Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Understanding the Mechanics of Hydrodynamic Bearings

Introduction

Hydrodynamic bearings play a crucial role in various industrial applications, providing support, reducing friction, and enhancing the longevity of machinery components. In this blog post, we will delve into the intricacies of hydrodynamic bearings, exploring their definition, significance in industrial applications, and providing an overview of the blog’s analysis.

Definition and Purpose

Hydrodynamic bearings are mechanical devices designed to support and facilitate the movement of rotating shafts within machinery. Unlike traditional bearings that rely on rolling elements, hydrodynamic bearings operate on the principle of a thin film of fluid, usually oil, creating a lubricating layer between the rotating shaft and the bearing surface. This fluid film prevents direct metal-to-metal contact, reducing friction and wear, thus enhancing the lifespan and efficiency of the machinery. Commonly used in large industrial applications such as turbines, engines, and generators, hydrodynamic bearings offer benefits like improved load-carrying capacity, damping of vibrations, and enhanced stability, making them crucial components in ensuring the smooth operation of various mechanical systems.

Significance in Industrial Applications

Hydrodynamic bearings play a crucial role in numerous industrial applications, contributing significantly to machinery efficiency and reliability. In heavy-duty settings such as power generation, hydrodynamic bearings support rotating shafts in turbines and generators, reducing friction and wear to optimize performance and extend equipment lifespan. In large-scale manufacturing processes, these bearings find application in various machinery, from pumps to compressors, ensuring smoother operation and minimizing maintenance needs. Their ability to handle heavy loads and absorb vibrations makes them indispensable in precision machinery, like machine tools, where stability and accuracy are paramount. The industrial significance of hydrodynamic bearings lies in their capacity to enhance overall equipment performance, reduce downtime, and ultimately contribute to the economic and operational success of diverse sectors.

Fundamentals of Hydrodynamic Bearings

Working Principle and Basic Components

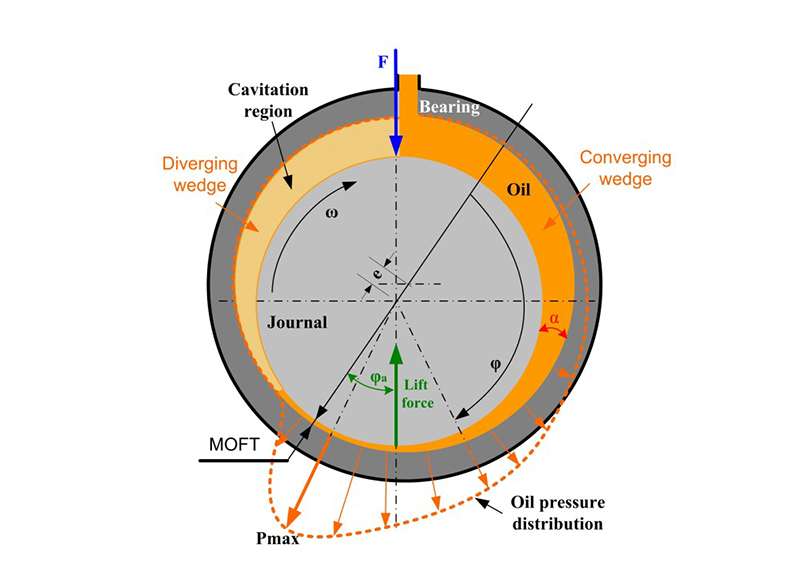

Hydrodynamic bearings operate on a sophisticated yet effective principle to support rotating shafts within machinery. The basic composition typically includes a bearing surface and a rotating shaft, where the key element is the thin film of lubricating fluid, commonly oil. This fluid film is created dynamically as the shaft rotates, generating a wedge-shaped layer that lifts and separates the shaft from the bearing surface.

The rotating motion of the shaft induces a pressure gradient in the lubricant, forming a thicker fluid layer between the two surfaces. This separation eliminates direct metal-to-metal contact, reducing friction and wear. The lubricating fluid not only serves as a protective barrier but also carries away heat generated during operation, contributing to the cooling of the system.

The effectiveness of hydrodynamic bearings is rooted in their ability to adapt to varying loads and speeds, providing reliable support and facilitating smooth rotation across a spectrum of industrial applications. This dynamic and self-sustaining lubrication mechanism enhances overall machinery performance, reduces maintenance requirements, and ensures the longevity of equipment in diverse industrial settings.

Types of Hydrodynamic Bearings

Journal Bearings: Also known as sleeve bearings, these bearings support the rotating shaft on a thin layer of lubricating fluid, creating a film between the shaft and the bearing surface.

Thrust Bearings: Specifically designed to handle axial loads, thrust bearings use fluid film lubrication to separate moving components in the axial direction, ensuring smooth operation under heavy loads.

Tilting-Pad Bearings: These bearings consist of multiple pads arranged in a circular pattern. Each pad tilts independently, adjusting to changing loads and providing stability in various operating conditions.

Fixed Geometry Bearings: Unlike tilting-pad bearings, fixed geometry bearings have a stationary geometry. They are often used in applications where a consistent load and operating condition are expected.

Elliptical Bearings: These bearings utilize an elliptical shape for the journal and bearing surfaces, creating a more stable lubricating film. They are commonly employed in high-speed rotating machinery to achieve enhanced stability and load-carrying capacity.

Fluid Dynamics in Hydrodynamic Bearings

Fluid Film Thickness and Pressure Distribution

In the hydrodynamics of hydrodynamic bearings, the liquid film thickness and pressure distribution play pivotal roles. As the shaft rotates within the bearing, it induces a pressure gradient in the lubricating fluid, leading to the creation of a thin liquid film between the shaft and the bearing surface. This film is dynamic and wedge-shaped, becoming thicker towards the outlet due to the rotational movement. The pressure distribution within this lubricating film is non-uniform, with higher pressures at the center and lower pressures towards the edges. The maximum pressure occurs near the point where the shaft exits the bearing. The variation in pressure and liquid film thickness is crucial for load support, preventing metal-to-metal contact, reducing friction, and ensuring optimal performance of the bearing. Engineers carefully analyze and optimize these factors to design hydrodynamic bearings that effectively support loads, minimize wear, and enhance the overall efficiency of rotating machinery.

Shear Forces and Viscosity Effects

The hydrodynamics of hydrodynamic bearings involve shear and viscosity effects that significantly influence their performance. Shear effects occur as the lubricating fluid experiences deformation between the rotating shaft and the stationary bearing surface. This shear induces forces within the fluid, contributing to the formation and maintenance of the lubricating film. The viscosity of the lubricant, a measure of its resistance to deformation, is a crucial factor influencing shear effects. Higher viscosity fluids create thicker lubricating films, enhancing load-carrying capacity but potentially increasing fluid friction. Conversely, lower viscosity fluids may reduce friction but could compromise load support. Engineers carefully select lubricants with appropriate viscosity to strike a balance between load capacity and friction losses. Understanding and manipulating these shear and viscosity effects are essential in optimizing the design and performance of hydrodynamic bearings, ensuring efficient load support, reduced wear, and overall enhanced reliability in various industrial applications.

Lubrication Systems in Hydrodynamic Bearings

Role of Lubricants in Bearing Operation

Lubricants play a critical role in the operation of hydrodynamic bearings, ensuring smooth functionality and minimizing wear. Typically, oils are the preferred lubricants due to their ability to form a protective film between the rotating shaft and the bearing surface. This lubricating film prevents direct metal-to-metal contact, reducing friction and dissipating heat generated during operation. The lubrication cycle employs various methods to maintain an optimal supply of lubricant. Splash lubrication relies on the natural splashing motion of the rotating shaft to distribute oil, while forced lubrication involves an external pump actively circulating lubricant to the bearing surfaces. Proper lubrication is essential for maximizing the load-carrying capacity, minimizing friction, and promoting the overall efficiency and longevity of hydrodynamic bearings in diverse industrial applications.

Lubricant Flow Patterns and Control Mechanisms

Lubricant flow patterns and control mechanisms are integral aspects of hydrodynamic bearings, influencing their efficiency and performance. In operation, the rotating shaft induces a dynamic pressure in the lubricant, forming a wedge-shaped film. The lubricant flow pattern is typically characterized by an inward flow towards the center, creating a thicker film at the region where the shaft exits the bearing. Control mechanisms are employed to optimize this flow pattern and ensure uniform lubricant distribution. Variable eccentricity, achieved through design adjustments or tilting-pad configurations, allows for adaptive control of the lubricant film thickness based on varying loads and speeds. Additionally, external pumps or hydrostatic systems actively regulate lubricant supply to maintain the desired pressure and film thickness. This control over lubricant flow patterns is crucial for achieving optimal load support, reducing friction, and enhancing the overall effectiveness of hydrodynamic bearings in diverse industrial applications.

Performance Characteristics of Hydrodynamic Bearings

Load-Carrying Capacity: Hydrodynamic bearings excel in supporting heavy loads, providing a robust foundation for rotating machinery across various industrial applications.

Friction Reduction: The dynamic fluid film created by hydrodynamic bearings effectively reduces friction between the rotating shaft and the bearing surface, minimizing wear and energy losses.

Vibration Damping: Hydrodynamic bearings contribute to the damping of vibrations, enhancing the stability and smooth operation of machinery by absorbing and dissipating vibrations generated during operation.

Heat Dissipation: Efficient heat dissipation is a key performance characteristic. Hydrodynamic bearings help dissipate heat generated during operation, preventing overheating and ensuring optimal operating temperatures.

Adaptability to Changing Conditions: These bearings exhibit adaptability to varying loads and speeds, thanks to their dynamic lubrication mechanism. This adaptability is crucial for maintaining performance under different operational scenarios.

Longevity and Reliability: Hydrodynamic bearings contribute to the longevity and reliability of machinery by minimizing wear, reducing maintenance requirements, and providing consistent performance over extended periods of operation.

Friction and Wear Reduction Strategies

Optimal Lubricant Selection: Choosing the right lubricant with appropriate viscosity and additives is crucial for reducing friction and wear. Proper lubricants create an effective film between the rotating shaft and the bearing surface, minimizing direct metal-to-metal contact.

Surface Finish and Quality: Ensuring high-quality surface finishes on both the rotating shaft and bearing surfaces promotes smoother interaction and reduces friction. Precise machining and polishing techniques contribute to improved performance.

Precision Alignment: Accurate alignment of the hydrodynamic bearing components is essential. Misalignment can lead to uneven loading, increased friction, and accelerated wear. Precision alignment enhances the effectiveness of the lubricating film.

Balanced Load Distribution: Proper design and load distribution within the hydrodynamic bearing prevent localized pressure points and uneven wear. Strategies such as tilting-pad configurations contribute to more uniform loading.

Cooling Systems: Implementing effective cooling systems, such as forced lubrication or cooling fins, helps dissipate heat generated during operation. Controlled temperatures prevent thermal degradation of lubricants and reduce wear.

Regular Maintenance and Monitoring: Implementing a proactive maintenance schedule and monitoring system allows for timely detection of issues and wear. Regular inspections, lubricant analysis, and component checks contribute to the prevention of excessive friction and wear in hydrodynamic bearings.

Real-World Applications of Hydrodynamic Bearings

Turbines: Fluid dynamic bearings are widely used in various types of turbines, such as steam turbines and gas turbines, where they support the rotating shafts and provide smooth operation under high-speed and high-temperature conditions.

Compressors: In industrial applications like air compressors, fluid dynamic bearings help support the rotating elements, ensuring efficient and reliable compression processes by minimizing friction and wear.

Electric Motors: Fluid dynamic bearings find applications in electric motors, where they support the rotor shaft. This usage contributes to energy efficiency and reduced maintenance needs in electric motor-driven systems.

Machine Tools: Precision machine tools, including lathes and milling machines, often incorporate fluid dynamic bearings to achieve stable and precise motion, ensuring accurate machining processes.

Pumps: Fluid dynamic bearings play a crucial role in pumps by supporting the rotating shaft, reducing friction, and enhancing the overall efficiency of fluid transfer in applications ranging from water pumps to industrial process pumps.

Generators: Hydrodynamic bearings are commonly employed in generators, supporting the rotating components and ensuring smooth rotation to generate electrical power efficiently.

Conclusion

In conclusion, hydrodynamic bearings stand as indispensable components in diverse industrial applications, offering enhanced machinery efficiency, reduced friction, and prolonged equipment lifespan. Their dynamic fluid film lubrication mechanism, adaptability to varying conditions, and significant load-carrying capacity make them vital for the optimal performance of turbines, compressors, electric motors, machine tools, pumps, and generators. Through careful consideration of fluid dynamics, lubrication systems, and performance characteristics, engineers can harness the benefits of hydrodynamic bearings, contributing to the economic success and operational reliability of industries worldwide.

References

- 1.”Basics of Hydrodynamic Bearings in Industrial Applications” from Pumps & Systems;

- 2. “Hydrodynamic Bearing – an overview” from ScienceDirect.com;

- 3. “Hydrodynamic Bearings” from Waukesha Bearings.