Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (27)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

How Do Linear Bearings Work?

Introduction To Linear Bearings

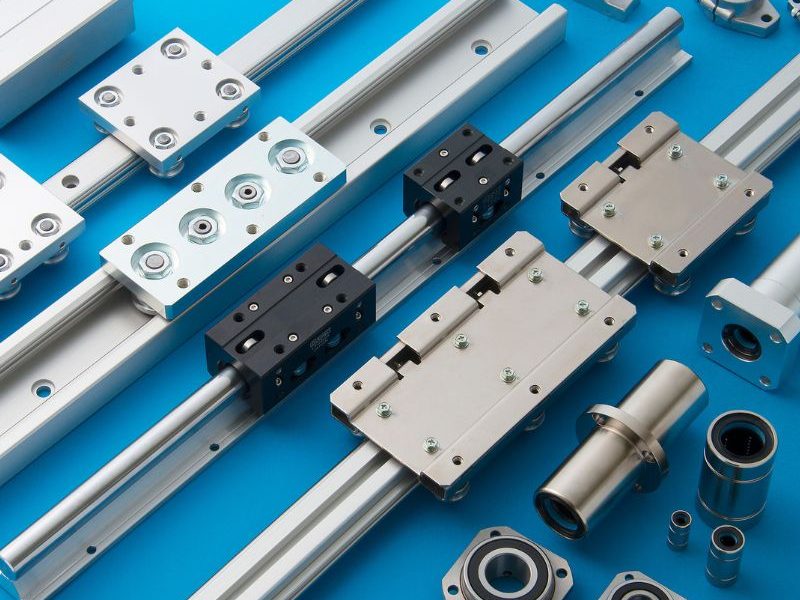

Linear bearings are mechanical components designed to facilitate linear motion, converting rotational motion into linear motion with minimal friction. They consist of an outer housing and an inner carriage or ball mechanism that moves along a linear track. By providing support and guidance to moving parts, linear bearings enable smooth and precise motion in machinery and equipment.

Linear Bearings slide on a Linear Axis in a straight line. Because they are a bearing it allows you to move a significant amount of weight in a linear motion with great ease. The Linear Bearing takes all the weight without restricting the linear motion of the object, hence the name.

Linear Bearing slide rails provide accurate, stable, and smooth linear guidance under a wide range of speeds, loads, conditions and space requirements. Linear Bearings are used in applications that require linear motion of heavy weights in a repeatable motion.

Types Of Linear Bearings

- Linear Ball Bearings: These bearings utilize balls to reduce friction and enable smooth linear motion. They are commonly used in applications requiring high precision and moderate load capacity.

- Linear Roller Bearings: Unlike ball bearings, roller bearings use cylindrical rollers to support the load. They offer higher load capacity and are suitable for applications with heavier loads or harsh operating conditions.

- Plain Bearings: Also known as bushings, plain bearings use sliding surfaces instead of rolling elements. They are preferred for applications where simplicity, low cost, and resistance to contamination are crucial.

- Linear Air Bearings: Air bearings use a thin film of pressurized air to support the load, resulting in ultra-smooth and frictionless motion. They are ideal for high-speed and precision applications such as semiconductor manufacturing and metrology.

How Do Linear Bearings Work?

The working principle of linear bearings is based on reducing friction between moving parts, resulting in smooth and efficient linear motion. Understanding how they work is critical to the correct selection and use of linear bearings.

- 1. Rolling elements and sliding surfaces

Linear bearings can be divided into two categories: rolling bearings and sliding bearings. Rolling bearings (such as ball bearings and roller bearings) reduce friction through rolling elements (balls or rollers). When a load is applied to the bearings, the rolling elements roll on the track, resulting in smooth motion. In contrast, sliding bearings (such as sliding bushing bearings) use lubricant between sliding surfaces to reduce friction and achieve linear motion.

- 2. Internal vehicle and external track

Linear bearings usually consist of an inner carrier and an outer track. Internal carriers (such as balls or balls) are in direct contact with the rolling elements or sliding surfaces and are responsible for carrying the load. The outer track provides a platform that guides and supports the inner vehicles, ensuring they move along a predetermined straight path.

- 3. Minimum friction design

Effective linear bearing designs are designed to minimize friction to ensure smooth motion and efficient energy transfer. By optimizing the materials, surface finish and lubricant selection of rolling elements or sliding surfaces, friction losses can be reduced, bearing efficiency can be improved, and service life can be extended.

- 4. Precision positioning and alignment

The working principle of linear bearings also involves precision positioning and alignment. As the inner vehicles move along the outer track, they maintain precise alignment with the track, ensuring accurate position control and smooth motion. This precision is critical for applications requiring high-precision positioning and motion control, such as CNC machine tools and precision measurement equipment.

- 5. Wear resistance and durability

Finally, the working principle of linear bearings is also closely related to their wear resistance and durability. By choosing the right materials and lubrication methods, and implementing appropriate maintenance measures, you can extend the service life of your bearings and reduce the frequency of repairs, thereby reducing overall operating costs.

Applications Of Linear Bearings

Linear bearings are used in a wide range of applications across various industries. Some common applications include:

- CNC Machines: Linear bearings are used in CNC machines to provide precise linear motion for cutting and milling operations.

- Robotics: Linear bearings are used in robotic arms and actuators to provide smooth and accurate motion.

- Packaging Machinery: Linear bearings are used in packaging machinery to move products along conveyor belts.

- Medical Devices: Linear bearings are used in medical devices such as surgical robots and imaging equipment for precise positioning.

- 3D Printers: Linear bearings are used in 3D printers to move the print head along the X, Y, and Z axes for accurate printing.

Conclusion

The key when selecting the appropriate linear bearing is to consider load capacity, speed, accuracy, environmental conditions and maintenance needs. It is necessary to ensure that the bearings can withstand various loads and adapt to high-speed motion and precision positioning requirements, while withstanding the effects of different working environments, and have minimum maintenance requirements to ensure the reliability and long-term operation of the equipment.

Overall, linear bearings play a crucial role in ensuring smooth and precise motion in a wide range of mechanical systems. By reducing friction and providing support and guidance for moving loads, linear bearings help improve efficiency, accuracy, and reliability in various applications. Whether in industrial machinery, automation systems, or consumer electronics, linear bearings are essential for ensuring smooth and efficient operation.

References

- 1.Something about “linear bearings” from Bearings company

- 2. Detailed introduction to ”linear bearings“ from wikipedia;