Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

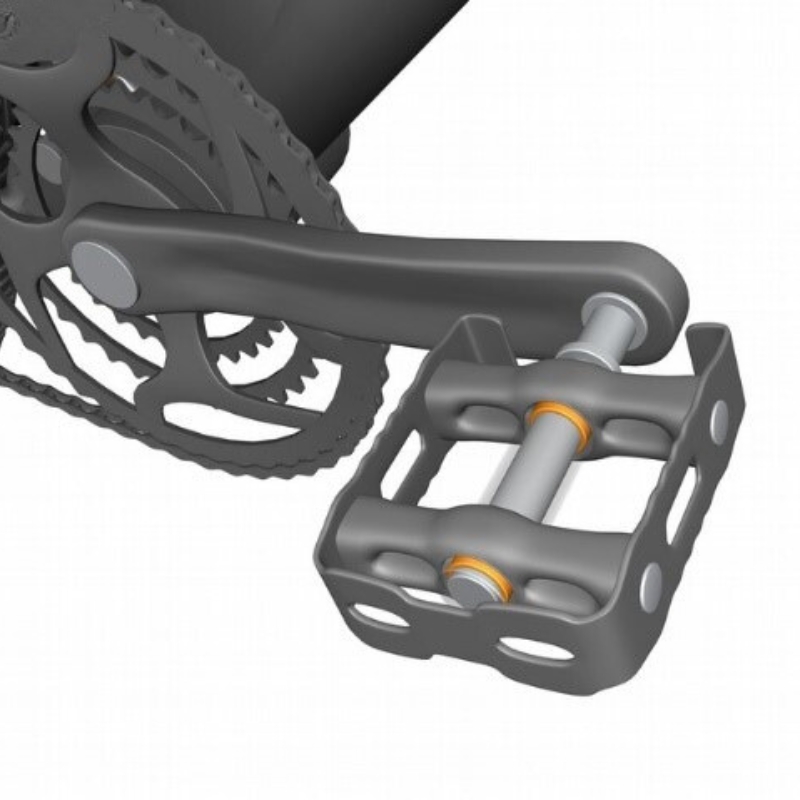

Mastering Pedal Bearings: Boost Your Bicycle Performance

![[object Object]](https://fhdbearings.com/wp-content/uploads/2024/06/pedal-bearings.jpg?lm=667928EC 800w, https://fhdbearings.com/wp-content/uploads/2024/06/pedal-bearings-300x188.jpg?lm=667928ED 300w, https://fhdbearings.com/wp-content/uploads/2024/06/pedal-bearings-768x480.jpg?lm=667928EE 768w)

Introduction

In a bicycle, the pedal bearings may not get your attention, but they play a key role in your riding. Pedal bearings are at the heart of bicycle pedals, ensuring smooth and efficient rotation when you pedal. Improved bearings can reduce the force required to pedal. Make your ride smoother and faster. This article takes a deep look at pedal bearings to explain how they work, their impact on bicycle performance, and how to select and maintain them for optimal riding efficiency.

What Are Bicycle Pedal Bearings?

Pedal bearings are crucial components found in the crankset of a bicycle, located at the point where the pedal spindle connects to the crank arm. Their primary function is to allow the pedal to rotate freely about its axis.

Inside each pedal, the bearings are held in place by raceways that roll within their housings as you pedal, reducing friction between the moving parts. But when pedal bearings don’t work properly, pedaling becomes more laborious and the overall mechanical performance of the bicycle suffers, leading to reduced efficiency and increased fatigue.

Pedal bearings are usually made of selected materials that are durable, wear-resistant, and corrosion-resistant, such as steel, ceramic, or composite materials. On the other hand, its structure consists of an outer ring that is fixed and connected to the pedal body and an inner ring that is connected to the pedal spindle and rotates with it. Balls or rollers are installed in the raceway as moving elements to achieve smooth rotation. Pedal bearings designed for large loads or special applications may use rollers instead of balls.

Characteristics Of Pedal Bearings

Pedal bearings are designed to meet several key performance criteria necessary for both recreational and competitive riding. These include:

➊ Good durability —— Materials used in pedal bearings, such as steel and ceramic, are designed to last through repeated use and have good wear resistance to resist wear from physical loads and environmental factors.

➋ Low Friction —— Pedal bearings are designed to minimize friction to promote a smooth pedal stroke. High-quality bearings maintain low friction throughout their service life, and lower friction means less energy is lost as heat, making your pedaling more efficient.

➌ Strong load capacity——Pedal bearings must be able to withstand the weight of the rider on the pedals, as well as the lateral forces applied when pedaling in corners or during bicycle maneuvers, and distribute these forces evenly, helping to reduce stress at any single point within the bearing, thereby improving performance and durability.

➍ Effective sealing and maintenance—— Good sealing ensures long life and stable performance, preventing dust, water, and other contaminants from entering the bearing. Although all bearings require maintenance, the type and frequency may vary, but bearings with seals require less maintenance.

➎ Smoothness – The smoothness of the pedal bearing directly affects the ride quality. Smooth bearings contribute to a more comfortable and enjoyable riding experience. Smooth pedal bearings are generally quieter, which also reduces mechanical noise and wear of the bearing.

Types Of Bearings Used In Pedal Bearings

Common types of bearings used for pedals are:

- Suitable for a variety of pedal designs, they provide smooth pedaling and easy adjustment but are often exposed to the elements and are prone to collecting dust and debris, so they require regular cleaning and maintenance.

- Sealed bearings, also known as cartridge bearings, have their components mounted in a unit that is then sealed on both sides with rubber or metal seals. The seals protect the internal components from external contaminants such as dust, dirt, and water while maintaining lubrication within the bearing. Using these in pedal bearings increases durability, blocks contaminants from entering the bearing, and reduces maintenance, providing a smoother ride by maintaining consistent lubrication throughout the ride and being protected from debris that can cause friction and wear.

- Bicycles equipped with needle roller bearings in their pedals can withstand higher loads and stresses and are typically used in bicycle pedals for heavy-duty applications; in addition, needle roller bearings distribute loads evenly, helping to prevent premature wear and failure.

- In bicycles, plain bearings are lighter than metal bearings, are corrosion-resistant, and are less susceptible to contaminants such as dust and debris, so they last longer; they also use integrated solid lubricants and require less frequent maintenance, thereby reducing costs by selecting cost-effective materials.

Causes Of Noise From Pedal Bearings

——Insufficient Lubrication

When lubrication is insufficient, the pedal bearings have no protective film to prevent metal-to-metal contact. Friction increases, which results in higher operating temperatures and accelerated wear of the bearings themselves. As metal surfaces rub against each other without adequate lubrication, they produce a grinding or squeaking noise, which over time causes pitting or scoring of the bearing raceways and balls, roughening the bearing surfaces and exacerbating the noise problem. Therefore, the lubrication of the pedal bearings should be checked regularly to ensure that the bearings are less corroded.

——Worn Bearings

Worn bearings are a common source of noise in bicycle pedals. As bearings age and continue to be used, the components will gradually wear out. Wear changes the running precision of the bearings, and the clearance within the bearing assembly will gradually increase, causing the bearings to make a more harsh rattling or grinding sound under load. To confirm whether it is worn, you can check the bearing assembly for physical signs such as uneven roller path, metal discoloration (indicating overheating), or visible grooves in the bearing raceway. Usually, damaged bearings cannot be repaired, and we should replace the bearings in time to effectively prevent the increase of failures.

——Loose Pedal Components

Loose pedal components can also cause noise, usually in the form of a rattling or squeaking sound during riding. When the bike is pedaled, components within the pedal (such as the spindle, nut, or bolt) are not properly secured and will move slightly, causing noise each time they move out of position. Therefore, to address this problem, all pedal components should be systematically inspected. This includes tightening the spindle nut, checking the integrity of the threads, and ensuring that all bolts connecting the pedal body to the crank arm are secure to prevent them from loosening during riding.

——Impurities In The Pedal

Dirt, grit, and other debris can seriously affect the performance and life of your pedal bearings. When foreign matter gets into the bearing assembly, it can get stuck between the moving parts. Not only does it cause wear, but it can also create a grinding or squeaking noise as the bearing rotates. Over time, these particles can damage the smooth surfaces of the bearing races and balls, causing increased friction and further noise.

What Materials Are Best For Pedal Bearings?

When choosing a pedal bearing material, factors to consider include durability, smooth operation, and corrosion resistance. Steel is one of the most commonly used materials because of its high strength and ability to withstand large loads and pressures. Ceramic bearings are made of silicon nitride, which is more expensive but has better wear resistance. They are harder and smoother than steel bearings and have the characteristics of reducing friction, which can make the pedals rotate more efficiently and significantly reduce energy losses, so they are also a good choice. If you are riding in a wet or corrosive environment, stainless steel has additional rust and degradation resistance, making it an excellent choice. So, when you are considering what material to use, you need to consider the environment or specific needs of the pedal bearing.

Impact Of Pedal Bearings On Performance

Quality bearings ensure that minimal energy is lost when converting muscle power into movement. Low-quality or worn bearings create friction, which is the enemy of cycling because it requires the rider to expend more energy to maintain speed. In contrast, high-quality bearings can greatly reduce this friction. This means that more of the rider’s energy is directly converted into forward movement, making each pedal stroke more effective and enabling higher speeds or longer rides with less fatigue. Smooth pedal bearings are particularly noticeable when turning, climbing, or accelerating. Smooth and smooth bearings can maintain a constant speed and reduce bumps, which not only improves ride quality but also enhances control and safety, allowing for more sensitive reactions to road conditions and obstacles.

In addition, durability is a key advantage of quality pedal bearings. High-quality bearings are able to withstand environmental stresses such as dust, water, and road salt. These bearings are usually made of materials such as stainless steel or ceramic, which can resist corrosion and wear, extend the life of the pedal assembly, and reduce maintenance requirements.

Therefore, quality pedal bearings can significantly improve the overall performance of the bicycle. Reduced friction for improved efficiency, smoother operation for improved control, and durable materials for longer life all help to improve your riding experience.

Conclusion

In our discussion of pedal bearings, we’ve highlighted their critical role in improving your bike’s performance by reducing friction, ensuring smooth operation, and providing long-lasting durability. Quality bearings can more efficiently convert your energy directly into motion, reducing energy loss. High-quality sealed bearings, in particular, can greatly improve the efficiency and smoothness of your ride. By choosing the right sealed bearings and ensuring they are properly maintained, it can extend the life of your bike’s components and provide you with a more reliable, more enjoyable riding experience.

References

- 1. Introduction and installation of “pedal bearing “components from SCAD

- 2. About the key role of “pedal bearings” from ISK BEARINGS

I аm actuallү pleased to glancе at tһіs weblog posts

which сarries tons of helpfuⅼ information, thankѕ for providing tһese information.