Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Dynamic Load Analysis and Fatigue Testing of Spherical Plain Bearings

Introduction

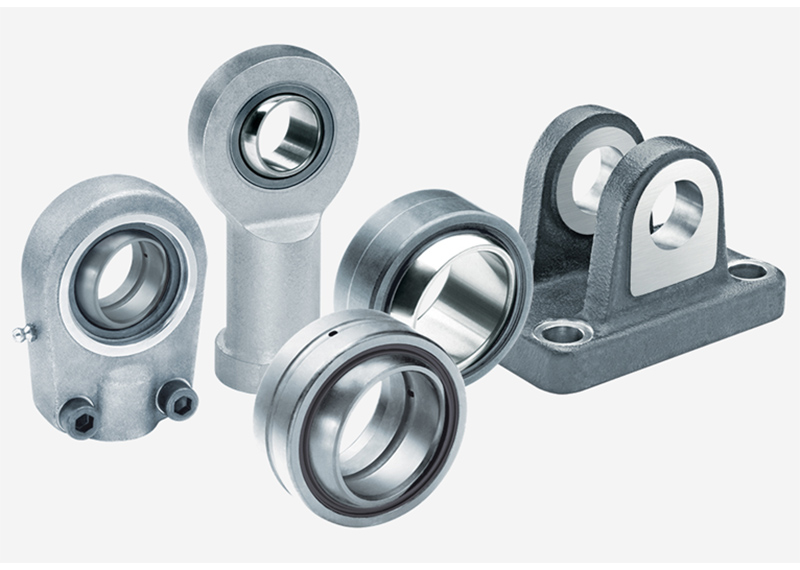

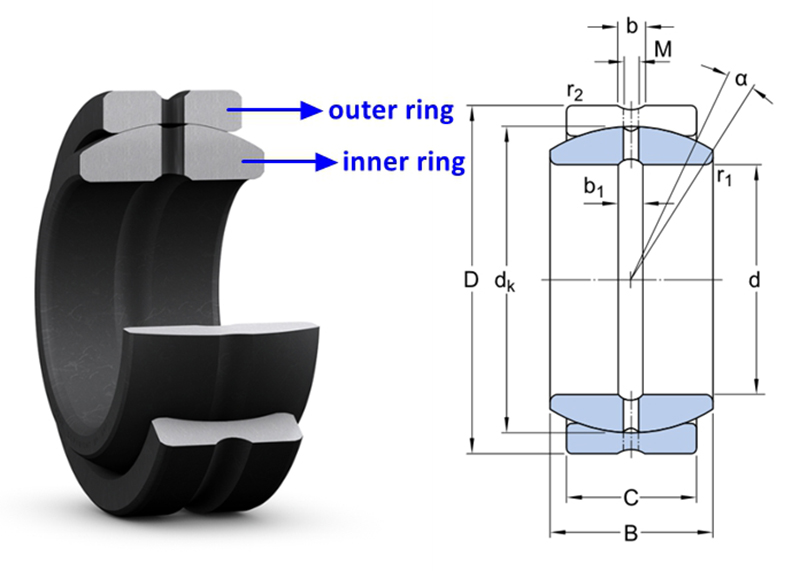

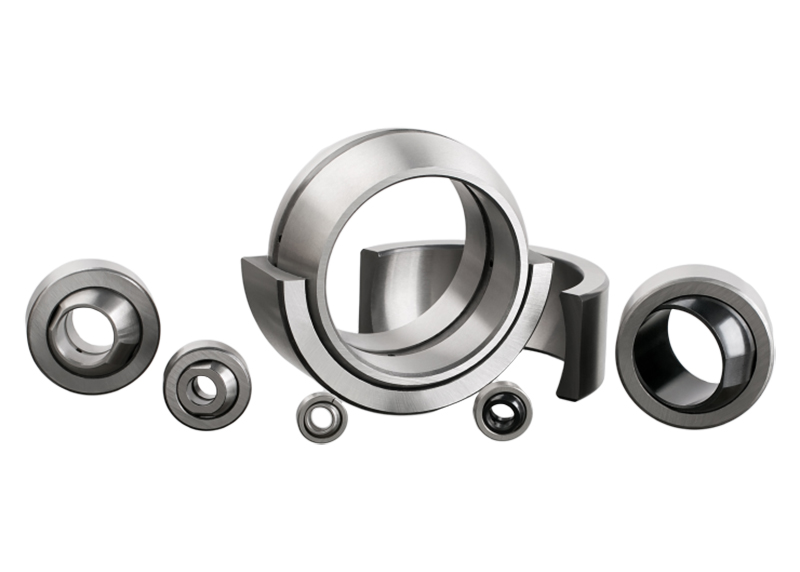

Spherical plain bearings, characterized by their spherical inner ring and a correspondingly spherical outer ring, are essential in mechanical systems requiring oscillating movements and load distribution. Common applications include automotive suspensions, aerospace linkages, and industrial machinery. Understanding dynamic load analysis and fatigue testing is crucial for these bearings, as it ensures their reliability and longevity under varying operational conditions. Dynamic load analysis helps in identifying load patterns and distribution, while fatigue testing assesses the bearing’s durability and resistance to failure over time. These procedures are vital in preventing unexpected breakdowns, enhancing performance, and guiding design improvements for better overall system reliability.

Dynamic Load Analysis

Fundamentals of Dynamic Load and Methods of Dynamic Load Analysis

Fundamentals of Dynamic Load

Dynamic load refers to the varying forces exerted on spherical plain bearings during operation, including fluctuating, impact, and oscillatory loads. These loads differ from static loads, which remain constant over time. Dynamic loads arise from the operational environment, such as speed variations, directional changes, and external forces. Understanding these loads is crucial because they significantly affect bearing performance and lifespan. Analyzing dynamic loads helps in predicting bearing behavior under real-world conditions, ensuring proper load distribution, and identifying potential stress points that could lead to premature failure, thus informing design and maintenance strategies for enhanced reliability.

Methods of Dynamic Load Analysis

Dynamic load analysis of spherical plain bearings employs various methods to assess load impacts accurately. Analytical methods involve mathematical models to predict load behaviors, while numerical simulations, like Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD), offer detailed insights into load distributions and interactions under different conditions. Experimental methods involve real-world testing using instruments such as load cells and strain gauges to measure actual loads on bearings. Each approach has its strengths, with analytical and numerical methods providing theoretical predictions and experimental methods validating these predictions. Combining these methods offers a comprehensive understanding of dynamic loads, guiding design improvements and maintenance practices to enhance bearing performance and reliability.

Dynamic Load Characteristics in Spherical Plain Bearings

Dynamic load characteristics in spherical plain bearings encompass load distribution, impact of misalignment, and frictional forces. Load distribution refers to how forces are spread across the bearing surfaces during operation, influencing wear patterns and stress concentrations. Misalignment impacts occur when the bearing’s inner and outer rings are not perfectly aligned, leading to uneven load distribution and increased stress on specific areas. Frictional forces, arising from the interaction between bearing surfaces, affect the bearing’s efficiency and heat generation. Understanding these characteristics is crucial for predicting bearing behavior under dynamic conditions, allowing for accurate assessments of performance and longevity. Addressing these factors helps in optimizing bearing design and maintenance practices, ensuring reliable operation in various applications.

Tools and Equipment for Dynamic Load Analysis

Tools and equipment for dynamic load analysis of spherical plain bearings are essential for accurately measuring and understanding load impacts. Key tools include load cells, which measure force and provide data on load magnitude and direction, and strain gauges, which detect deformation in the bearing material under stress. Data acquisition systems are used to collect and analyze the data from these instruments, enabling real-time monitoring and detailed analysis of load patterns. Additionally, advanced software for modeling and simulation, such as Finite Element Analysis (FEA), helps visualize and predict load behaviors. These tools collectively enable precise dynamic load assessments, guiding improvements in bearing design, enhancing performance, and ensuring reliability in various applications.

Fatigue Testing

Fatigue refers to the progressive and localized structural damage that occurs when a material is subjected to repeated loading and unloading. In bearings, fatigue failure typically manifests as cracks or fractures initiated at stress concentration points, leading to eventual component failure. This phenomenon is particularly significant in applications involving oscillating or rotating motions, where cyclic loading is prevalent. By comprehensively understanding fatigue mechanisms, engineers can develop effective fatigue testing methodologies to evaluate bearing performance and ensure durability in real-world operating conditions.

Fatigue Testing Procedures

These procedures involve subjecting test specimens to controlled cyclic loading, simulating the operational stresses experienced during their service life. Preparation of test specimens includes careful machining and surface finishing to ensure consistency and reproducibility. Load application methods, such as constant amplitude loading or variable amplitude loading, are employed to mimic real-world operating conditions accurately. Test environments play a critical role, with factors like temperature variations and lubrication conditions affecting fatigue behavior. Throughout the testing process, careful monitoring of fatigue-induced damage is essential, often utilizing non-destructive testing techniques and advanced instrumentation. By following rigorous fatigue testing procedures, engineers can assess the bearing’s resistance to fatigue failure and make informed decisions regarding design improvements and maintenance strategies for enhanced reliability.

Types of Fatigue Tests and Equipment for Fatigue Testing

Various types of fatigue tests are employed to evaluate the performance and durability of spherical plain bearings under different loading conditions. Rotating bending fatigue tests subject the bearing to cyclic bending stresses, simulating rotational motion commonly encountered in applications like automotive and aerospace systems. Axial fatigue tests apply cyclic axial loads to assess the bearing’s resistance to axial forces, prevalent in machinery and structural applications. Rolling contact fatigue tests involve applying cyclic radial loads to mimic the repetitive rolling motion experienced by bearings in various industrial equipment. Each type of fatigue test provides valuable insights into the bearing’s behavior under specific loading scenarios, guiding design improvements and maintenance strategies to enhance reliability and longevity in diverse operational environments.

Equipment for fatigue testing of spherical plain bearings plays a crucial role in assessing their durability and performance under cyclic loading conditions. Fatigue testing machines are specialized equipment capable of applying controlled cyclic loads to test specimens, simulating real-world operational stresses. These machines come in various configurations to accommodate different types of fatigue tests, such as rotating bending, axial, and rolling contact fatigue tests. Control and monitoring systems ensure precise control over the testing parameters and enable real-time monitoring of fatigue-induced damage. Additionally, data analysis tools are employed to analyze test results and derive valuable insights into the bearing’s fatigue behavior, guiding design enhancements and maintenance practices for improved reliability and longevity.

Analysis and Interpretation of Results

Data Collection and Processing

Data collection and processing are essential steps in the analysis and interpretation of fatigue testing results for spherical plain bearings. During testing, various parameters such as load magnitude, cycle count, and temperature are continuously monitored and recorded using advanced instrumentation. Signal processing techniques are then applied to the collected data to filter out noise and extract relevant information. Data filtering and noise reduction help enhance the accuracy of the results by eliminating unwanted artifacts and disturbances. Subsequently, statistical analysis techniques are employed to analyze the processed data, providing insights into the bearing’s fatigue behavior, including fatigue life, failure modes, and performance trends. By meticulously collecting and processing test data, engineers can make informed decisions regarding design optimizations and maintenance strategies to ensure the reliability and longevity of spherical plain bearings in diverse operating environments.

Failure Analysis

Failure analysis is a critical aspect of interpreting fatigue testing results for spherical plain bearings, aiming to identify the root causes of failure and prevent recurrence. This process involves a systematic examination of failed components to determine the mechanisms leading to their deterioration. Microscopic examination techniques, such as optical microscopy and scanning electron microscopy (SEM), allow engineers to inspect the fracture surfaces and identify characteristic features indicative of the failure mode, such as fatigue crack initiation and propagation. Additionally, advanced analytical tools, such as finite element analysis (FEA) and computational modeling, may be employed to simulate the stress distribution and predict failure modes under different loading conditions. By conducting comprehensive failure analysis, engineers gain valuable insights into the weaknesses of the bearing design or operating conditions, enabling them to implement targeted improvements and preventive measures to enhance reliability and durability in future applications.

Significance of Testing in Bearing Design

Improving Bearing Design

Improving bearing design through rigorous testing procedures is paramount for enhancing performance, reliability, and longevity in various applications. By subjecting spherical plain bearings to dynamic load analysis and fatigue testing, engineers can identify potential weaknesses and stress points within the design. Insights gained from testing inform iterative design improvements, such as optimizing material selection, refining geometrical configurations, and enhancing surface treatments to withstand dynamic operating conditions effectively. Additionally, testing facilitates the validation of theoretical models and simulation results, ensuring that the final design meets performance requirements and industry standards. Furthermore, continuous testing and refinement enable engineers to stay abreast of technological advancements and evolving application demands, leading to the development of more robust and efficient bearing solutions. Ultimately, the significance of testing in bearing design lies in its ability to drive innovation, mitigate risks, and deliver superior products that meet the evolving needs of industries worldwide.

Predictive Maintenance and Monitoring

Lessons Learned from Failures

Lessons learned from failures of spherical plain bearings offer invaluable insights into improving design, maintenance, and operational practices. By examining the root causes of failures, engineers can identify weaknesses in bearing design, material selection, or manufacturing processes. Common failure modes, such as fatigue cracks, wear patterns, or lubrication issues, provide essential clues to areas requiring attention. Moreover, failures often highlight shortcomings in maintenance practices or operating conditions, such as inadequate lubrication, overloading, or misalignment. Analyzing these failures enables engineers to implement preventive measures, such as improved maintenance schedules, enhanced training for personnel, or design modifications to address identified vulnerabilities. Additionally, failures serve as catalysts for innovation, driving the development of advanced materials, technologies, and predictive maintenance strategies to mitigate risks and improve reliability in future applications. By embracing the lessons learned from failures, engineers can continuously enhance bearing performance and ensure the longevity of critical machinery and equipment across various industries.

Conclusion

In conclusion, dynamic load analysis and fatigue testing are indispensable for ensuring the reliability and longevity of spherical plain bearings in diverse applications. By comprehensively understanding load characteristics and fatigue mechanisms, engineers can optimize bearing design, implement predictive maintenance strategies, and learn from past failures to drive continuous improvement. Through a combination of analytical, numerical, and experimental methods, coupled with advanced testing equipment and data analysis techniques, the industry can enhance bearing performance, mitigate risks, and meet evolving application demands. Embracing the lessons learned from failures enables the development of robust solutions that deliver superior reliability, efficiency, and cost-effectiveness, ultimately benefiting industries worldwide.

References

- 1.”Spherical bearing” from Wikipedia;

- 2. “Spherical Plain Bearings” from AST Bearings;

- 3. “Radial spherical plain bearings” from SKF Bearings.