Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

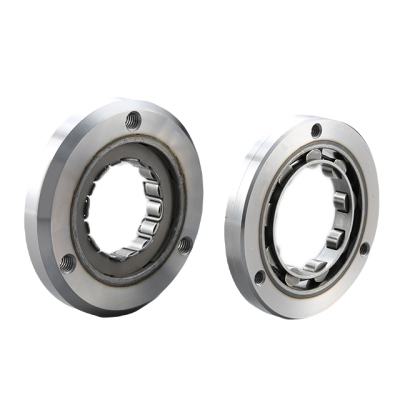

Introduction to One-Way Clutch Bearings

What Are One-Way Clutch Bearings?

One-way clutch bearings, also known as overrunning clutches or sprag clutches, are integral components in machinery requiring controlled motion in one direction. Used in various industrial applications, these bearings can significantly reduce wear and prevent reverse motion under load. This guide walks you through the correct installation steps for one-way clutch bearings, from initial inspection to secure testing, while highlighting common pitfalls to avoid.

Step 1: Inspect Bearing Components

Before starting the installation, carefully inspect the bearing and its components:

- Verify Condition: Look for any visible damage, scratches, or deformities on the bearing. Defects can impede the clutch function.

- Check Part Numbers and Specifications: Confirm that the bearing matches your equipment’s specifications, as incorrect bearings can lead to compatibility issues.

- Examine Packaging for Additional Components: Some clutch bearings come with supplementary parts, like washers or spacers. Ensure you have all required items.

A thorough initial inspection saves time and effort, minimizing risks of misalignment or mechanical malfunction.

Step 2: Verify Fit and Tolerances

Accurate tolerances are essential for optimal bearing performance. Here’s what to do:

- Measure the Shaft and Housing: Use micrometers or calipers to measure the shaft diameter and housing bore. Confirm that they fall within the manufacturer’s specified tolerance limits.

- Check the Bearing Clearance: Bearings typically require minimal clearance between the inner and outer components to function properly. Ensure the fit is not too tight, which may restrict movement, or too loose, which can lead to misalignment.

Any discrepancies in fit or tolerance can lead to bearing failure, excessive wear, or even machine damage over time.

Step 3: Prepare Shaft and Housing

Preparation of the shaft and housing is key to a stable, long-lasting bearing installation:

- Clean Surfaces Thoroughly: Remove any dirt, dust, or oil residue from the shaft and housing. Even minor debris can interfere with the bearing’s ability to engage smoothly.

- Check for Any Damage or Irregularities: Look for burrs, scratches, or other imperfections that could affect bearing placement. Smooth out irregularities with fine sandpaper if necessary.

- Apply a Light Coat of Lubricant (If Recommended): Some applications may call for light pre-lubrication. Follow the manufacturer’s guidance regarding any pre-assembly lubricants.

This preparation step helps ensure that the bearing fits correctly and operates smoothly.

Step 4: Insert the Bearing

Now it’s time to place the bearing within the shaft and housing:

- Align the Bearing with the Shaft: Gently position the bearing on the shaft, ensuring that it’s correctly oriented according to the desired direction of rotation.

- Use a Bearing Press or Arbor Press: Avoid hammering or forcing the bearing into position. If necessary, use a press tool to evenly distribute pressure and seat the bearing without damaging it.

- Double-Check Orientation: Confirm that the bearing is facing the correct direction before final seating, as one-way bearings only engage in one rotation direction.

Proper insertion is critical to preventing bearing misalignment or early wear.

Step 5: Apply Proper Lubrication

Lubrication is essential for bearing performance, particularly for one-way clutch bearings:

- Use the Correct Lubricant: Select a lubricant compatible with your specific bearing and application. Most clutch bearings require either light oil or grease.

- Apply the Lubricant Evenly: Avoid over-lubricating, as excess lubricant can attract debris and lead to contamination.

- Follow the Manufacturer’s Maintenance Schedule: Many bearings require periodic re-lubrication for consistent performance.

Correct lubrication minimizes friction, reduces wear, and maximizes the lifespan of the bearing.

Step 6: Secure and Test Bearing

With the bearing inserted and lubricated, the next step is securing and testing it:

- Secure the Bearing in Place: Depending on your equipment, use retaining clips or set screws to lock the bearing in position. Avoid overtightening, as this could impede the bearing’s movement.

- Rotate to Check Engagement: Manually rotate the bearing to verify smooth rotation in one direction and firm locking in the opposite.

- Perform a Functional Test on the Equipment: Once installed, run the machine at low speed to observe the bearing under light load. This step ensures that the bearing engages properly and aligns as expected.

Testing ensures that the bearing is secure and ready for operational use.

Common Mistakes to Avoid

Ensuring a successful installation of one-way clutch bearings requires careful attention to detail. Here are the common pitfalls that can jeopardize performance, cause early wear, or even lead to system failure.

1. Incorrect Orientation

One of the most frequent mistakes in installing one-way clutch bearings is incorrect orientation. These bearings are designed to lock in one direction and rotate freely in the opposite. Installing them in the wrong orientation prevents them from performing their primary function, often leading to operational issues or complete failure. Solution: Always check the manufacturer’s specifications and diagrams before installation, and confirm the direction of rotation aligns with your application requirements.

2. Improper Fit or Clearance

Precision fit and proper clearance are essential for bearing function. Ignoring the tolerance limits or fitting bearings too loosely or tightly can lead to:

- Excessive Wear: Tight fits can restrict bearing movement, generating excess friction and heat, accelerating wear.

- Premature Failure: Loose fits may cause the bearing to slip or misalign, leading to uneven stress and potential damage.

Solution: Use precision tools to measure the shaft and housing, ensuring they meet the recommended tolerances for optimal fit. This reduces unnecessary movement and extends bearing life.

3. Neglecting Lubrication

Lubrication is crucial for the proper functioning of one-way clutch bearings. Insufficient lubrication results in excess friction, causing high heat buildup, which can degrade the bearing’s materials. Over time, this leads to binding, premature wear, or even bearing seizure. Solution: Consult the manufacturer’s guidelines on the appropriate lubricant type and application frequency. Always apply a controlled amount, avoiding over-lubrication, which can attract debris and compromise bearing performance.

4. Using Improper Tools

Using incorrect tools during installation, such as hammers or makeshift pressing methods, is a common error that can damage both the bearing and housing. Forceful installation methods can lead to:

- Physical Damage: Hitting the bearing directly may cause dents, deformation, or cracking in the bearing or housing.

- Misalignment: Uneven pressure during installation can misalign the bearing, impairing its performance and leading to premature wear.

Solution: Use a bearing press or arbor press to evenly and securely install the bearing without damaging the components. Avoid any tools that could exert uneven or excessive force on the bearing.

5. Skipping Inspection of Components

Skipping a thorough inspection of components before installation is often a hidden culprit in failed bearing installations. Overlooking burrs, scratches, or other surface imperfections in the shaft or housing can disrupt the installation process or lead to bearing misalignment. Solution: Always clean and inspect both the shaft and housing before installing the bearing, removing any irregularities that could hinder a smooth installation.

10 FAQs About One-Way Clutch Bearings Installation

1. What Are One-Way Clutch Bearings?

A: One-way clutch bearings allow rotation in only one direction, effectively preventing reverse rotation. They are commonly used in applications where controlled directional motion is needed, such as conveyor systems, indexing devices, and automotive transmissions.

2. What Are the Most Common Applications for One-Way Clutch Bearings?

A: These bearings are widely used in automotive transmissions, conveyor systems, industrial machinery, and even in electric bikes. They control rotational movement and prevent reverse rotation, contributing to improved efficiency and durability.

3. How Should I Orient the Bearing During Installation?

A: The orientation of the one-way clutch bearing is critical. Install the bearing so that it rotates freely in the intended direction and locks when rotated in the opposite direction. Double-check orientation as installing it backward will prevent it from functioning correctly.

4. What Tolerances Are Required for the Shaft and Housing?

A: Tolerances vary by bearing model and application. It’s essential to adhere to the manufacturer’s specified tolerance limits for both the shaft and housing. Incorrect tolerances can lead to loose or overly tight fits, causing wear, misalignment, or operational failure.

5. Can I Use Any Lubricant for One-Way Clutch Bearings?

A: No, using the wrong lubricant can compromise the clutch mechanism. Always use the lubricant type recommended by the bearing manufacturer, as it will be tailored to the bearing’s material and operational requirements. The wrong lubricant can interfere with clutch performance or cause early wear.

6. What If the Bearing Feels Loose During Installation?

A: If the bearing feels loose, it’s possible the shaft or housing dimensions are out of tolerance. Re-measure both components to confirm they fall within specified limits. If problems persist, consult with the bearing manufacturer to determine if any corrective measures are necessary.

7. Is Pre-Lubrication Required Before Installation?

A: Some one-way clutch bearings require pre-lubrication before installation. Check the manufacturer’s guidelines, as pre-lubrication ensures smooth initial operation and helps prevent damage during the break-in period. However, over-lubrication should be avoided, as it can attract dust and debris.

8. What Tools Are Recommended for Installing One-Way Clutch Bearings?

A: A bearing press or arbor press is recommended for installing these bearings. Avoid using hammers or other tools that might exert uneven force, as this can damage the bearing and lead to misalignment. Proper tools help ensure a smooth and even installation.

9. How Do I Test the Bearing After Installation?

A: After securing the bearing, perform a manual rotation test to confirm it spins freely in the intended direction and locks in the opposite direction. Running the equipment at a low load also helps verify proper function and alignment.

10. What Are Common Mistakes to Avoid During Installation?

A: Common mistakes include incorrect orientation, ignoring tolerance requirements, neglecting lubrication, and using improper tools. These errors can result in premature wear or operational failure. To avoid issues, follow each step carefully and consult the manufacturer’s guidelines as needed.