Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

What is jewel bearing

A jewel bearing is a type of bearing that uses hard, durable gems like sapphire, ruby, or diamond to reduce friction in precision instruments. These jewel bearings are typically found in mechanical watches, compasses, and other devices requiring low-friction, long-lasting support for rotating or oscillating components.

Key points about jewel bearings:

- Materials: Synthetic sapphire and ruby are most commonly used because they are hard, wear-resistant, and can be polished to a fine finish.

- Precision: They offer highly accurate movement and minimal wear, making them ideal for small, delicate applications.

- Types: The most common types are hole and cap jewel bearings. A hole jewel is used to support a shaft or pivot, while a cap jewel provides a surface for the pivot tip to rest on.

- Advantages: Jewel bearings are resistant to corrosion, operate with low friction, and have a long life, which makes them popular in devices where minimal maintenance is desired.

In a mechanical watch, for instance, jewel bearings reduce friction between the gear wheels and their pivots, thus improving accuracy and longevity.

Application and type of gemstone bearing

Applications of Jewel (Gemstone) Bearings:

Mechanical Watches:

- Jewel bearings are crucial in mechanical watches to reduce friction between moving parts like the gear train, escapement, and balance wheel pivots.

- They improve accuracy and longevity of the timepiece by minimizing wear on critical components.

Precision Instruments:

- Devices such as compasses, gyroscopes, and balancing instruments use jewel bearings for their stability and minimal friction, essential for accurate readings and reliable performance.

Aerospace and Defense:

- Jewel bearings are used in gyroscopic instruments and other sensitive devices in aircraft and defense equipment for precision guidance and navigation systems.

Medical Devices:

- Instruments like flow meters and microsurgical tools often use jewel bearings to ensure precision and durability in environments requiring exact measurements or delicate operations.

Electrical Meters and Gauges:

- Many analog ammeters, voltmeters, and other precise measuring devices employ jewel bearings to support moving pointers with minimal friction, resulting in smooth, accurate readings.

Relays and Switches:

- Jewel bearings can be found in small, sensitive electromechanical systems such as relays, where they provide low friction and long-lasting performance under frequent operation.

Types of Jewel Bearings:

Hole Jewel Bearings:

- These are the most common type, where the pivot of a shaft or arbor sits inside a small hole in the jewel. The jewel’s hard, polished surface minimizes wear and friction.

- Example: Used in the pivots of mechanical watches.

Cap Jewel Bearings:

- Cap jewels are flat disks placed over hole jewels or used as thrust bearings. They provide a surface for a pivot to rest on, reducing endplay and friction.

- Example: Often paired with hole jewels in watches for better axial positioning.

V-Jewel Bearings:

- These have a V-shaped groove that supports a shaft and offers two points of contact, commonly used for rotating shafts in electrical meters and gyroscopes.

Endstone Bearings:

- Flat jewels (endstones) used at the end of the pivot to prevent axial movement and limit friction, typically in precision applications.

- Example: Used in sensitive watches and gauges.

Roller Jewel:

- A small cylindrical or half-round jewel mounted on a shaft or roller, mainly used in the escapement mechanism of watches to control the release of energy.

Types of Gemstones Used in Bearings:

Ruby:

- Synthetic ruby (aluminum oxide) is one of the most common materials because of its hardness (9 on the Mohs scale), resistance to wear, and ability to be polished to a very fine finish.

- Example: Frequently used in watch movements.

Sapphire:

- Synthetic sapphire, chemically the same as ruby (but without the red color), is also used for its hardness and durability.

- Example: Used in optical devices and high-precision instruments.

Diamond:

- Diamond, being the hardest material known (10 on the Mohs scale), is used in ultra-precise applications where minimal friction and wear are essential.

- Example: Found in specialized high-end watches and scientific instruments.

Garnet:

- Less commonly used, but garnet bearings may appear in some specialized applications where its hardness and wear resistance are sufficient.

History and Evolution of Gemstone Bearings

1.1 Early Uses of Gemstone Bearings

Gemstone bearings have been in use for centuries, with their origins tracing back to early horology and the creation of accurate timepieces. Watchmakers quickly realized that traditional metal bearings wore out too quickly. The use of natural gems like sapphire improved the accuracy and lifespan of their products.

1.2 Key Innovations in Gemstone Bearing Technology

Innovations in synthetic gemstone production in the 20th century revolutionized the bearing industry. With the advent of synthetic rubies, manufacturers could produce high-quality, consistent bearings at a fraction of the cost of natural gems. Advances in precision manufacturing techniques also allowed for tighter tolerances and improved performance.

1.3 Current Trends in Gemstone Bearing Manufacturing

Today, gemstone bearing manufacturing focuses on sustainability and precision. The growing demand for eco-friendly production has led to the development of synthetic gemstones with minimal environmental impact. Additionally, innovations in laser cutting and polishing have made the production process more efficient, resulting in even higher-quality components.

Types of Gemstones Used in Bearings

2.1 Synthetic Ruby Bearings

Synthetic ruby is the most common material used in gemstone bearings due to its hardness and cost-effectiveness. It offers excellent resistance to wear and can be manufactured in precise shapes, making it ideal for high-precision instruments like watches.

2.2 Sapphire Bearings

Sapphire bearings are valued for their extreme hardness, second only to diamond. They are often used in high-end applications where both durability and optical clarity are required. Their resistance to scratching and wear makes them perfect for sensitive equipment such as gyroscopes.

2.3 Diamond Bearings

Diamond bearings are used in ultra-high-performance applications where maximum durability is needed. Their exceptional hardness allows them to operate under extreme conditions with minimal wear. They are often found in scientific instruments that require the utmost precision and longevity.

Key Properties of Gemstone Bearings

3.1 Hardness and Wear Resistance

The hardness of gemstones like ruby and sapphire is critical in reducing wear and tear over time. This allows the bearings to maintain their precision and functionality, even in environments with constant motion and friction. Their durability ensures a longer lifespan compared to metal bearings.

3.2 Low Friction and Smooth Operation

Gemstone bearings are designed to reduce friction between moving parts, enabling smooth and efficient operation. This is essential in devices like watches, where even slight resistance can affect timing accuracy. Their low-friction nature also reduces heat buildup, preventing damage to delicate components.

3.3 Chemical and Thermal Stability

One of the standout features of gemstone bearings is their resistance to chemical reactions and temperature extremes. Whether in hot, cold, or corrosive environments, they maintain their structural integrity, ensuring consistent performance. This makes them ideal for aerospace and industrial applications where conditions can be harsh.

How Gemstone Bearings Enhance Performance

4.1 Reducing Friction for Smooth Movement

By minimizing contact friction between moving parts, gemstone bearings ensure smoother operation and less energy loss. This translates into more efficient performance and reduced mechanical strain on other components, especially in high-speed or high-precision environments.

4.2 Extending Lifespan of Precision Instruments

Gemstone bearings significantly extend the life of devices by reducing wear on pivots and shafts. Instruments like high-precision watches and measuring tools benefit from this, as the bearings can function optimally for decades without needing replacement, lowering maintenance costs over time.

4.3 Improving Accuracy and Consistency

In devices that rely on accurate measurements or timekeeping, the use of gemstone bearings ensures consistent performance. Their ability to operate with minimal friction and wear keeps the mechanism stable, resulting in improved accuracy and a higher-quality final product.

Industries That Benefit from Gemstone Bearings

5.1 Watchmaking and Horology

The watchmaking industry heavily relies on gemstone bearings to ensure smooth, precise movement within mechanical watches. The longevity and low maintenance of these bearings make them ideal for high-end, luxury timepieces that require reliability over decades.

5.2 Aerospace and Defense Applications

Aerospace and defense sectors use gemstone bearings in sensitive instruments like gyroscopes and navigation systems. Their ability to function in extreme environments, combined with their precision, makes them indispensable for mission-critical applications.

5.3 Medical Devices and Equipment

In medical devices, precision and reliability are paramount. Gemstone bearings are used in surgical tools, diagnostic equipment, and other high-performance medical devices, where they provide smooth operation, reducing wear and ensuring consistent functionality in critical applications.

Applications of Gemstone Bearings in Precision Instruments

6.1 Gyroscopes and Compasses

In gyroscopes and compasses, gemstone bearings allow for frictionless rotation, ensuring that the instrument provides accurate and consistent directional information. These bearings help maintain stability and precision in devices subject to movement or varying gravitational forces.

6.2 Analog Meters and Gauges

Gemstone bearings are also crucial in analog meters and gauges, where precise needle movement is required for accurate readings. By reducing friction in the moving parts, these bearings enhance the accuracy and responsiveness of these devices, even in demanding industrial environments.

6.3 Scientific and Measuring Devices

In scientific equipment, where accuracy can be critical to the outcome of experiments or measurements, gemstone bearings provide the reliability needed for repeatable results. Their smooth operation helps prevent drift in sensitive instruments, making them invaluable in laboratory settings.

The Manufacturing Process of Gemstone Bearings

7.1 Gemstone Sourcing and Selection

The first step in manufacturing gemstone bearings involves sourcing high-quality synthetic gemstones, such as ruby or sapphire. Manufacturers choose these materials based on specific hardness, durability, and resistance to wear. Proper selection ensures that the final bearings meet industry standards for longevity and precision.

7.2 Cutting and Shaping Techniques

Advanced cutting and shaping techniques, often involving lasers or diamond tools, are used to carve the gemstones into the desired form. The process requires extreme precision to achieve the tight tolerances required for bearing applications. Accurate shaping ensures smooth movement and minimal friction in the final product.

7.3 Polishing and Finishing

After shaping, the gemstone bearings are meticulously polished to reduce surface roughness. Polishing is crucial in ensuring that the bearing surface is smooth, which directly affects its performance by reducing friction and wear. High-quality finishes result in improved durability and operational efficiency.

The Role of Gemstone Bearings in Reducing Maintenance

8.1 Minimizing Wear and Tear

Gemstone bearings drastically reduce wear and tear on moving parts by offering a harder, more durable surface compared to metal alternatives. This leads to less degradation over time, extending the lifespan of the components they support. For procurement professionals, this means fewer replacements and repairs.

8.2 Reducing Need for Lubrication

Due to their low friction properties, gemstone bearings often require less lubrication than traditional metal bearings. This reduces the frequency of maintenance cycles and lowers the risk of lubricant contamination in precision instruments. The result is more reliable operation over time with less upkeep.

8.3 Long-Term Cost Savings

Although gemstone bearings may have a higher initial cost, their ability to reduce wear and maintenance leads to significant long-term savings. These bearings lower operational costs by minimizing downtime and extending the life of equipment, making them a cost-effective investment for procurement professionals.

Comparison: Gemstone Bearings vs. Traditional Bearings

9.1 Durability and Wear Resistance

Compared to traditional metal or ceramic bearings, gemstone bearings offer superior durability and wear resistance. The hardness of synthetic gemstones like ruby ensures that they can withstand high levels of friction and wear over time, reducing the frequency of replacements.

9.2 Friction and Efficiency

Gemstone bearings provide lower friction compared to traditional bearings, which enhances the efficiency of the devices they are used in. Lower friction leads to smoother movement, less energy consumption, and improved performance, especially in high-precision or high-speed applications.

9.3 Cost and Value for Money

While gemstone bearings typically come at a higher price point than metal bearings, their long-term benefits justify the investment. Their durability, low maintenance needs, and extended lifespan offer greater value over time, particularly in industries where precision and reliability are essential.

In summary, jewel bearings, particularly those made of synthetic ruby and sapphire, are essential in precision engineering due to their durability, low friction, and wear resistance across various fields like horology, aerospace, and medical devices.

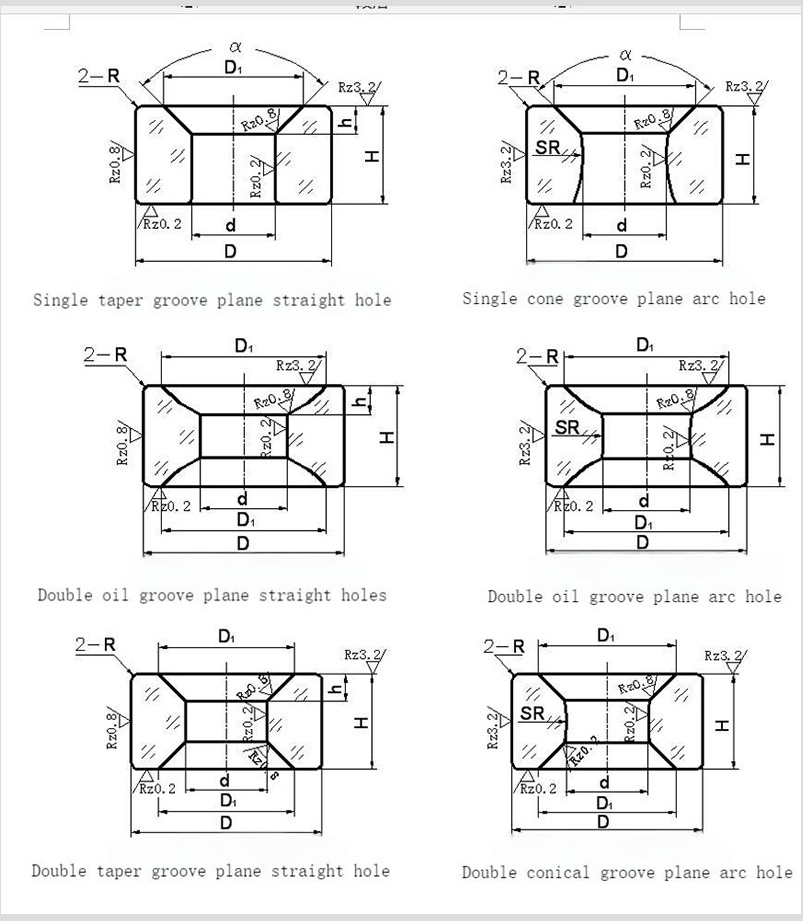

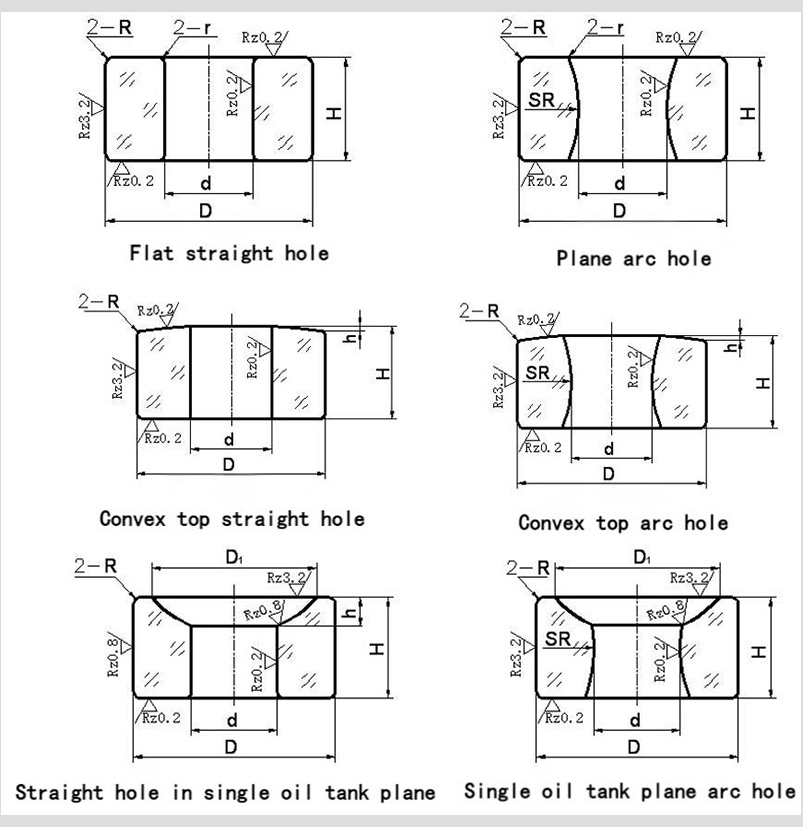

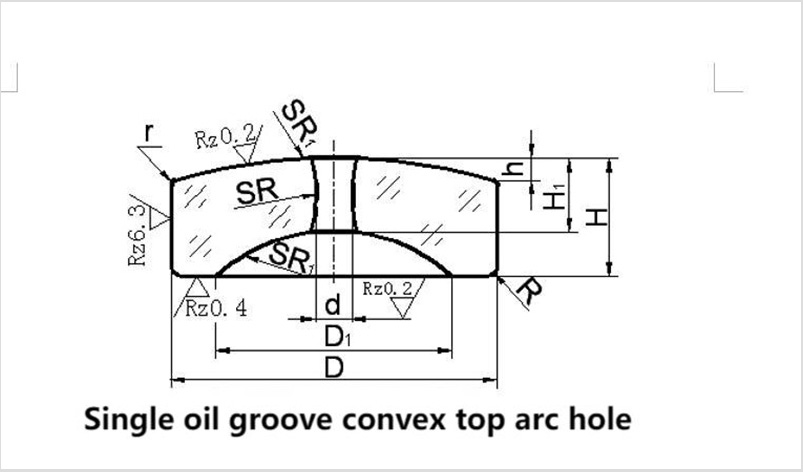

Gemstone bearing diagram

Thank you for sharing with us, I conceive this website genuinely stands out : D.