What are Magnetic Bearings

Table of Contents

Definition

Magnetic bearings use magnetic fields to levitate an object, allowing for frictionless rotational and axial movement. Unlike traditional bearings, which require physical contact and lubrication, magnetic bearings eliminate wear and friction. This technology is critical in high-performance settings like aerospace and energy generation, where low friction and high efficiency are essential. The result is increased lifespan, reduced maintenance, and enhanced energy efficiency, revolutionizing conventional mechanical design paradigms.

Introduction

Understanding the nuances of magnetic bearings is not just an exercise in academic curiosity; it serves as a cornerstone for optimizing industrial applications. Delving into the mechanics and benefits of this unique technology unveils its unparalleled capabilities and potential for transformative impact.

The Basics of Magnetic Bearings

What are Magnetic Bearings?

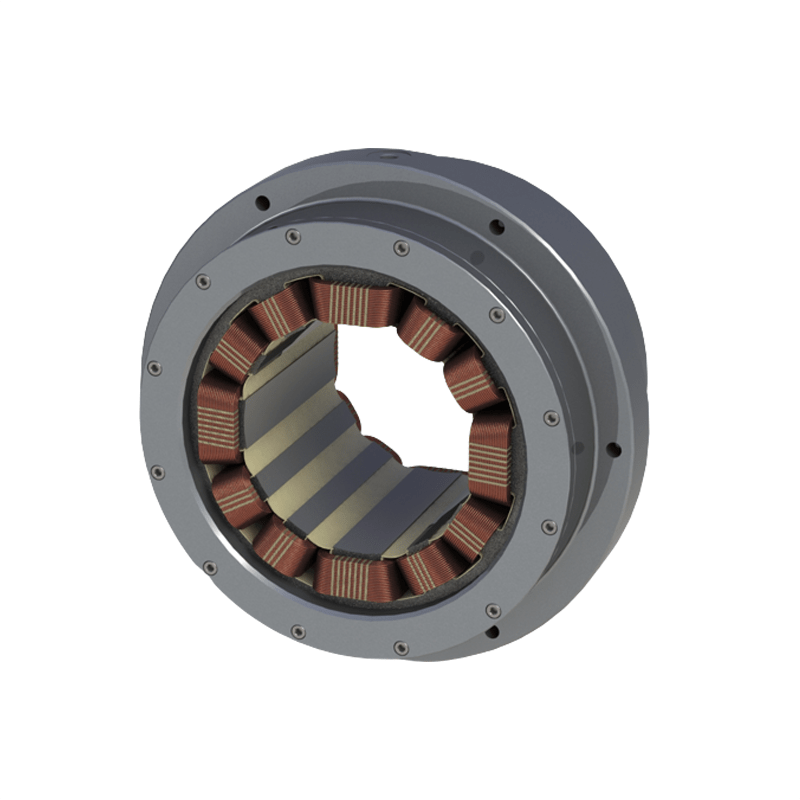

Magnetic bearings are essentially mechanical bearings that leverage magnetic levitation to attain an almost frictionless state, circumventing direct contact between moving parts.

How do Magnetic Bearings Work?

Utilizing electromagnetic coils and magnetic fields, magnetic bearings suspend a rotor in a magnetic field, thereby mitigating the effects of friction and wear. This enables smooth, high-speed operations.

Advantages of Magnetic Bearings Over Traditional Bearings

Their salient features include negligible friction, high rotational speeds, and extended operational longevity, rendering them a viable alternative to their traditional counterparts.

Types of Magnetic Bearings

Active Magnetic Bearings

Active magnetic bearings are automated systems that utilize sensors and feedback loops to adjust magnetic fields dynamically, ensuring optimal balance and stability.

Passive Magnetic Bearings

Contrarily, passive magnetic bearings utilize permanent magnets and are devoid of control systems, relying purely on inherent magnetic repulsion or attraction.

Hybrid Magnetic Bearings

A synergistic blend of both active and passive components, hybrid magnetic bearings harness the best of both realms, aiming for both stability and energy efficiency.

Applications of Magnetic Bearings

Industrial Machinery

From turbo machinery to compressors, magnetic bearings have carved a niche in reducing wear and tear and improving performance metrics.

High-speed Trains and Transportation

With their capability for high-speed operation devoid of friction, they are an ideal fit for next-generation transportation systems.

Aerospace and Aviation

The aerospace sector greatly benefits from the reduced weight and high-speed capabilities, aiding in fuel efficiency and overall performance.

Energy Generation

In wind turbines and other energy generation systems, magnetic bearings enhance reliability and operational longevity.

Magnetic Bearings vs. Traditional Bearings

A Comparative Analysis of Performance

Traditional bearings often excel in systems with high radial loads or those requiring rugged mechanical designs. Magnetic bearings, on the other hand, excel in high-speed, low-to-medium load applications where friction and wear are primary concerns. Each has its own realm of superiority, and the optimal choice is highly dependent on the specific operational criteria at hand.

Cost-Effectiveness in the Long Run

While the initial investment in magnetic bearings is higher, the reduction in maintenance costs, coupled with increased operational efficiency, can result in a favorable total cost of ownership over the system’s lifecycle. Such an economic evaluation necessitates a nuanced understanding of both direct and indirect cost factors, from parts replacement and downtime to energy consumption.

Specific Use Cases for Each Type of Bearing

Heavy-duty industrial applications, such as in mining or construction, may still favor traditional bearings for their mechanical robustness. Conversely, high-speed rotors, precision medical devices, or energy-efficient HVAC systems represent ideal candidates for the adoption of magnetic bearings.

Advantages of Magnetic Bearings

Reduced Friction and Wear

In a traditional mechanical bearing system, the friction generated between the contacting surfaces is a primary cause of wear and tear. Magnetic bearings, by leveraging the principles of magnetic levitation, effectively eliminate the direct mechanical contact and therefore drastically curtail friction. This reduction leads to an enhancement in the lifespan of the system, facilitating long-term cost savings in maintenance and parts replacement.

Increased Efficiency

Less friction doesn’t merely extend the operational lifespan; it also substantially reduces energy consumption. This feature is particularly salient in an era where energy-efficient systems are not just preferable but increasingly mandated. For industries where energy costs comprise a significant portion of operational expenditure, such as in large-scale manufacturing or data centers, this advantage cannot be overstated.

Enhanced Reliability and Maintenance

In a frictionless environment, the typical mechanical stresses—resulting from thermal expansions or misalignments—are notably diminished. This improved state of affairs directly translates into fewer breakdowns and less unplanned maintenance. The result is a bearing system that is not only more reliable but also easier and less expensive to maintain over the long run.

Noise Reduction

In applications where noise levels are a concern—think medical equipment or residential HVAC systems—the absence of mechanical friction in magnetic bearings substantially reduces operational noise. This is an often-overlooked but vital advantage, especially in environments requiring stringent noise controls.

Future Trends in Magnetic Bearings

Emerging Technologies and Innovations

The rise of smart technologies like the Internet of Things (IoT) is poised to bring about a new era in magnetic bearing capabilities. With real-time monitoring and analytics, future magnetic bearing systems will be more adaptive and capable of self-optimization, enhancing both performance and reliability.

Potential Advancements in Magnetic Bearing Applications

The proliferation of renewable energy solutions presents an intriguing avenue for magnetic bearings, especially in wind turbines and hydroelectric generators. Their increased efficiency and reduced maintenance could be the catalysts that drive broader adoption of sustainable energy technologies.

Impact on Various Industries

As magnetic bearing technology matures, its reach is extending beyond the niche sectors where it originated. From automotive applications to home appliances, the promise of reduced energy consumption and lower maintenance costs has piqued interest across a wide array of industries.

By providing an expansive and nuanced perspective on magnetic bearings, this article aims to be a comprehensive resource for professionals in the field. The technology’s potential to redefine conventional wisdom about mechanical design and energy efficiency is enormous. As more industries begin to grasp the transformative potential of magnetic bearings, their adoption is likely to soar, marking a significant milestone in the journey towards more sustainable and efficient mechanical systems.

Conclusion

The odyssey through the realm of magnetic bearings elucidates their transformative potential. With continued advancements, these frictionless wonders stand poised to redefine multiple industrial landscapes. Embarking on this technological journey not only holds promise for operational excellence but also heralds a new era of sustainable industrial practices.