual components, reducing wear and ensuring a more extended operational life. Effective load distribution is especially significant in applications with variable loads or sudden force changes, contributing to smoother motion, increased efficiency, and enhanced overall durability of the cam follower within the mechanical system it serves.

How Structure Influences Load Capacity

The construction of a cam follower significantly influences its load capacity in mechanical applications. The choice of materials, design, and the incorporation of features such as roller or needle bearings play a crucial role in determining the load-bearing capabilities of the cam follower. High-quality materials and precision engineering enhance the strength and durability of the cam follower, enabling it to withstand heavier loads and prolonged usage. The type of construction also affects the distribution of loads across the rolling elements, ensuring that forces are evenly managed. In essence, a well-constructed cam follower, with considerations for robust materials and effective design, enhances its load capacity, providing reliability and efficiency in diverse applications where precise motion control under varying loads is essential.

The Role of Cam Follower's Structure in Reducing Friction

The construction of a cam follower plays a pivotal role in minimizing friction within mechanical systems. Key design elements such as the choice of materials and the incorporation of rolling elements like rollers or needle bearings contribute significantly to friction reduction. High-quality materials with low friction coefficients and precision engineering reduce the resistance between the cam follower and the cam surface. Additionally, the use of rolling elements ensures smooth contact and motion, minimizing sliding friction. Well-designed cam followers with low-friction construction enhance the overall efficiency of the system by reducing energy losses and wear. This is particularly crucial in applications where precise and controlled motion is essential, as lower friction not only improves performance but also contributes to the longevity of the cam follower and the efficiency of the entire mechanical assembly.

The Influence of Cam Follower's Structure on Speed and Efficiency

The construction of a cam follower significantly influences the speed and efficiency of mechanical systems. Well-designed cam followers, incorporating features like precision engineering, high-quality materials, and optimized rolling elements, contribute to reduced friction and smoother motion. Lower friction leads to less energy dissipation, allowing for higher speeds without compromising efficiency. The choice of materials and construction also impacts the cam follower’s ability to handle varying loads, ensuring consistent and reliable performance across different operational conditions. Additionally, efficient construction minimizes wear and tear, contributing to the longevity of the cam follower and the overall system. In essence, a carefully constructed cam follower enhances both the speed and efficiency of mechanical systems by providing reliable and precise motion control, making it a crucial component in diverse applications, from automotive systems to industrial machinery.

Tips for Choosing the Right Cam Follower for Your Assembly Design

When selecting a cam follower, several factors should be considered to ensure optimal performance in a given application. Critical considerations include load capacity, speed requirements, and environmental conditions. Evaluating the type of motion, whether oscillating or rotary, and understanding the necessary precision are essential. Common mistakes to avoid include overlooking load and speed requirements, as selecting a cam follower with insufficient capacity can lead to premature failure. Ignoring environmental factors, such as temperature and contamination risks, can also impact performance negatively. Inaccurate assessments of the application’s motion characteristics may result in a mismatch between the cam follower type and the system’s needs. Careful consideration of these factors and avoiding common mistakes are crucial for choosing the right cam follower, ensuring reliability, longevity, and efficient motion control in diverse mechanical systems.

Conclusion

In conclusion, cam followers play a pivotal role in providing assembly design freedom through their inherent design flexibility and versatility. The diverse types of cam followers available, such as stud-type, yoke-type, crowned, and eccentric stud cam followers, offer engineers a wide range of options to tailor motion control solutions to specific mechanical requirements. Their adaptability to handle misalignments, varying loads, and different environmental conditions enhances overall design flexibility. Moreover, the construction of cam followers, including the choice of materials and incorporation of features like rolling elements, contributes to load distribution, friction reduction, and increased efficiency. This combination of design features empowers engineers with the freedom to innovate and optimize assembly designs across various industries, making cam followers indispensable components for achieving design objectives and ensuring the reliability and longevity of mechanical systems.

References

- 1.”Cam follower” from Wikipedia;

- 2. “Cam Follower” from IKO International;

- 3. “Cam followers” from SKF Bearings.