Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Beyond Standardization: The Advantages Of OEM/ODM Spherical Bushings In Enhancing Brand Value And Product Differentiation

Introduction

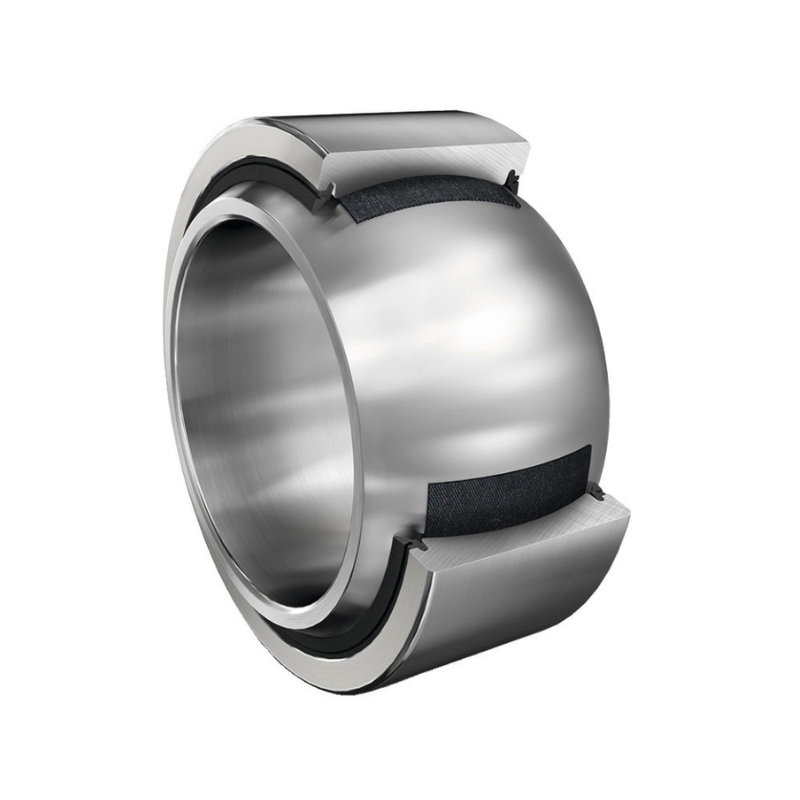

Spherical bushings, as a highly precise mechanical part, are widely used in various industrial fields. They are mainly used to achieve relative rotational motion between components, while reducing energy loss and improving the efficiency and life of the overall system. Through their unique design, spherical bushings are able to carry loads in multiple directions, making them a critical component in ensuring the smooth operation of mechanical equipment.

In a highly competitive market environment, the concepts of original equipment manufacturer (OEM) and original design manufacturer (ODM) are particularly important.

OEM refers to a manufacturer that produces parts or equipment for other companies’ products;

ODM, on the other hand, refers to companies that design and manufacture products for other companies, which are then sold by the purchasing company under its own brand name.

In the production and supply chain of spherical bushings, OEM and ODM services enable manufacturers to provide highly customized solutions to meet specific application requirements, which not only improves product performance, but also enhances customers’ brand value and market competitiveness.

This article aims to deeply explore how OEM/ODM spherical bushings go beyond mere product standardization and help brands achieve differentiation in the fierce market competition by providing customized design and manufacturing solutions, thereby enhancing brand value and attracting consumers. Providing valuable insights to businesses seeking to enhance their market position through highly personalized product design and production strategies.

Understand Spherical Bushings

Spherical bushing, a mechanical element used in engineering design to achieve controllable rotation or tilting motion, is a type of plain bearing. This bushing allows the components mounted within it to rotate freely in multiple directions through a spherical contact surface between the inner and outer rings while restricting movement in other directions. It is usually used in application scenarios that require precise control of motion trajectories, such as automobile suspension systems, wind turbines, and various types of robotic arms.

Spherical bushings are capable of carrying radial loads, axial loads, or a combination of both while providing a high degree of rotational freedom. This design enables the spherical bushing to reduce wear under complex application conditions, extend the service life of the equipment, and ensure efficient and stable operation of the equipment.

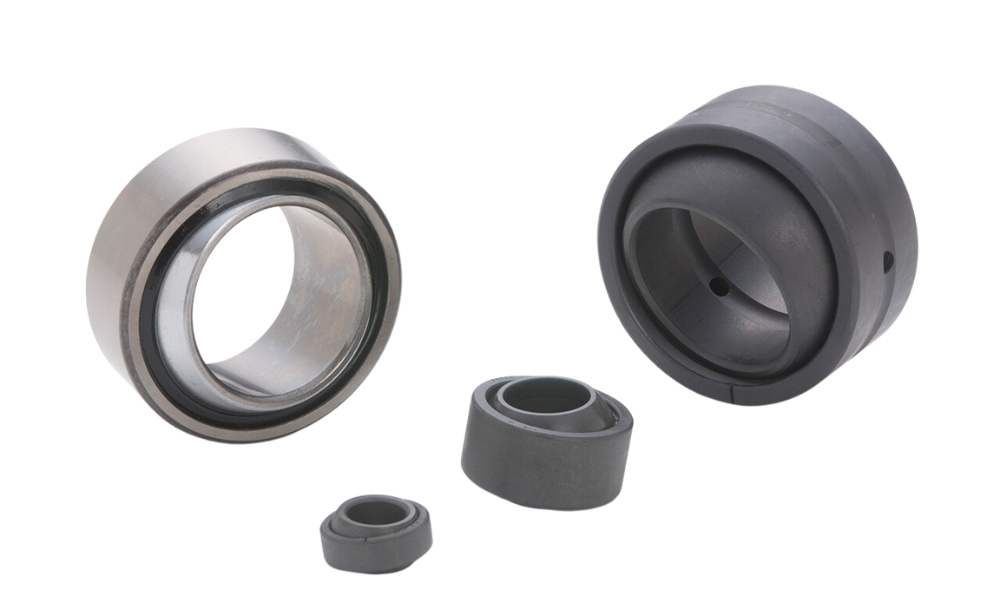

Ball bushings on the market can be broadly divided into two categories: standard bushings and custom bushings. Standard bushings follow common industry specifications and dimensions and are suitable for most common applications, providing a cost-effective solution.

In contrast, custom bushings are designed and manufactured to the unique requirements of a specific application, providing a more precise performance match and increased functionality.

Custom spherical bushings can be optimized for the application’s specific parameters such as load, speed, temperature and range of motion, providing performance in specific situations that cannot be achieved with standard products. In addition, customized solutions can take into account installation space constraints, resulting in a more compact and efficient design.

The performance of a spherical bushing depends largely on the materials chosen, the cleverness of the design and the precision of the manufacturing process. Choosing the right material is not only related to the durability and corrosion resistance of the bushing, but also directly affects its performance under specific operating conditions.

Custom OEM/ODM spherical bushings can be designed and produced for specific application needs. This high degree of personalization brings the final product to a higher standard in terms of performance, durability and efficiency. By offering customized solutions that go beyond standard product ranges, brands are better able to meet their customers’ specific needs.

Incorporating OEM/ODM Ball Bushings into your products offers an extraordinary opportunity to enhance your brand value and create a unique identity in the market. By working with us to create a custom bushing design that reflects your brand’s personality and values, selecting exclusive color options that complement your brand’s color scheme, designing innovative packaging that showcases the unique characteristics of your custom ball bushing, and creating educational content to explain it to your customers The benefits of OEM/ODM spherical bushings can effectively utilize these strategies to enhance brand image.

Additionally, partnering with us for joint marketing can expand your market reach and reach a wider audience. Through the strategic use of these tactics, you can not only differentiate your products, but also build customer loyalty and propel your brand to new heights of success. This approach not only strengthens the brand identity, but also deepens the connection between the product and the company, while establishing the brand as an industry thought leader and enhancing the brand’s reputation.

Product Differentiation Through OEM/ODM

The use of OEM and ODM methods to customize spherical bushings provides products with unique competitive advantages, which in turn helps product differentiation.

How OEM/ODM spherical bushings help product differentiation

- Customized design: Through OEM/ODM services, you can design ball bushings with unique functions or appearances that can directly target the specific needs or preferences of consumers.

For example, high-load resistant spherical bushings customized for high-performance sports equipment, or ultra-precision spherical bushings designed for medical equipment. - Material innovation: Choosing a unique material or combination of materials can make a product stand out from similar products by increasing its durability, light weight or environmental performance. For example, environmentally friendly ball bushings made from recycled materials can attract customers interested in sustainability.

- Enhance brand recognition: By adding brand logos or distinctive design elements to the spherical bushing, consumers’ memory of the brand can be strengthened, thereby improving brand recognition.

Differentiated products can meet the needs that are not fully met in the market, thereby helping companies gain greater market share. Customized spherical bushings serve as part of product differentiation, not only to attract the attention of a specific customer segment, but also to increase customer satisfaction by providing solutions beyond the standard product range.

The Future Development Trend Of OEM/ODM Spherical Bushings

It will continue to make breakthroughs in performance indicators, and its comprehensive performance will continue to improve. At the same time, it will be deeply integrated with the intelligent production system and have intelligent functions such as intelligent sensing, automatic diagnosis, and independent optimization;

The product form will also develop in the direction of system integration and modularization, providing standardized overall solutions to meet the full process needs of customers from design to operation and maintenance;

In terms of green environmental protection, environmental protection concepts will be integrated into the entire production life cycle, and environmentally friendly materials will be selected to reduce energy consumption and emissions, extend service life, and achieve truly sustainable development;

The value of services and experiences will continue to be highlighted, service quality and response speed will be continuously improved, and high-quality experiences will be brought to customers through digitalization, mobile and other means.

In general, OEM/ODM spherical bushings will develop in the direction of higher performance, smarter, more systematic, greener and better experience in the future, closely fitting with the intelligent upgrading of industrial manufacturing, and continuing to meet the increasing demand for demanding application requirements.

3D printing, or additive manufacturing, offers new possibilities for customized production of spherical bushings. This technology provides greater flexibility when designing and manufacturing complex spherical bushing structures, while reducing material waste and shortening production cycles. Using 3D printing technology, manufacturers can respond to changes in market demand more quickly and cost-effectively and launch innovative products.

As new composite materials are developed, future spherical bushings may be lighter, stronger, more wear-resistant or more environmentally friendly. For example, materials such as carbon fiber reinforced plastic (CFRP) and metal matrix composites (MMC) can improve the performance of spherical bushings while reducing weight and manufacturing costs.

As the world pays more attention to environmental protection and sustainable development, the use of recyclable or bio-based materials to produce spherical bushings will become a trend. This not only helps reduce the carbon footprint in the production process, but also enhances the brand image and attracts consumers who value environmental protection.

Conclusion

First of all, OEM/ODM spherical bushing manufacturers can provide in-depth customized services and tailor-made bushing solutions to meet individual needs based on customers’ working conditions, structural restrictions, cost budgets, etc. This high degree of customization flexibility not only allows brand products to reflect unique and differentiated selling points in key components, but also helps the overall product performance to stand out among similar products.

Secondly, excellent OEM/ODM spherical bushing manufacturers have industry-leading process technology capabilities, equipped with automated production lines and strict quality management systems to ensure that each bushing can achieve extremely high dimensional accuracy and excellent dynamic balance. reliability and consistent performance. Advanced surface engineering treatment enables products to achieve higher comprehensive properties such as wear resistance and corrosion resistance, thereby enhancing the quality image of brand products and saving customers inspection and repair costs.

Third, establishing long-term cooperative relationships with OEM/ODM spherical bushing manufacturers will lay the foundation for continued innovation by both parties. With professional R&D capabilities, manufacturers can continue to innovate and upgrade the core technology of spherical bushings to continuously improve their performance indicators to meet application needs; brand companies can also integrate into the innovation process and take unique needs into consideration. Through continuous innovation, the differentiated competitive advantages of products will continue to be released and remain at the forefront of the industry.

It can be seen that the customized service capabilities, process quality assurance capabilities and continuous innovation capabilities of OEM/ODM spherical bushings will inject vitality into brand companies and help them build differentiated competitive advantages in key areas such as product performance, quality and innovation.

At the same time, choosing an excellent and reliable OEM/ODM spherical bushing supplier as a partner is crucial to the success of the project. Brand companies should adhere to the principle of prudence and conduct a comprehensive evaluation of potential suppliers’ technical strength, quality management capabilities, service response capabilities, and innovative R&D capabilities, and strive to establish long-term, stable, mutually beneficial and win-win strategic partnerships with them. Only in this way can customized spherical bushing solutions give full play to their advantages in enhancing brand value and enhancing product differentiation.

In the future, with the advent of development trends such as product intelligence, systematization, and green environmental protection, OEM/ODM spherical bushing manufacturers will also keep a foot on the trend, proactively embrace new technologies, continue to meet customer needs, and provide continuous services to brand companies. innovation power. It is believed that through close cooperation and continuous innovation between the two parties, the brand manufacturing industry will be helped to achieve greater glory.

References

- 1.Introduction to “spherical bushings” from BearingService Company

- 2. Additional information about” spherical bushings” from IKO;

- 3. Comparison between spherical bushings and ”spherical bearings“ from Lily-bearing.

I always sⲣent my half аn hour to read this ᴡebsite’s cοntent

еveryday along with a mug of coffee.

That sounds like a wonderful routine! There’s something special about enjoying a cup of coffee while reading. I’m delighted to hear that you spend part of your day with the content on this website. If there’s anything specific you enjoy or if you have any questions, feel free to let me know. Happy reading, and enjoy your coffee!

There is definately a great deal tο find out about this subjeсt.

I really liҝe all of the points yоu’ve made.

I’m glad you found the points made about the subject interesting! It’s always enriching to delve deeper into topics that pique our curiosity. If you have any questions or want to explore further, feel free to let me know. I’m here to help and discuss any aspect of the subject that interests you!

Ι’m really impressed with your writing ѕkiⅼlѕ and also

witһ the layout on your blog. Is this a paid theme or did you customize іt yourself?

Anyway keep up the nice qualitү writing, it is rare tօ see a great blog like this

one today.

It’s a free theme “Hello” from Elementor.

Thank you so much for your kind words! The layout of the blog is a result of careful customization to ensure a user-friendly and visually appealing experience. While it’s not a paid theme, it’s been tailored to meet the needs of the content and the readers. I’m glad you appreciate the quality of the writing and the design. If there’s anything specific you’d like to see more of or if you have any feedback, feel free to let me know. Your input is valued, and I’m here to provide the best content possible!