Categories

Revolutionize Your Machinery: Self-Lubricating Bearings 101

Table of Contents

Introduction

In the rapidly evolving landscape of machinery, a technological marvel stands poised to redefine the status quo: self-lubricating bearings. These cutting-edge components have the potential to fundamentally transform the way machinery operates, ushering in a new era of unparalleled efficiency and performance optimization.

Setting the Stage for Innovation in Machinery

The landscape of machinery is characterized by relentless innovation, with a constant quest to enhance performance and reliability. Amid this dynamic environment, self-lubricating bearings emerge as a groundbreaking solution, promising to address longstanding challenges and propel machinery into a future of smoother, more efficient operation.

The Role of Bearings in Machinery Performance

Before delving into the intricacies of self-lubricating bearings, it is essential to appreciate the pivotal role that traditional bearings play in the performance of machinery. These unassuming components bear the responsibility of reducing friction and supporting heavy loads, serving as indispensable elements in ensuring the seamless operation of diverse mechanical systems.

Understanding Traditional Bearings

Traditional bearings, while foundational to machinery, are not without their limitations. The reliance on external lubrication methods presents a set of challenges, including increased maintenance requirements, susceptibility to contamination, and variable performance under different operating conditions.

Challenges with Conventional Lubrication Methods

Limited Lifespan: Conventional lubricants, often mineral-based, can break down over time, requiring frequent replacements.

Temperature Sensitivity: They struggle to maintain effectiveness in extreme temperatures, leading to issues like evaporation in high heat or increased viscosity in cold conditions.

Contamination Risk: Conventional lubricants are prone to contamination by dust, dirt, and water, accelerating wear on machinery components.

Inefficient Distribution: Achieving uniform lubrication across moving parts can be challenging, with some areas receiving too much lubrication and others not enough, leading to uneven wear.

Addressing these challenges often involves exploring alternative lubrication technologies, such as synthetic lubricants, dry lubrication methods, or solid lubricants, which aim to overcome the limitations associated with conventional lubrication approaches.

The Impact of Friction on Machinery Efficiency

Friction has a significant impact on machinery efficiency and can result in various consequences that affect performance, energy consumption, and overall reliability. Here are key points outlining the impact of friction on machinery efficiency:

Energy Loss: Friction between moving parts transforms mechanical energy into heat, causing energy loss. This can decrease the overall efficiency of machinery as a significant portion of input energy is dissipated as heat rather than being utilized for useful work.

Increased Wear and Tear: Friction contributes to wear and tear on machine components. As surfaces rub against each other, material is gradually eroded, leading to the need for more frequent maintenance, repairs, and component replacement. This not only increases operational costs but also reduces the lifespan of the machinery.

Reduced Performance: Friction can hinder the smooth operation of machinery, leading to decreased performance. It may cause stiffness or resistance in moving parts, affecting the speed and accuracy of mechanical processes. This can be particularly detrimental in precision machinery and applications where consistency is crucial.

Heat Generation: The heat produced by friction can lead to elevated temperatures in machinery. Excessive heat can negatively impact lubricants, causing them to break down or evaporate more quickly, further increasing friction and wear. Overheating can also compromise the structural integrity of materials, leading to potential failures.

Addressing friction and its impact on machinery efficiency involves the use of lubricants, anti-friction coatings, precision engineering, and, in some cases, the adoption of innovative technologies designed to minimize frictional forces. Efforts to reduce friction contribute not only to improved efficiency but also to extended machinery lifespan and reduced environmental impact.

The Birth of Self-Lubricating Bearings

Origins and Evolution of Self-Lubricating Technology

Self-lubricating technology, a significant advancement in engineering, originated in response to the need for more efficient and low-maintenance machinery. The concept evolved as a solution to mitigate the challenges associated with conventional lubrication methods, such as limited lifespan and inefficient distribution. Early developments focused on incorporating solid lubricants, such as graphite or molybdenum disulfide, directly into materials or coatings, reducing friction between moving parts. Over time, the evolution of self-lubricating technology has embraced innovations like composite materials, polymers, and advanced coatings with inherent lubricating properties. This evolution has led to the creation of self-lubricating bearings, bushings, and other components that enhance machinery performance, reduce maintenance requirements, and extend operational lifespans in diverse industries.

Advantages of Self-lubricating Bearings over Traditional Bearings

Self-lubricating bearings have clear advantages over traditional counterparts. They eliminate or significantly reduce the need for external lubrication, leading to maintenance-free operation and extended lifespan. The embedded lubricating elements contribute to improved performance by minimizing friction and wear. These bearings are also more resistant to contamination, enhancing reliability. While they may have a higher upfront cost, self-lubricating bearings prove cost-effective over time due to reduced maintenance requirements. They are versatile, adaptable to various conditions, and align with environmental considerations by minimizing the use of traditional lubricants. Overall, self-lubricating technology offers a more efficient and sustainable solution for diverse industrial applications.

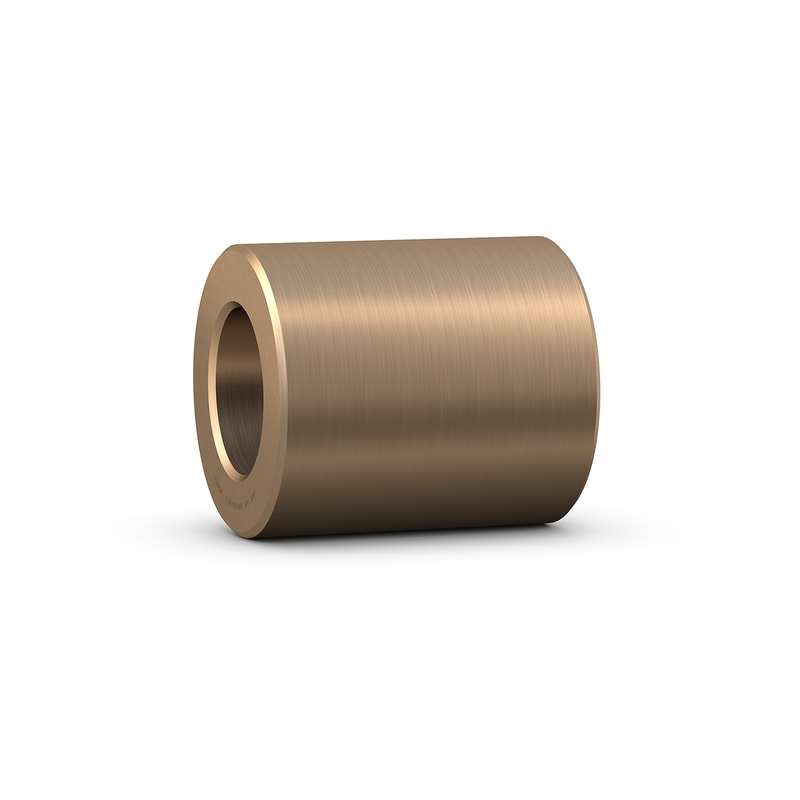

Key Components of Self-Lubricating Bearings

Self-lubricating bearings incorporate key components that enable them to operate without the need for external lubrication. The primary elements include:

Base Material: This is the main structural part, often made of metal or composite for strength.

Lubricating Elements: These are materials like graphite or PTFE embedded in the base to reduce friction between moving parts, eliminating the need for extra lubrication.

Binder or Matrix: This component holds the lubricating elements in place, ensuring even distribution for long-lasting effectiveness.

Fillers and Additives: Some bearings may include these to enhance specific properties like wear resistance or thermal stability.

Seals or Shields: Depending on the application, there might be protective features like seals to keep out contaminants, preserving the internal components and maintaining performance.

Understanding the interaction of these key components is essential in designing self-lubricating bearings tailored to specific operational requirements. The combination of a robust base material, effective lubricating elements, a reliable binder, and, if necessary, additional enhancements like seals or additives, collectively contributes to the overall efficiency and longevity of self-lubricating bearings in diverse industrial applications.

Applications Across Industries

Self-lubricating bearings find versatile applications across various industries due to their maintenance-free operation, reduced friction, and extended lifespan. Here are key sectors where these bearings are commonly utilized:

Automotive Industry: Self-lubricating bearings are employed in automotive applications such as chassis components, suspension systems, and steering systems. Their ability to withstand heavy loads and resist contamination makes them valuable in vehicles, enhancing durability and reducing maintenance requirements.

Aerospace and Aviation: In aircraft and aerospace applications, where reliability is critical, self-lubricating bearings are used in components like landing gear, control surfaces, and actuation systems. Their ability to operate in diverse environmental conditions without frequent maintenance makes them suitable for aviation applications.

Industrial Machinery: Self-lubricating bearings are widely used in industrial machinery, including conveyors, pumps, and manufacturing equipment. Their ability to handle high loads and operate in challenging environments improves the efficiency and reliability of various industrial processes.

Marine Applications: In marine environments, where bearings are exposed to moisture and corrosion, self-lubricating bearings are employed in components like ship propellers, winches, and steering systems. Their resistance to water and contaminants enhances reliability in maritime operations.

Medical Equipment: Self-lubricating bearings are used in medical devices and equipment, providing low-friction operation and reducing the need for frequent maintenance. They find applications in instruments, imaging devices, and various medical machinery.

The adaptability and performance advantages of self-lubricating bearings make them integral components in a wide range of industries, where they contribute to improved operational efficiency, reduced maintenance costs, and increased equipment reliability.

Conclusion

In conclusion, the emergence and evolution of self-lubricating bearings represent a transformative leap in the realm of machinery technology. These innovative components address the limitations of traditional bearings, offering maintenance-free operation, improved efficiency, and extended lifespan. By mitigating challenges associated with conventional lubrication methods, self-lubricating bearings have found applications across diverse industries, from automotive and aerospace to industrial machinery and medical equipment. Their ability to withstand heavy loads, resist contamination, and operate in various environmental conditions makes them indispensable in enhancing the performance and reliability of critical machinery components.