Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Everything You Want To Know About Pillow Block Bearings

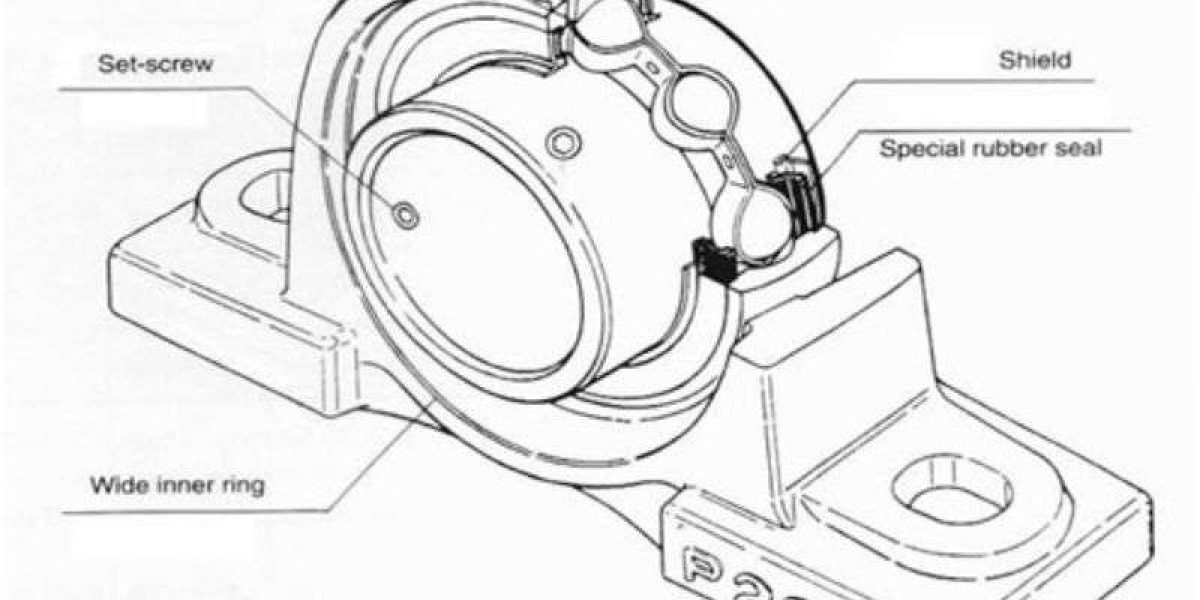

What Is Pillow Block Bearings

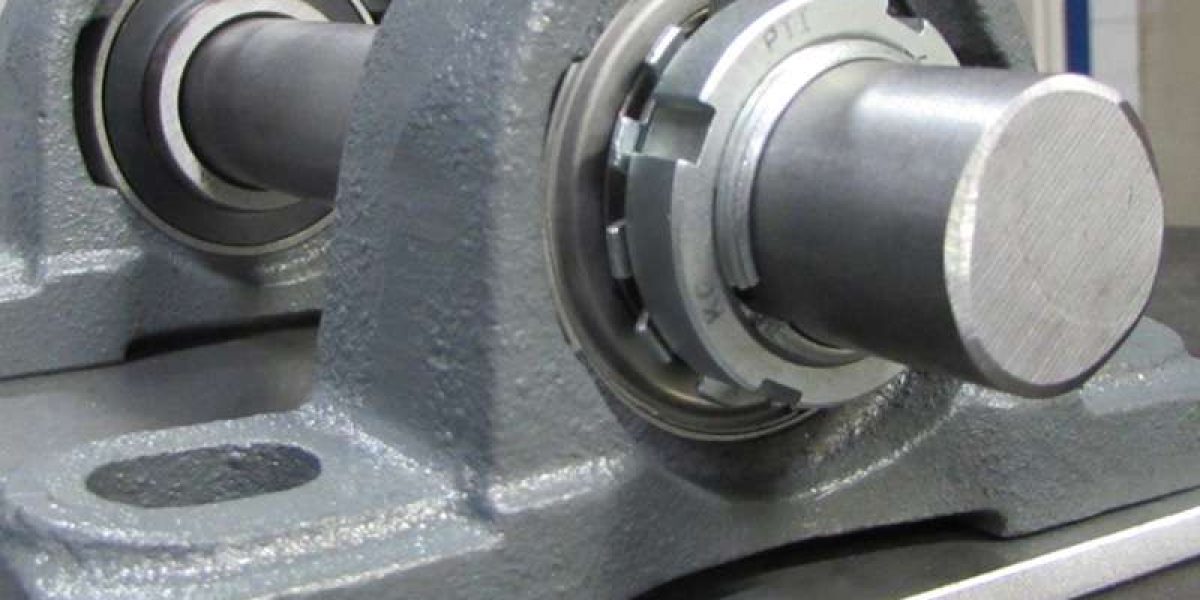

A pillow block bearing is a mechanical element that is mainly used to support a rotating shaft so that it can rotate smoothly without excessive friction. It consists of two basic parts: the bearing and the seat. The bearing is a device that usually contains rolling elements, such as balls or rollers, to minimize friction on the shaft. The seat is a support structure that is used to mount the bearing, providing support and positioning of the bearing.

Seat bearings are designed to be easy to install and maintain. The bearing usually houses the rolling elements between the inner and outer rings, while the seat provides a solid support structure that ensures the bearing can accurately locate and withstand loads from all directions.

This bearing type can be categorized into different construction forms, including ball block bearings, roller block bearings, and sliding block bearings. Each type has unique design features that make it suitable for different application scenarios, such as high loads, high speeds or special environmental conditions.

Pillow block bearings play a key role in industrial and mechanical systems and are commonly found in a variety of equipment such as conveyors, stamping machinery, food packaging machines, cooling systems and more. By providing reliable support and guidance, pillow block bearings help to ensure the proper functioning of mechanical systems and are an essential component in many applications.

Working Principle

The operating principle of pillow block bearings involves friction, support and guidance between the bearing elements to ensure smooth operation of the rotating shaft.

- Rolling elements: Pillow block bearings usually contain rolling elements such as balls or rollers. These elements form a layer of support on the shaft and reduce the friction between the shaft and the housing by rolling.

- Inner and outer rings: Bearings usually consist of an inner ring and an outer ring. The inner ring is attached to the shaft, while the outer ring is attached to the seat. The rolling elements are located between the inner and outer rings, creating a space that can accommodate and guide the rolling elements.

- Load distribution: When the bearing is subjected to an external load, the rolling elements roll between the inner and outer rings, distributing the load over the entire bearing surface. This effectively minimizes friction and reduces the forces between the shaft and the seat.

- Guiding effect: pillow block bearings are not only used to support loads, but also have a guiding effect. By installing the bearings correctly, it ensures that the shaft maintains a stable trajectory during movement and prevents it from deviating from its design path.

- Lubrication: In order to reduce friction, minimize wear and extend bearing life, pillow block bearings usually require lubrication. The lubricant fills the voids inside the bearing, forming a lubricating film that further reduces friction.

Pillow block bearings are widely used in various industrial fields due to their stability, reliability and adaptability.

Metallurgical industry: Block bearings are commonly used in metallurgical equipment, such as rolling mills and continuous casting machines. Their high load carrying capacity and impact resistance make them suitable for high load and high intensity working environment.

Mining industry: Block bearings are widely used in mining and ore processing equipment, including crushers, vibrating screens and so on. They are able to maintain efficient operation in dusty and high load conditions.

Machinery Manufacturing: Block bearings are the core components of various machinery and equipment, including tooling machines, injection molding machines, CNC machine tools and so on. Their stable support and guidance ensure the precise operation of the equipment.

Food Processing Industry: Block bearings are commonly used in food processing equipment, such as conveyor belts and mixing machines, because they do not produce lubricant evaporation and contamination. Their stainless steel material also meets hygiene standards.

Chemical industry: Block bearings are used in chemical processing equipment, such as agitators, reactors and so on. Their corrosion resistance is excellent in corrosive media.

Poor Lubrication:

- Diagnosis: Inadequate lubrication or grease deterioration can cause increased bearing friction, abnormal noise and overheating.

- Treatment: Regularly check lubrication condition, maintain proper amount of grease, and replace grease according to manufacturer’s recommended maintenance intervals.

Overheating:

- Diagnosis: Bearing overheating may be caused by excessive load, poor lubrication or bearing damage.

- Treatment: Check that the load is within the rated range, ensure proper lubrication, and repair or replace damaged bearings.

Vibration:

- Diagnosis: Bearing vibration can be caused by unbalanced loads, eccentricity or damaged bearings.

- Treatment: Balance the load, check for shaft eccentricity, and replace damaged bearings.

Abnormal Noise:

- Diagnosis: Abnormal noise may be caused by bearing damage, particles entering the bearing, or insufficient lubrication.

- Treatment: Check for bearing damage, clean the bearing area and ensure adequate lubrication.

Change In Axial Play:

- Diagnosis: Abnormal changes in axial play may be caused by improper installation, damage or deformation of the bearing housing.

- Treatment: Reinstall the bearing, repair the housing, and ensure that the axial play meets specifications.

Seal Failure:

- Diagnosis: Bearing seal failure may result in lubricant leakage and dust ingress, affecting bearing performance.

- Treatment: Replace damaged seals and ensure good seal performance.

Corrosion And Rust:

- Diagnosis: In wet or corrosive environments, bearings may be subject to corrosion and rust.

- Treatment: Select corrosion-resistant materials, regularly inspect and clean the bearings to ensure that the environmental conditions meet the requirements.

Bearing Deflection:

- Diagnosis: Bearing misalignment may be caused by improper shaft alignment, excessive loads or shock loads.

- Treatment: Re-align the bearings, ensure loads are within the rated range, and reduce shock loads.

In the mechanical system, pillow block bearings play an indispensable role, and their stabilizing support and guiding effects are directly related to the operating efficiency of the whole system. Through in-depth understanding of the pillow block bearing’s working principle, common faults and corresponding treatment methods, we can better maintain and manage this key component. Regular inspection, lubrication and proper mounting not only extends the life of the bearing, but also ensures the reliability and stability of the mechanical system, providing excellent performance and benefits to the industry.

References

- “Pillow block bearing” from Wikipedia;

More information about“Pillow block bearing“from The BIG Bearings store.