Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

The Role Of Spherical Plain Bearings In Noise Control

Noise control has always been one of the key challenges in the industrial sector. As technology continues to evolve, spherical plain bearings are becoming a focal point in the field of noise control. This advanced bearing technology not only plays a key role in mechanical systems, but also has a significant impact on reducing noise levels.

Root Cause Of Noise

1. Friction

- Friction between mechanical parts is one of the major factors in noise generation.

- When mechanical parts move against each other, friction causes energy loss and vibration. The heat energy generated by this friction can be released in the form of acoustic energy, resulting in noise. The low-friction design of spherical plain bearings effectively reduces this noise generation by reducing friction.

2. Vibration

- Vibration in mechanical systems is another key factor in causing noise.

- Unstable mechanical movements and unbalanced loads cause vibrations that are transmitted through the structure to the surrounding environment, generating noise. The design of spherical plain bearings helps to control vibration and reduce its transmission, thereby reducing noise levels.

3. Improper lubrication

- Inadequate or improper lubrication can also lead to noise problems.

- Lubrication plays a key role in mechanical systems by helping to minimize friction and provide smooth motion. Lack of or improper lubrication can lead to increased friction, which can increase noise. Spherical plain bearings usually have an efficient lubrication system, which helps to maintain smooth operation of the system and reduce noise generation.

4. Unbalanced loads and design defects

- Unbalanced loads and design flaws in mechanical systems can cause vibration and noise.

- Incorrect mechanical design or unbalanced load distribution can lead to additional forces and vibration, and ultimately noise. Spherical plain bearings, through their design advantages, help to distribute loads smoothly and reduce unbalance in the system.

Spherical plain bearings reduce friction and noise

- Spherical design

Spherical plain bearings get their name from their spherical appearance. Their cylindrical shape allows the bearings to slide in many directions, not just in the direction of the center of the shaft. This spherical design provides a greater degree of freedom and enables the bearings to be adapted to complex motion requirements.

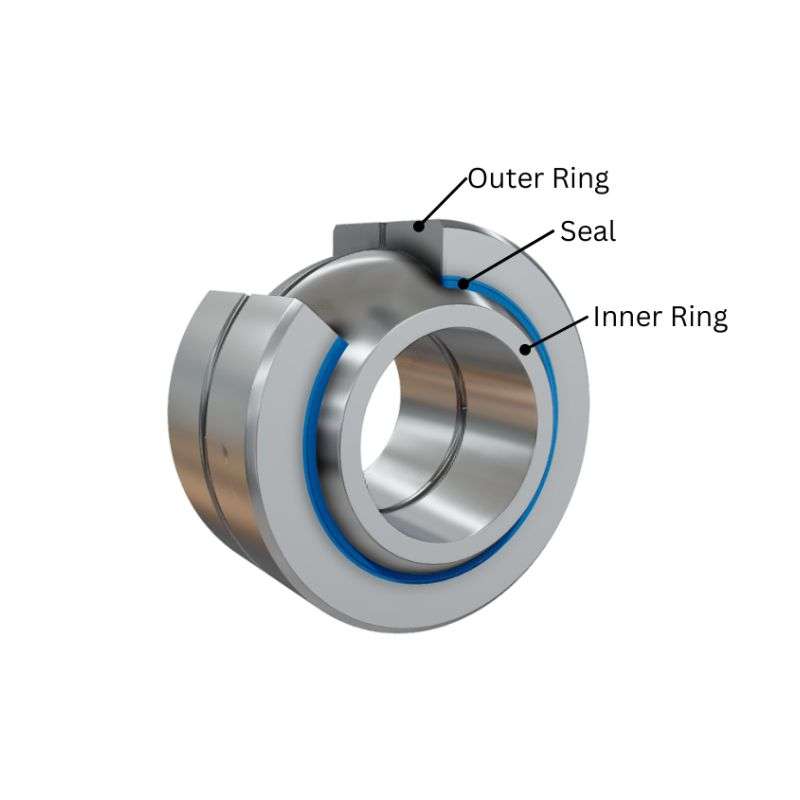

- Structure of inner ring and outer sphere

Spherical plain bearings consist of an inner ring and an outer sphere. The inner ring is attached to the shaft, while the outer spherical surface is attached to the housing or other components in the mechanical system. This construction enables the bearing to carry loads in radial and angular directions, providing more flexible motion support.

- Lubrication system

Spherical plain bearings are usually lubricated with a grease or oil lubrication system, which ensures that friction is reduced and the bearings are cooled effectively during movement. This helps to minimize energy loss and increase bearing life. A well-designed lubrication system also helps to reduce noise levels and provide smoother operation of mechanical systems.

- Self-carrying capacity

Spherical plain bearings have a high self-carrying capacity and can maintain stable operation even when there is no load or the load is not evenly distributed. This characteristic enables the bearings to adapt to complex working conditions and improves the reliability of the whole mechanical system.

- Corrosion and wear resistance characteristics

Spherical plain bearings usually use high-quality materials and surface treatment technology, so that they have excellent corrosion and wear resistance. This enables the bearings to operate stably in harsh environments and extends the service life of the system.

- Simplified mounting and maintenance

Spherical plain bearings are designed to simplify the mounting and maintenance process. Often, they can be designed so that they do not require regular lubrication or maintenance, which reduces the cost of use and improves the operability of the system.

Spherical plain bearings reduce friction and noise

- Optimized surface lubrication

Spherical plain bearings are often supplied with highly optimized surface lubrication systems, including the use of high-performance greases or oils. This helps to form a homogeneous, long-lasting lubricant film, which reduces friction and improves the sliding properties of the bearing. Optimized lubrication systems also help to cool the bearing and reduce energy losses during friction. - Selection of materials for friction coefficient reduction

The materials used in the manufacture of bearings have a direct influence on their friction characteristics. Spherical plain bearings are usually made of materials with low coefficients of friction, such as special alloys or coatings, to minimize friction losses. This choice of material helps to increase the efficiency of the bearing and to reduce the noise caused by friction during operation. - Optimization of geometric design

The geometric design of the bearing plays a key role in reducing friction and noise. The design of spherical plain bearings takes into account the optimization of geometry to minimize the number and extent of friction points. By reducing the surface contact area, the bearing is able to reduce friction and the resulting noise. - Precision manufacturing and fit

The manufacturing process for spherical plain bearings is often precision machined to ensure highly accurate dimensions and fits. This helps to minimize the clearance between bearing components, reducing friction and increasing the efficiency of the bearing’s motion. Precision manufacturing also helps to maintain bearing stability and reduce noise caused by irregular movements. - Vibration control technology

Vibration is one of the common sources of friction and noise. The design of spherical plain bearings effectively reduces the transmission of vibration through the use of vibration control techniques, such as vibration damping structures or materials. This helps to reduce noise levels, especially under high load or high speed operating conditions.

Key Player In Vibration Control

- Reducing Vibration Transmission:Vibration is transmitted through various parts of a mechanical system, causing noise and wear. The design of spherical plain bearings includes a vibration-damping structure and vibration-absorbing materials that effectively reduce the transmission of vibration. This helps maintain the stability of the entire system and alleviates vibration-related problems.

- Improve system stability:Uncontrolled vibration can lead to instability in mechanical systems, affecting their performance and life. Spherical plain bearings improve system stability through vibration control techniques, such as the use of elastomeric materials or vibration-damping structures. This is essential to ensure that the system remains reliable under all operating conditions.

- Reducing structural fatigue:Vibration causes fatigue in mechanical structures, which ultimately affects the life of the system. Spherical plain bearings help to reduce structural fatigue and extend the life of bearings and associated components through vibration control. This is particularly important under high load or high speed operating conditions.

- Improving Smoothness of Motion:Vibration can cause erratic motion in mechanical systems, affecting productivity and product quality. Spherical plain bearings help maintain smooth motion through vibration control, ensuring efficient operation of mechanical systems under different working conditions.

- Improving the working environment:Uncontrolled vibration generates noise and affects the quality of the working environment. Vibration control technology for spherical plain bearings helps to reduce noise levels, providing a quieter and more comfortable working environment for operators. This has a positive impact on productivity and employee satisfaction.

- Adaptation to complex working conditions:Mechanical systems may face different operating conditions and load variations during operation. The vibration control design of spherical plain bearings allows them to adapt to these variations, keeping vibration levels stable and ensuring reliable operation of the system under all conditions.

Case Studies

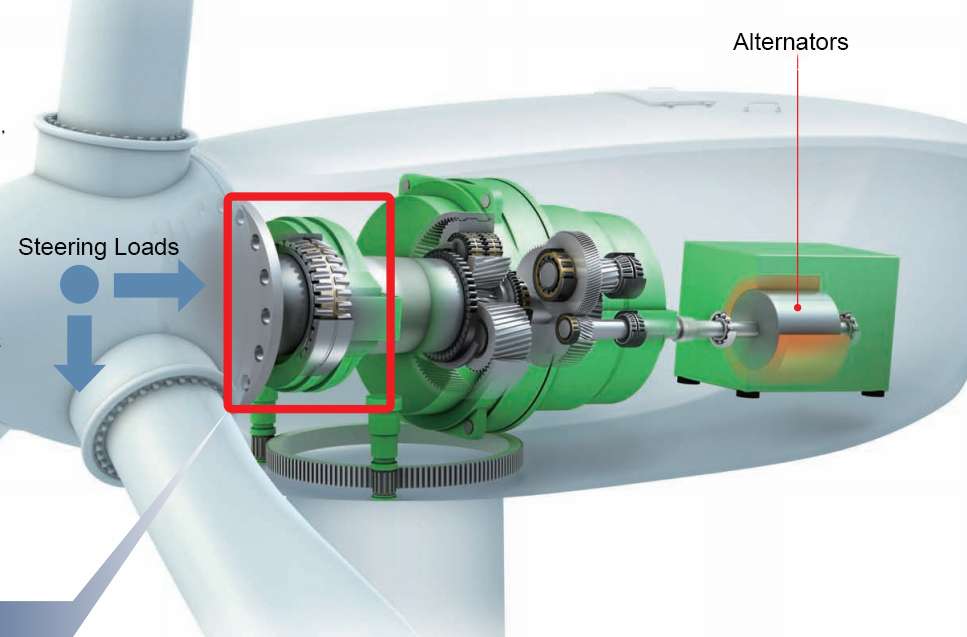

Wind turbine systems are an application scenario that demands high component performance and reliability. Spherical plain bearings play a key role in these systems, addressing challenges related to load carrying, friction and noise. Let’s dive into a case study that demonstrates the successful application of spherical plain bearings in wind turbine technology.

The Background

Wind turbine systems operate in harsh conditions and are subject to variable wind speeds and loads. These conditions require robust components that can withstand high stresses, reduce friction and maintain efficiency.

Case study details

Challenge: High loads and changing angles

Problem: Wind turbine blades experience dynamic and fluctuating loads as they capture wind energy. Conventional bearings often face difficulties in handling these varying loads and angles, leading to increased friction and wear.

Solution: Integration of spherical plain bearings

Implementation: Integration of spherical plain bearings into the regulation mechanism of the blades. Their unique design allows for multi-directional motion and high load capacity, enabling them to provide excellent performance under changing operating conditions.

This case study highlights the superior performance of spherical plain bearings when dealing with challenges in wind turbine systems. By integrating advanced bearing technology, the problems of high loads, changing angles, friction and noise were successfully addressed to provide stable, efficient and reliable operation of the wind turbine system. This also demonstrates the practical feasibility of utilizing innovative bearing designs in complex industrial applications.

Conclusion

In the quest for noise control, spherical plain bearings are showing their unique advantages. Their advanced design not only improves the efficiency of mechanical systems, but also effectively reduces noise levels. As an innovative technology in the industrial field, spherical plain bearings are making an important contribution to creating a quieter and more efficient working environment.

In future industrial applications, such advanced bearing technology will continue to drive the field forward, contributing to more sustainable and efficient industrial production.

References

- 1 “Plain bearing” from Wikipedia;

- 2 “Spherical plain bearings” from SKF Bearing designs and features