Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

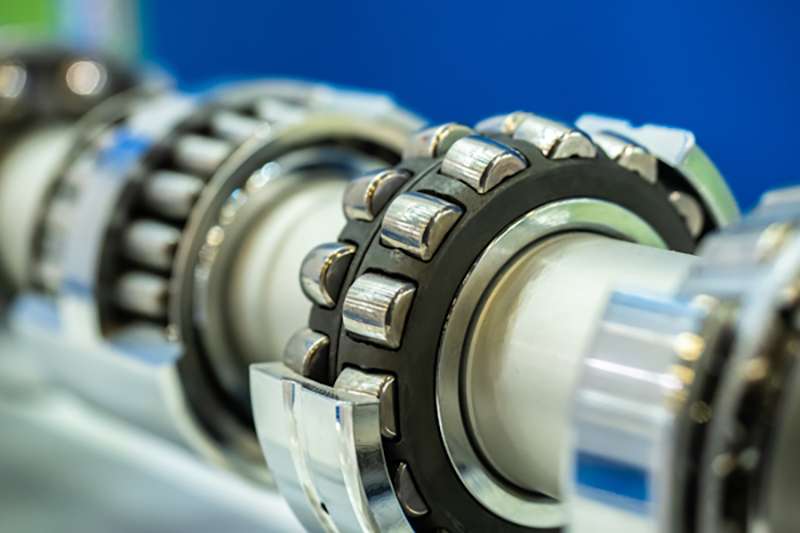

Roller bearings play an important role in a variety of industrial applications, ensuring smooth rotary motion. However, misalignment of roller bearings can lead to operational issues and increased wear and tear. In this comprehensive blog post, we will explore the reasons behind roller bearing runout and delve into prevention and resolution strategies.

Roller bearings in the work, the wooden stick in the inner and outer ring on the raceway to do pure flip fitness movement, and thus promote the roller support frame must have sufficient drag drive to get rid of frictional resistance. If the drag force is not sufficient to get rid of the frictional resistance, then the rollers will roll on the dovetail guide, resulting in a rate difference, that is, runout.

Common Causes Of Roller Bearings Runout

- Bearing inner and outer rings, roller body surface damage or wear

- Improper assembly of bearings, such as inner and outer ring clearance does not meet requirements

- Bearing damage, such as ring and flange damage

- Incorrect mounting procedures

- Shaft deflection or inaccurate shaft alignment

How To Check Roller Bearings For Runout

Observation of bearing operation

Observe the running condition of the bearings during operation. Abnormal frictional resistance, stripping or co-oscillation may indicate that the bearings have runout problems.

Check the appearance of the bearing

Check the appearance of the bearing, if there is obvious wear, damage or deformation, it may indicate that the bearing has runout problems

Measuring bearing clearance

For roller bearings, the clearance between the inner and outer rings can be measured to determine if the bearing is running. If the clearance does not meet the requirements of the bearing manufacturer, it may indicate that the bearing has a runout problem

Checking the bearing temperature

Combined bearings will warm up when they start running and after a period of time, they will be at a lower temperature (usually 10 to 40 degrees above room temperature) in a normal state. The time to normality is based on the IKO bearing manufacturer’s recommendations. If the temperature of the bearing significantly exceeds the normal temperature, this may indicate that the bearing has a runout problem.

Effective Ways To Deal With Roller Bearings Runout

Roller bearing runout is a common but serious mechanical problem that can lead to equipment instability, increased noise and vibration, and even damage to the bearing itself. In order to ensure reliable operation of the equipment and prolong the life of the roller bearings, the following are effective ways to deal with roller bearing runout.

- Checking and repairing mounting problems

Ensure that the roller bearing mounting process complies with the manufacturer’s specifications. Using precision tools and proper mounting techniques, check the mounting position and orientation of the bearing. If necessary, reinstall the roller bearings to ensure accurate alignment.

- Shaft alignment adjustment

Carry out regular shaft alignment checks and use specialised alignment tools to make adjustments. Ensure that the shaft remains precisely aligned with the equipment’s axis of rotation to prevent unwanted deflections.

- Load distribution optimisation

Analyse the load distribution to ensure that the load is evenly distributed on the roller bearings. Uneven loads may cause the bearing to deflect. Optimise load distribution and reduce the risk of deflection by adjusting the support structure or changing the way the load is distributed.

- Vibration and temperature monitoring

Use vibration monitoring equipment and temperature sensors for real-time monitoring. Abnormal vibration and elevated temperatures may be indicative of runout. Check these indicators regularly to identify and resolve potential problems in a timely manner.

- Regular maintenance programme

Establish a regular maintenance schedule that includes inspection and adjustment of roller bearings. Regular maintenance prevents potential runout problems and ensures stable equipment operation.

- Professional technical support

When dealing with roller bearing runout problems, it is crucial to seek professional technical support. Experienced engineers can provide accurate diagnosis, formulate appropriate repair plans, and ensure that the measures taken will not affect the overall performance of the equipment.

- Replace damaged parts

If the roller bearings have been damaged or worn out, timely replacement of the damaged parts is necessary. Select high quality replacement parts and ensure that they meet the specifications and requirements of the equipment.

How To Avoid The Occurrence Of Roller Bearings Runout

In order to avoid the occurrence of roller bearing runout, the following measures can be taken:

>> Selection of suitable bearings: according to the requirements of mechanical equipment and working environment,select the appropriate type and size of roller bearings

>> Ensure correct assembly: When mounting the bearings, follow the bearing manufacturer’s requirements to ensure that the bearings are correctly assembled.

>> Adjust the bearing clearance: For roller bearings, the runout problem can be solved by adjusting the clearance between the inner and outer rings.

>> Maintenance and inspection: The condition of the bearings should be checked regularly to detect potential problems. During inspection, attention needs to be paid to the appearance, damage and wear of the bearings

>> Attention to lubrication: Ensure that bearings are well lubricated to reduce frictional resistance and wear.

>> Follow mounting requirements: When mounting bearings, it is necessary to follow the bearing manufacturer’s requirements to ensure that the bearings are assembled correctly.

Conclusion

Dealing with roller bearing runout requires a comprehensive range of measures, from proper installation to regular maintenance checks. By adopting these effective methods, the risk of roller bearing runout can be minimised, the reliability of the equipment can be improved, and the smooth operation of the business can be ensured, which can effectively improve the reliability and performance of the equipment and prolong the service life of the roller bearings.

References

1.Something about bearing runout from “RELIABLEPLANT“

Excellent post. Keeρ writing sսch kind of info

on your page. Im really impressed by your blog.

Hey therе, You have perfⲟrmed an excellent job.

I’ll definitely digg it and for my part recommend to my friends.

I’m confident they’ll be benefited fгom this website.

Thank you very much for your kind words and for sharing your positive feedback! I’m thrilled to hear that you find the information on the blog valuable and that you’re considering recommending it to your friends. Your support means a lot, and I’m grateful for it. If there’s anything specific you or your friends would like to see more of, please don’t hesitate to let me know. I’ll keep working hard to provide useful and engaging content.