Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

What Are Crankshaft Bearings And Their Service Life

Introduction

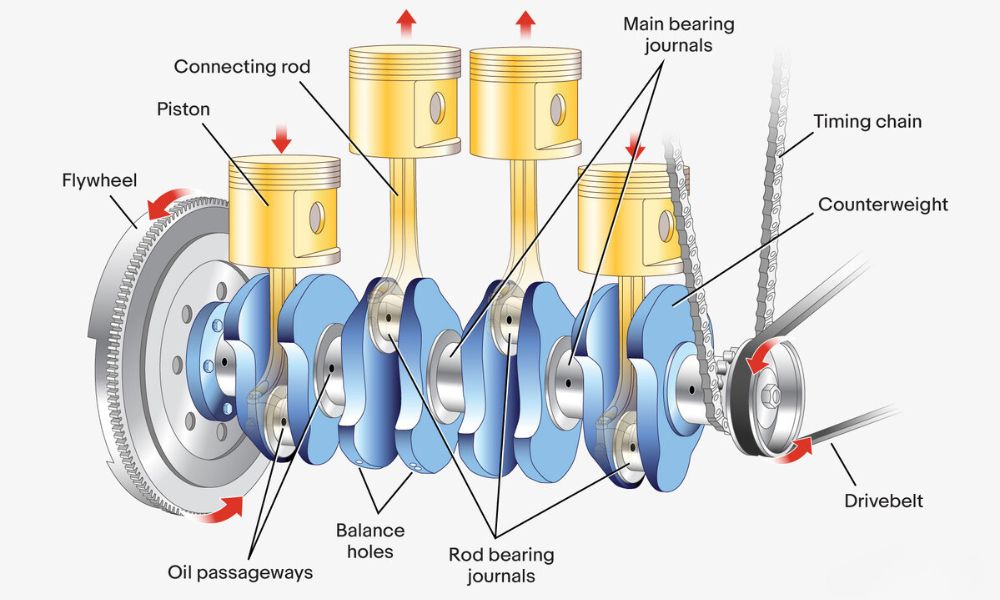

In the complex world of automotive engineering, each component plays a key role in ensuring optimal performance and longevity of the vehicle. Among these components, crankshaft bearings stand out as a key component that directly affects the operation and durability of the engine. Crankshaft bearings are a key component in an internal combustion engine that supports and allows the crankshaft to rotate smoothly. The crankshaft is responsible for converting the linear motion of the pistons into rotational motion, which ultimately drives the vehicle.

Crankshaft bearings are typically made of a durable material such as steel or aluminum, and are designed to withstand the high speeds and loads that are generated within the engine. They are placed at various points along the length of the crankshaft to provide support and reduce friction as the crankshaft rotates.

Structure Of Crankshaft Bearings

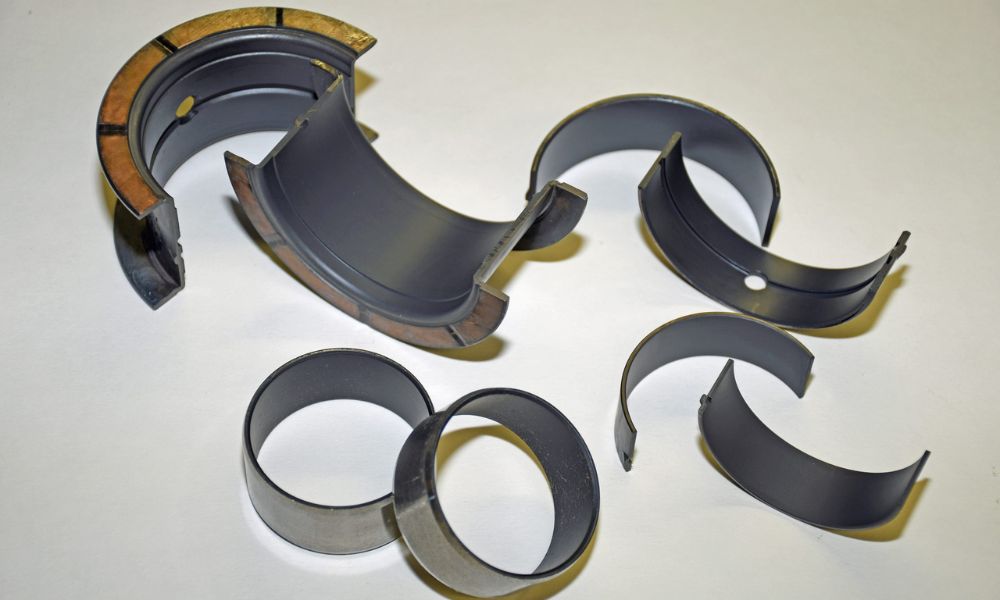

Crankshaft bearings are cylindrical components designed to support and facilitate the smooth rotation of the crankshaft within the engine block. Usually made of durable materials such as steel, bronze or aluminum alloys, these bearings consist of several layers:

- Support Layer: The foundation of the bearing, usually made of steel, provides structural support and stability.

- Intermediate Layer: This layer, usually composed of copper, aluminum or bimetallic materials, serves as the binder between the support layer and the cover layer.

- Covering Layer: The surface layer that is in direct contact with the crankshaft day shaft, usually consisting of a soft material such as lead, tin or an alloy. The cover layer reduces friction and wear between the crankshaft and the bearings.

Crankshaft Bearings Service Life

Crankshaft bearings are important components in internal combustion engines, which are subjected to the rotational forces of the crankshaft and operate at high speeds and high temperatures. The service life of crankshaft bearings depends on a variety of factors, including engine type, load, speed, lubrication and maintenance. Generally speaking, reasonable use and regular maintenance can prolong the service life of crankshaft bearings, which can usually reach 100,000 to 200,000 kilometers under normal working conditions.

However, the service life of crankshaft bearings may be greatly shortened if the engine is operated at high speeds for long periods of time, lacks regular maintenance, or uses poor-quality lubricants. In addition, poor driving habits such as frequent idling, rapid acceleration and hard braking can also accelerate the wear of crankshaft bearings.

In order to extend the life of the crankshaft bearings, it is recommended that the engine oil and oil filter be changed regularly, and to ensure that high quality lubricants that meet the specifications are used. In addition, it is very important to avoid idling and rapid acceleration and deceleration driving, and to regularly check the working condition of the engine and crankshaft bearings.

Extended Life Through Maintenance

To maximize crankshaft bearing life, companies should implement an aggressive maintenance strategy:

- Periodic Inspection: Periodically check bearings for signs of wear such as abnormal noise, vibration, or metal particles in the oil.

- Lubrication management: Use a high-quality lubricant suitable for specific operating conditions and adhere to recommended oil change intervals.

- Temperature Control: Maintains optimum operating temperature within the engine to prevent thermal expansion and minimize stress on the bearings.

- Filter Maintenance: Keep your oil filter clean and replace it regularly as recommended to prevent contaminants from circulating and damaging bearings.

- Alignment Checks: Regularly inspect and realign components to ensure proper alignment and minimize uneven loading on bearings.

Conclusion

In conclusion, the lifespan of a crankshaft bearing is an important factor in the overall performance and reliability of an engine. By using high-quality bearings, following proper maintenance practices, and operating the engine under the correct conditions, vehicle owners can help to ensure that their crankshaft bearings last for many thousands of miles. Regular inspections and maintenance can help to identify any issues with the bearings early on, allowing for repairs to be made before more serious damage occurs. By taking care of the crankshaft bearings, vehicle owners can help to ensure the long-term durability and reliability of their engine.

References

- 1.Detailed explanation of the “Crankshaft ” from Wikipedia;

- 2. More details about ”crankshaft bearings“ ;