Exploring Solid Oil Bearings: Features, Advantages, and Applications

Introduction

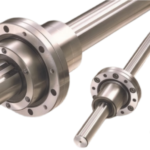

Solid oil bearings represent a remarkable innovation in the world of bearing technology, offering numerous advantages and applications across various industries. These bearings provide a sustainable, maintenance-free solution to traditional lubricated bearings, eliminating the need for continuous re-lubrication while maintaining excellent performance. In this article, we will delve into the features, advantages, and applications of solid oil bearings.

Features of Solid Oil Bearings

Solid oil bearings, also known as polymer or oil-impregnated bearings, are designed with unique features that set them apart from conventional lubricated bearings:

- Solid Lubricant: Solid oil bearings contain a specially formulated solid lubricant that is impregnated into the bearing material. This solid lubricant continuously releases onto the bearing surface during operation, ensuring consistent lubrication.

- Maintenance-Free: One of the most significant features of solid oil bearings is their maintenance-free nature. They eliminate the need for regular re-lubrication, reducing downtime and maintenance costs.

- High Load Capacity: Solid oil bearings have excellent load-carrying capabilities, making them suitable for heavy-duty applications.

- Environmental Resistance: They are highly resistant to environmental factors such as moisture, dust, and contaminants, making them ideal for challenging operating conditions.

Advantages of Solid Oil Bearings

Solid oil bearings offer several advantages that make them an attractive choice for various applications:

- Extended Service Life: The continuous release of lubricant ensures a longer service life for solid oil bearings compared to traditional bearings, reducing replacement frequency.

- Reduced Friction and Wear: Solid oil bearings provide low friction and minimal wear, leading to improved efficiency and reduced energy consumption.

- Quiet Operation: These bearings operate with minimal noise, making them suitable for applications where noise reduction is crucial.

- Corrosion Resistance: Solid oil bearings are highly resistant to corrosion, making them suitable for use in harsh environments.

- Cost Savings: The elimination of maintenance and lubrication requirements results in significant cost savings over time.

Applications of Solid Oil Bearings

Solid oil bearings find applications in a wide range of industries and settings:

- Industrial Machinery: They are commonly used in industrial machinery, such as conveyor systems, pumps, and fans, where continuous operation and minimal maintenance are essential.

- Agriculture: Solid oil bearings are ideal for agricultural equipment, including tractors, combines, and seeders, where they can withstand exposure to dust and moisture.

- Mining: In the mining industry, solid oil bearings are employed in heavy equipment like crushers, screens, and conveyor belts, where they endure demanding conditions.

- Food and Beverage: These bearings are well-suited for food and beverage processing equipment, as they eliminate the risk of contamination from lubricants.

- Renewable Energy: Solid oil bearings are increasingly used in wind turbines and solar tracking systems, where they reduce maintenance and enhance reliability.

Conclusion

Solid oil bearings represent a significant advancement in bearing technology, offering features like continuous lubrication, maintenance-free operation, and environmental resistance. Their advantages, including extended service life, reduced friction, and cost savings, make them a preferred choice across various industries. As industries continue to seek more efficient and sustainable solutions, solid oil bearings are poised to play a crucial role in meeting these demands.