Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

The Importance Of Properly Maintained Gas Turbine Bearings

Introduction To Gas Turbine Bearings

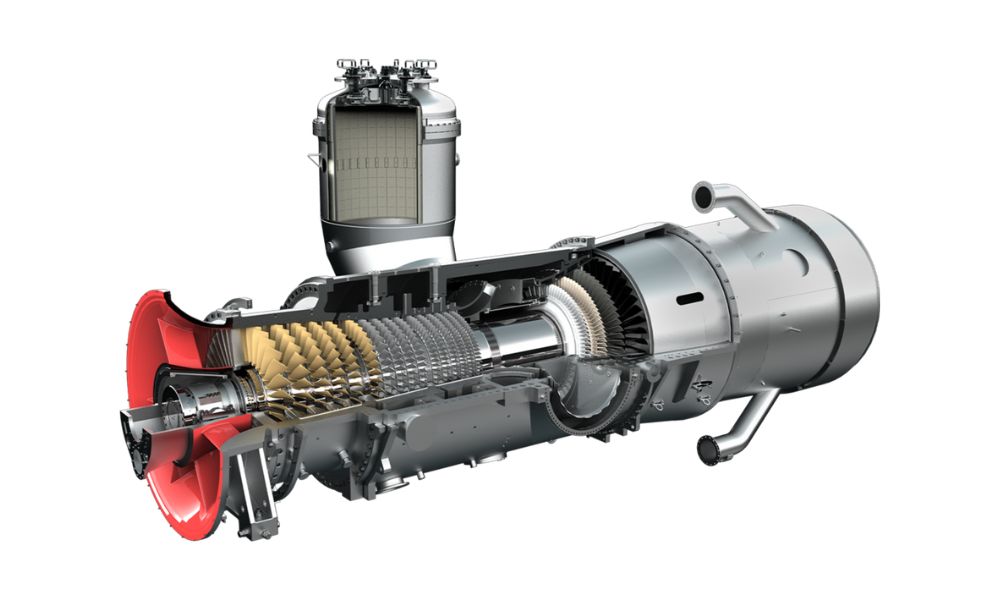

Gas turbine bearings are a critical component of gas turbine engines, playing a key role in supporting rotating parts and reducing friction. These bearings must be able to withstand high temperatures, heavy loads, and high speeds, making them a crucial element in the efficient operation of gas turbine engines.

Gas turbine bearings are mechanical components designed to support rotating shafts within the turbine. They serve several critical functions, including:

- Load Support: Gas turbine bearings bear the weight of the rotating components, ensuring smooth operation under varying loads.

- Alignment: Proper alignment of shafts is essential for minimizing friction and wear, thereby enhancing turbine efficiency.

- Vibration Dampening: Bearings help dampen vibrations caused by rotational forces, maintaining stability and reliability.

Selection Of Materials

Gas turbine bearing material selection critically affects bearing performance and life. Common gas turbine bearing materials include:

- Steel alloys: Good strength and wear resistance, suitable for general working conditions.

- Alumina ceramics (Alumina): excellent wear resistance and high temperature stability, suitable for high-speed bearings.

- Zirconia ceramics: Higher hardness and strength for higher loads and severe operating environments.

- Polytetrafluoroethylene (PTFE): Good self-lubrication and chemical stability to reduce friction and extend bearing life.

Gas Turbine Bearing Maintenance

Gas turbines are essential pieces of equipment in various industries, including power generation, aviation, and oil and gas. These machines rely on a complex system of components to function efficiently, with one critical element being the bearings. Gas turbine bearings play a crucial role in supporting the rotating shafts of the turbine, reducing friction, and ensuring smooth operation. Without properly maintained bearings, the performance and reliability of a gas turbine can be compromised.

One of the primary functions of gas turbine bearings is to support the weight of the rotating shafts and ensure they remain in alignment during operation. Bearings are subjected to high speeds, temperatures, and loads, making them susceptible to wear and damage over time. Regular maintenance and monitoring of gas turbine bearings are essential to prevent premature failure and costly downtime.

Proper lubrication is key to the longevity and efficiency of gas turbine bearings. Lubricants help reduce friction between the bearing surfaces, dissipate heat, and prevent corrosion. It is crucial to use the correct type and amount of lubricant, as well as adhere to the recommended maintenance schedule for lubrication. Failure to properly lubricate gas turbine bearings can lead to overheating, increased wear, and eventual failure.

In addition to lubrication, regular inspection and monitoring of gas turbine bearings are essential to detect early signs of wear or damage. Vibrations, unusual noises, or changes in operating temperatures can indicate a problem with the bearings and should be investigated promptly. Routine maintenance tasks, such as bearing inspections, alignment checks, and vibration analysis, can help identify issues before they escalate into major problems.

Replacing gas turbine bearings can be a costly and time-consuming process, making preventive maintenance crucial to extending the lifespan of the bearings and the overall turbine system. Proper storage and handling of spare bearings are also essential to ensure they are in optimal condition when needed for replacement. Working with a reputable supplier for bearings and lubricants can help ensure the quality and reliability of these critical components.

Conclusion

Gas turbine bearings are vital components that play a key role in the performance and reliability of gas turbine systems. Understanding bearing functions, types, maintenance requirements and technological advancements is critical to ensuring optimal operation and maximizing service life of your gas turbine system. By prioritizing proper maintenance and embracing technological advances, industries can realize increased efficiency, reduced downtime and improved profitability in gas turbine operations.

References

- 1.Some information about “gas turbine bearings” and seals

- 2.Additional information about “gas turbine bearings”