Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

How to Choose the Right Sleeve Bearing for Your Project

Introduction

Sleeve bearings are crucial components in machinery, providing low-friction support for rotating or sliding parts. Their reliability ensures smooth operation and prolongs the lifespan of equipment. When choosing the right sleeve bearing for your project, it’s essential to consider factors like load capacity, operating speed, and temperature. Material selection, environmental conditions, and lubrication requirements also play significant roles. Proper installation and maintenance are key to maximizing performance and durability. Understanding these factors helps in selecting the most suitable sleeve bearing, ensuring efficient and trouble-free operation of your machinery.

Understanding Sleeve Bearings

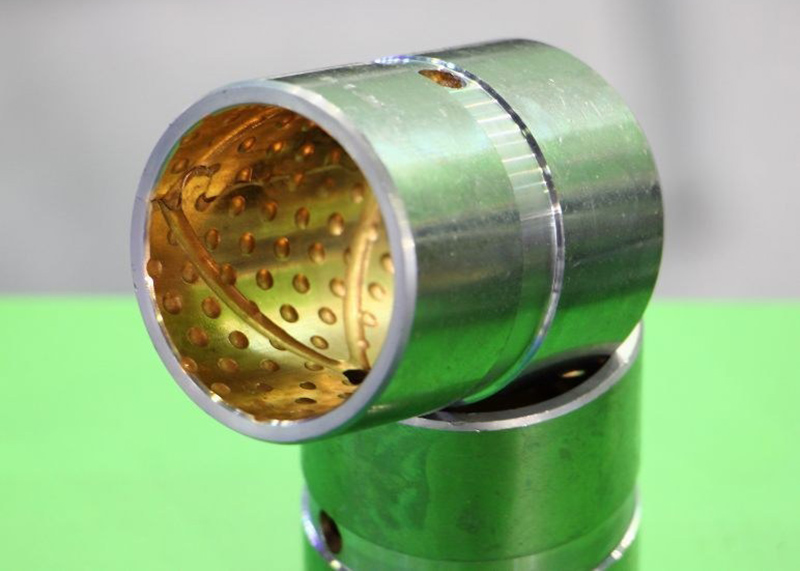

Sleeve bearings, also known as bushings, are essential components in machinery, providing low-friction support for rotating or sliding parts. They come in various types, including plain, flanged, and thrust bearings, each serving specific purposes in different applications. Sleeve bearings operate by providing a sliding surface between the shaft and the bearing, reducing friction and wear. They are commonly made from materials like bronze, steel, or nylon, selected based on the application’s demands for load capacity, operating speed, and environmental conditions. Understanding the basic functioning and types of sleeve bearings is crucial for selecting the right one for a project, ensuring smooth and efficient machinery operation.

The Pros and Cons of Sleeve Bearings Compared to Other Bearing Types

Sleeve bearings offer several advantages and disadvantages compared to other bearing types. One major advantage is their simplicity and cost-effectiveness. Sleeve bearings have a straightforward design, consisting of a cylindrical sleeve that slides over the shaft, making them relatively easy to manufacture and install. Additionally, they tend to be more affordable than other bearing types, making them a popular choice for many applications, especially those with budget constraints.

However, sleeve bearings also have some limitations. One significant drawback is their lower load capacity compared to other bearing types like ball bearings or roller bearings. Sleeve bearings are better suited for lighter loads and lower speeds, as excessive loads can cause increased friction and wear, leading to premature failure. Additionally, sleeve bearings typically require more frequent lubrication compared to other bearing types, as they rely on a film of lubricant to reduce friction between the shaft and the bearing surface.

Despite these drawbacks, sleeve bearings remain a popular choice for many applications where cost-effectiveness and simplicity are prioritized over high load capacity and speed capabilities. Understanding the pros and cons of sleeve bearings compared to other bearing types helps in making informed decisions when selecting the most suitable bearing for a particular project or machinery.

Factors to Consider

- Load Capacity:When selecting a sleeve bearing, load capacity is a critical factor. First, determine the load requirements of your application. Bearings must support the weight and forces exerted during operation without deforming or failing. Calculate the load capacity for different bearing materials, as each material has unique strengths and limitations. For example, bronze bearings can handle higher loads than nylon ones. Ensuring the bearing’s load capacity matches or exceeds the application’s demands is crucial for reliable performance and longevity.

- Operating Speed:Operating speed is another vital factor when choosing a sleeve bearing. The speed at which your machinery operates affects the bearing’s performance and lifespan. Exceeding the recommended maximum speed for a particular bearing material can lead to overheating and premature wear. It’s essential to consider the impact of speed on bearing performance and select a bearing that can handle the operational speeds of your equipment. This ensures smooth operation and prevents potential damage or failure due to excessive speeds.

- Operating Temperature:Operating temperature is a critical consideration when selecting a sleeve bearing. Different materials have varying temperature tolerances, and it’s essential to choose a bearing material that can withstand the temperatures present in your application. High temperatures can cause bearing materials to degrade or lose their lubricating properties, leading to premature failure. Conversely, operating at low temperatures can affect the bearing’s ability to maintain proper lubrication.

- Lubrication Requirements:Proper lubrication reduces friction and wear, extending the bearing’s lifespan. Different bearings require different types and amounts of lubrication, whether oil, grease, or solid lubricants. Consider the ease of applying and maintaining lubrication in your specific application. Regularly checking and replenishing lubricant is key to ensuring smooth operation. Choosing the right lubrication strategy helps prevent overheating and premature bearing failure, keeping your machinery running efficiently.

- Environmental Conditions:Factors like moisture, dust, and exposure to chemicals can affect bearing performance and longevity. Choose bearing materials that resist corrosion if they will be used in wet or humid environments. For dusty or dirty settings, consider bearings with seals or shields to prevent contaminants from entering. Ensuring the bearing material and design can withstand specific environmental challenges is crucial for reliable and long-lasting performance.

- Installation and Maintenance:Incorrect installation can lead to misalignment and premature wear. Follow manufacturer guidelines to ensure a correct fit. Regular maintenance, such as inspecting for wear and applying lubrication, extends bearing life. Scheduled maintenance checks help catch issues early, preventing costly downtime. Prioritizing proper installation and consistent maintenance keeps your machinery running smoothly and efficiently.

Material Selection

Choosing the right material for sleeve bearings is crucial, with bronze, steel, and nylon being popular options.

Bronze bearings are known for their durability and excellent load-carrying capacity. They perform well under heavy loads and high temperatures, making them suitable for demanding applications like automotive engines and heavy machinery. Their resistance to wear and corrosion adds to their longevity, although they can be more expensive than other options.

Steel bearings offer high strength and are ideal for high-load, low-speed applications. They are less prone to deformation under heavy loads and provide good performance in harsh environments. However, they can be prone to corrosion if not properly lubricated and maintained.

Nylon bearings are lightweight and have excellent resistance to wear and corrosion. They are suitable for applications where noise reduction and low friction are important, such as in HVAC systems and household appliances. Nylon bearings are also cost-effective, but they may not be the best choice for high-load or high-temperature applications.

Selecting the right material involves considering the specific demands of your application, balancing factors like load capacity, operating conditions, and budget.

Size Considerations

Inner and Outer Diameter

When selecting a sleeve bearing, the inner and outer diameter are crucial factors.

The inner diameter must match the shaft size to ensure a proper fit. Too tight, and it can cause excessive friction and wear; too loose, and it might lead to misalignment and instability. It’s important to measure the shaft accurately and choose a bearing with a matching inner diameter.

The outer diameter should fit snugly into the housing or bore. Proper clearance or interference fit is essential for maintaining stability and performance. A bearing that’s too large can be difficult to install and might damage the housing, while one that’s too small can move around and cause operational issues.

Paying attention to these size considerations ensures the bearing functions smoothly, providing reliable support and reducing the risk of mechanical failure.

Length and Wall Thickness

Wall thickness affects the bearing’s strength and load-carrying capacity. Thicker walls can handle higher loads but may require more space and add weight. On the other hand, thinner walls are suitable for lighter applications and compact spaces but might not support heavy loads effectively.

Balancing the length and wall thickness according to your project’s needs ensures the bearing performs efficiently, providing reliable support without compromising on space or weight constraints.

Application-Specific Considerations

When choosing a sleeve bearing, application-specific considerations are key.

In the automotive industry, bearings need to withstand high temperatures and heavy loads, making bronze or steel ideal for engine and suspension systems. For HVAC systems, bearings should prioritize quiet operation and resistance to corrosion, so nylon or specially coated bearings work well.

In industrial machinery, where bearings face extreme conditions and heavy-duty use, durability and load capacity are crucial. Steel or bronze bearings are often the best choice due to their robustness and ability to handle high loads and temperatures.

Each application has unique demands, and selecting the right bearing involves understanding these specific requirements. By focusing on the particular needs of your project, whether it’s load capacity, environmental resistance, or operational noise, you can ensure optimal performance and longevity of the machinery.

Cost Considerations

Cost considerations are essential when choosing a sleeve bearing.

While it might be tempting to opt for the cheapest option, it’s important to balance initial costs with long-term expenses. Bearings made from high-quality materials like bronze or steel may have a higher upfront cost, but their durability and performance can reduce maintenance and replacement costs over time. Conversely, more affordable materials like nylon can be cost-effective for low-load, low-speed applications, but might not last as long in demanding environments.

Evaluating the total cost of ownership is crucial. This includes not only the purchase price but also installation, maintenance, and potential downtime costs. Investing in a higher-quality bearing that matches your application’s needs can lead to savings in the long run by preventing unexpected failures and ensuring smooth, reliable operation.

Carefully considering both short-term and long-term costs helps you make a smart, cost-effective decision for your project.

Testing and Quality Assurance

Testing and quality assurance are crucial steps in sleeve bearing selection to ensure reliability and performance.

Manufacturers conduct various tests to validate the quality and durability of their bearings, including material strength tests, dimensional inspections, and performance evaluations under different operating conditions. These tests help identify any defects or weaknesses in the bearings before they are installed in machinery, reducing the risk of unexpected failures and downtime.

Quality assurance processes, such as ISO certification and adherence to industry standards, provide further assurance of the bearing’s quality and consistency. It’s essential to choose suppliers who prioritize quality assurance to ensure you’re getting reliable bearings for your project.

Additionally, conducting your own tests or performance evaluations can provide valuable insights into the suitability of a particular bearing for your specific application. By investing in quality-assured bearings and conducting thorough testing, you can minimize risks and ensure the smooth operation of your machinery.

Conclusion

In conclusion, sleeve bearings are indispensable components in machinery, offering a balance of simplicity, cost-effectiveness, and performance. Understanding factors like load capacity, operating speed, material selection, and environmental conditions is crucial for selecting the right bearing for optimal performance and longevity. While sleeve bearings have limitations compared to other types, their suitability for various applications makes them a popular choice. By prioritizing proper installation, maintenance, and quality assurance, you can ensure smooth and efficient machinery operation while balancing short-term costs with long-term reliability. With careful consideration and informed decision-making, selecting the most suitable sleeve bearing ensures trouble-free operation and maximizes the lifespan of your equipment.

References

- 1.”Sleeve Bearing vs.Ball Bearing” from Pacific International Bearing;

- 2. “What is a Sleeve Bearing?” from ISK Bearing;

- 3. “Plain Bearings and Sleeve Bearings Information” from GlobalSpec.