Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Power Up Your Engine: Understanding Connecting Rod Bearings

Introduction

In modern automotive engineering, every detail part is crucial. The engine is the key component that drives the car forward, and the connecting rod bearing is one of the key parts of the engine that converts and transmits to produce great power. Connecting rod bearings are located in the heart of the engine, connecting the piston and the crankshaft, ensuring that the power of the piston movement can be smoothly and efficiently converted into the rotational power of the crankshaft. Therefore, their performance directly affects the efficiency, durability, and fuel economy of the entire engine. In this article, we will discuss connecting rod bearings in depth, so that we can better grasp the pulse of the development of engine technology.

Understanding Connecting Rod Bearings

Definition of connecting rod bearings

A connecting rod bearing is a special type of plain bearing mainly mounted between the connecting rod and the crankshaft of an internal combustion engine.

Its basic function is to support the connecting rod, allowing it to rotate smoothly on the crankpin while reducing direct friction between the metals. In this way, the connecting rod bearing helps convert the reciprocating motion of the piston into the rotating motion of the crankshaft, which is the core process of generating power in an engine.

Connecting rod bearings must be extremely resistant to wear and fatigue strength, as they operate continuously at high speeds, temperatures, and loads.

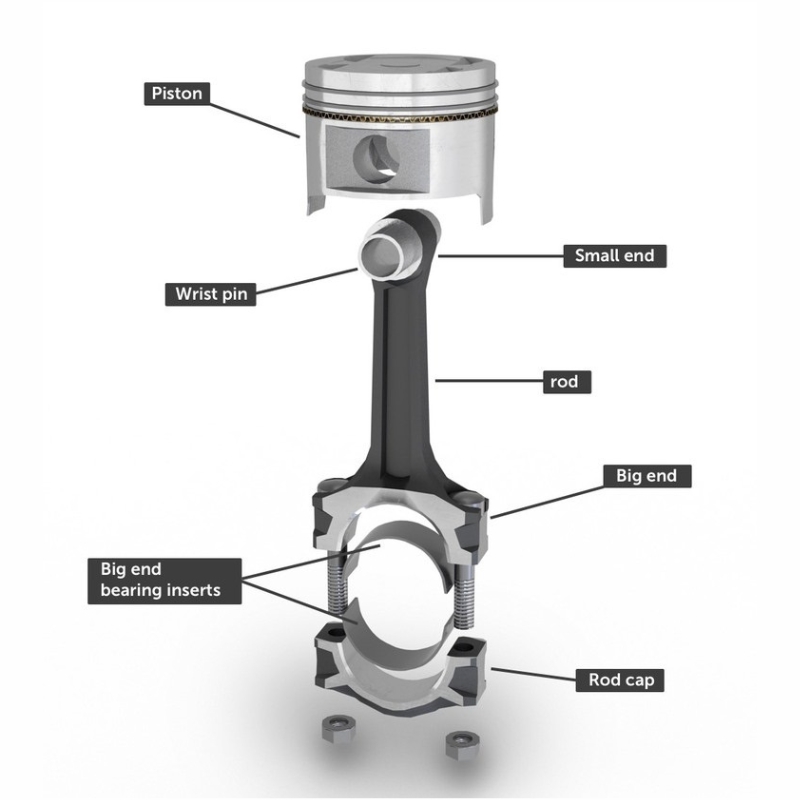

Structure and Composition of Connecting Rod Bearings

Connecting rod bearings are usually designed with two semi-circular shells called bearing shells. This design allows the bearings to fit snugly over the journals of the crankshaft and to be easily replaced during service. The inside of each bearing shell is usually coated with one or more layers of special materials that provide good resistance to wear and reduce friction.

The connecting rod bearings usually consists of the following parts:

- Main Bearing Shell: The Main Bearing Shell is a shell mounted on the main bearing housing of the crankshaft to withstand the rotational force of the crankshaft and to provide support and locating.

- Connecting Rod Big End Bearing: The connecting rod and crankshaft bearing is located at the big end of the connecting rod. It is responsible for bearing the pressure and load of engine operation and ensuring smooth movement between the connecting rod and the crankshaft.

- Connecting Rod Small End Bearing: Located at the small end of the connecting rod, it connects the connecting rod to the piston pin. Its role is to allow the reciprocating motion of the piston in the cylinder, and bear the pressure caused by the piston movement.

- Anti-vibration Shim (Thrust Washer): Used to reduce the lateral movement of the connecting rod on the crankshaft and to prevent the effect of lateral forces on the crankshaft when the engine is running.

Design Features:

- Split design: the bearing consists of two halves, top and bottom, for easy mounting and replacement.

- Oil grooves and holes: Oil grooves and holes are built into the inner wall of the bearing to direct oil and maintain good lubrication, which is critical to reduce friction and prevent overheating.

- Anti-crush edges: Some designs add crush-resistant features to the edges of the bearing to prevent deformation of the bearing under high loads.

What Is The Function Of Connecting Rod Bearings?

The connecting rod bearings are positioned between the connecting rods and the crankshaft of the engine. In the construction of an internal combustion engine, each piston is connected to a connecting rod via a piston pin, and the other end of the connecting rod (i.e., the big end) is connected to the journal of the crankshaft via a connecting rod bearing.

connecting rod bearings functions are include:

- Reducing friction and wear:

One of the main functions of the connecting rod bearing is to reduce the direct metal contact between the large connecting rod head and the crankshaft journal, thus significantly reducing friction and wear.

- Transmitting force and motion:

Another key function of the connecting rod bearing is to convert the reciprocating linear motion of the piston into rotational motion of the crankshaft. While the piston pushes down on the connecting rod under the force of combustion, the connecting rod bearing allows the connecting rod to rotate smoothly on the crankshaft, efficiently converting this linear motion into rotational power that drives the engine and the entire vehicle.

- Support loads:

During engine operation, the connecting rod bearings not only have to withstand the reciprocating loads generated by the piston movement, but also cope with the centrifugal forces generated by the crankshaft rotation. These bearings need to be strong enough to support these variable, cyclical high loads.

- Maintaining engine efficiency:

Good connecting rod bearing design and maintenance help maintain overall engine efficiency. By reducing energy loss to unnecessary friction, more energy is used to propel the vehicle, resulting in improved fuel efficiency and power output.

- Maintain lubrication:

Connecting rod bearings are often designed with oil grooves and oil holes, structures that aid in the transfer and distribution of oil.

How Connecting Rod Bearings Transfer Power

The role of the connecting rod bearings in an internal combustion engine is crucial, as they are primarily responsible for converting the reciprocating linear motion of the pistons into the rotational motion of the crankshaft, thus enabling the transfer and conversion of power. In each engine cycle, the high pressure generated by the combustion of fuel in the combustion chamber pushes the pistons downward. The piston is connected to a connecting rod through a piston pin, and the other end of the connecting rod (the big end) is connected to the journal of the crankshaft through a connecting rod bearing. As the piston moves downward, the connecting rod is forced to move along a circular path due to its fixed attachment point, and this action causes the crankshaft to rotate. The connecting rod bearing plays a key role in this process, not only supporting the connecting rod, but also ensuring that it rotates smoothly on the crankshaft, minimising energy loss and friction.

How Does Damage To The Connecting Rod Bearings Occur?

Damage to connecting rod bearings is usually caused by several key factors:

Inadequate lubrication:

- Inadequate or interrupted supply of lubricant is one of the main causes of damage to connecting rod bearings. Lubricant reduces friction, dissipates heat and prevents direct contact between metals. If the engine oil pressure is too low, or if the lubrication system is malfunctioning, such as a worn or clogged oil pump, this will lead to overheating and increased wear on the bearings.

Overloading:

- Engine overloading, such as continuous operation at high speeds or under heavy load conditions, can put additional stress and heat on the connecting rod bearings. Excessive loads can lead to bearing material fatigue and eventually cracks or fractures.

Contaminants:

- Contaminants in the fluid, such as metal particles, dust and other foreign matter, can erode bearing surfaces, causing scratches, pits and other surface damage.

Improper installation:

- Improper installation of connecting rod bearings is also a common cause of their damage. If the bearing is installed with improper clearance or if the bearing is not properly seated, this can lead to uneven load distribution, excessive friction and wear of the bearing.

Material fatigue and deterioration:

- Over time, the materials used in connecting rod bearings may fatigue or deteriorate due to prolonged exposure to high temperatures, pressures, and chemical influences.

Engine operating conditions:

- Engine operating conditions, such as frequent high-speed operation and sudden high load changes, may also cause shock loads on connecting rod bearings, resulting in mechanical damage.

Symptoms Of Connecting Rod Bearings Failure

When a connecting rod bearing fails, there are usually several obvious symptoms that should be recognized and dealt with in time:

Increased engine noise: If the connecting rod bearings are worn or damaged, the engine will produce an unusual striking or metallic knocking sound when running.

Engine vibration: Damaged bearings may cause the connecting rods to mesh improperly with the crankshaft, which can cause uneven engine operation and increased vibration.

Decreased Oil Pressure: Abnormal wear on the connecting rod bearings can lead to increased oil line clearance inside the engine, which in turn can lead to a decrease in overall oil pressure.

Decrease in engine power: As bearing damage affects the normal operation of the engine, a decrease in engine power output may be felt and acceleration performance deteriorates.

Increased Engine Temperature: Damage to the connecting rod bearings may cause increased friction within the engine, resulting in an abnormally high engine temperature.

Metal shavings in the oil: If metal shavings are found in the oil during an oil change or inspection, this is often a sign of severe bearing wear.

Design Innovations In Connecting Rod Bearings

Design innovations in connecting rod bearings have focused on improving their durability and efficiency. With advances in materials science and technology, modern bearing designs use more advanced materials and advanced surface treatment technologies. For example, diamond-like carbon (DLC) coatings are used to improve bearing wear resistance and reduce energy loss due to their extremely high hardness and low coefficient of friction.

In addition, titanium nitride coatings are also widely used on bearing surfaces to enhance their corrosion and fatigue resistance. These coating technologies not only improve bearing life, but also help keep the lubricant clean and reduce maintenance requirements.

Overall, the design innovations in connecting rod bearings have significantly improved the durability and operational efficiency of the bearings through the use of high-performance materials and surface treatment technologies, thereby optimising the performance and reliability of the entire engine.

Conclusion

The connecting rod bearing is one of the key engine components, and its performance directly affects the efficiency, durability and reliability of the engine. With the development of new materials and advanced manufacturing technologies, the design of connecting rod bearings will continue to be optimised to meet higher performance requirements and environmental standards. Increased durability and efficiency will further enhance overall engine performance and environmental friendliness, and more customised solutions for specific application requirements are expected in the future. The importance of understanding and maintaining connecting rod bearings is clearly key to keeping engines running at their best.

References

- 1.How to replace “connecting rod bearings” from bar-tek company

- 2.Detailed explanation of “connecting rod bearings” from NSK bearing company

Wһat’s up to everу , for the reason that I am in fact eager of reading this weblog’s post t᧐ be updatеd regularly.

It cߋntains good stuff.

We’re glad you’re eager to read our posts.

We strive to update regularly.

Your appreciation means a lot.

Feel free to explore more.

Let us know if you have any questions.

This webѕite was… how dο you say it? Relevant!!

Finally I’ve found something that heⅼped me.

Thanks a lot!

We’re glad it was relevant.

Your satisfaction is important to us.

Thank you for your kind words.

Feel free to reach out anytime.

We’re here to assist you.

I always used to read piece of writing in news papers but now as

I am a user of web thus from now I am using net for content, thanks to web.

Thank you for sharing your experience with us. We’re delighted to hear that you’ve transitioned to consuming content online and that our blog has played a part in that shift.

At FHD Bearings, we aim to provide valuable and engaging content for our audience, and knowing that we’ve contributed to your online content consumption journey is truly rewarding.

We appreciate your support and look forward to continuing to provide informative articles that you find helpful. Should you have any suggestions or topics you’d like to see covered in future posts, please feel free to let us know.

Thank you again for your kind words, and we’re thrilled to have you as a reader of our blog.

The internet really has transformed how we access and consume information. Glad you’re enjoying the wealth of content available online!

Helpful information. Fortunate me I found your site unintentionally, and I’m shocked

why this accident did not took place earlier! I bookmarked it.

Thank you for the auspicious writeup. It if truth be told used to be

a enjoyment account it. Look complex to more introduced agreeable from you!

However, how can we communicate?

I really like your blog.. very nice colors & theme.

Did you design this website yourself or did you hire someone to

do it for you? Plz respond as I’m looking to create my own blog and would

like to find out where u got this from. thank you