Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

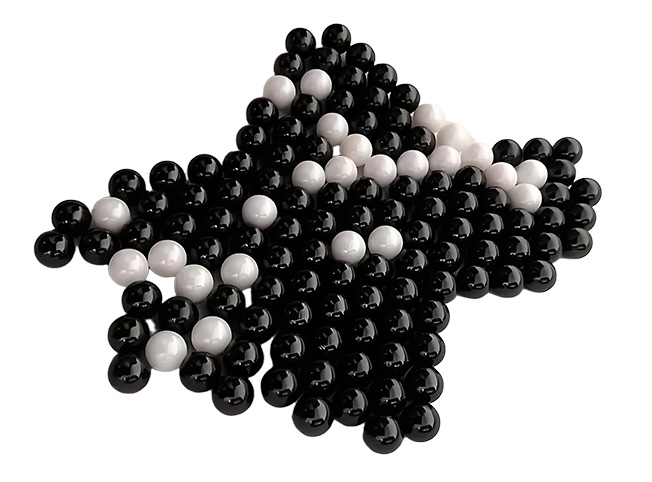

Steel Balls, Ceramic Balls, and Glass Balls in Bearing Applications

Bearings are crucial components in mechanical systems, reducing friction and supporting loads in rotating and linear motion. The type of ball material used in bearings significantly impacts their performance, durability, and suitability for different environments. Below is an overview of how steel, ceramic, and glass balls are used in bearing applications.

1. Steel Balls in Bearings

Steel balls are the most commonly used rolling elements in bearings due to their strength, durability, and cost-effectiveness.

Key Characteristics:

- High Load Capacity – Can withstand heavy radial and axial loads.

- Wear Resistance – Good resistance to wear under normal conditions.

- Magnetic Properties – Can be magnetized, making them unsuitable for some electronic applications.

- Moderate Corrosion Resistance – Stainless steel variants resist rust, but standard steel is prone to oxidation.

- High Density – Heavier than ceramic or glass, increasing centrifugal forces in high-speed applications.

Applications:

✔ Automotive Bearings – Used in wheel hubs, transmissions, and engines.

✔ Industrial Machinery – Found in conveyor systems, motors, and pumps.

✔ Aerospace Bearings – Used in landing gears and rotating components.

✔ Precision Bearings – Employed in watches, measuring instruments, and robotics.

Common Types Used in Bearings:

- Chrome Steel (AISI 52100) – High hardness, excellent wear resistance, widely used in high-load applications.

- Stainless Steel (440C, 304, 316) – Corrosion-resistant, used in food, medical, and marine applications.

2. Ceramic Balls in Bearings

Ceramic balls are often used in hybrid bearings (ceramic balls with steel races) or full-ceramic bearings (ceramic balls and ceramic races) for high-performance applications.

Key Characteristics:

- Lightweight – ~40% lighter than steel, reducing centrifugal forces and energy consumption.

- Higher Hardness – Reduces wear and increases bearing lifespan.

- Corrosion and Chemical Resistance – Ideal for extreme environments.

- Non-Magnetic & Non-Conductive – Suitable for electronic and medical applications.

- High Temperature Resistance – Performs well in extreme heat, making them ideal for aerospace and industrial applications.

Applications:

✔ High-Speed Bearings – Used in machine tools, turbines, and dental drills.

✔ Aerospace & Automotive Bearings – Found in turbochargers, jet engines, and electric motors.

✔ Chemical & Food Processing Bearings – Withstands corrosive chemicals and high-temperature sterilization.

✔ Medical Bearings – Used in MRI machines and surgical instruments due to non-magnetic properties.

Common Types Used in Bearings:

- Silicon Nitride (Si₃N₄) – High strength, wear resistance, and thermal stability.

- Zirconia (ZrO₂) – Tougher and more impact-resistant, used in applications requiring durability.

3. Glass Balls in Bearings

Glass balls are rarely used in high-load bearings but are valuable in specialized applications requiring chemical resistance, lightweight properties, and non-magnetic behavior.

Key Characteristics:

- Chemical and Corrosion Resistance – Does not react with most chemicals or oxidize.

- Non-Magnetic & Non-Conductive – Ideal for sensitive electronic applications.

- Lightweight – Reduces overall system weight.

- Low Load Capacity – Less durable than steel or ceramic, limiting its use in high-load applications.

Applications:

✔ Flow Meters & Chemical Bearings – Used in low-friction and chemically aggressive environments.

✔ Medical & Laboratory Equipment – Non-reactive properties make them ideal for medical applications.

✔ Optical and Scientific Instruments – Used in devices requiring high precision but minimal weight.

✔ Decorative Bearings – Found in furniture and specialty consumer products.

Common Types Used in Bearings:

- Borosilicate Glass – High thermal and chemical resistance.

- Fused Silica (Quartz) – Used in ultra-precise applications requiring high transparency and durability.

Comparison Table for Bearing Applications

| Property | Steel Balls | Ceramic Balls | Glass Balls |

|---|---|---|---|

| Load Capacity | High | Medium-High | Low |

| Wear Resistance | Good | Excellent | Poor |

| Corrosion Resistance | Moderate (stainless steel is better) | Excellent | Excellent |

| Weight | Heavy | Light (~40% less than steel) | Light |

| Magnetic Properties | Yes (except some stainless steel) | No | No |

| Electrical Conductivity | Yes | No | No |

| Temperature Resistance | High | Very High | Medium |

| Speed Performance | Good | Excellent (used in high-speed bearings) | Low |

| Cost | Low-Moderate | High | Low |

4.Pros of Steel Balls

High Strength and Durability

Steel balls are incredibly strong, capable of withstanding heavy radial and axial loads. Their high hardness makes them resistant to deformation, ensuring longevity in demanding applications.

Cost-Effectiveness for Bulk Production

Compared to ceramic and glass alternatives, steel balls are more affordable and readily available. This makes them the preferred choice for large-scale production where cost efficiency is paramount.

Wide Availability and Standardization

Steel balls are manufactured in a broad range of sizes, grades, and specifications, making them highly adaptable across industries. Their widespread use ensures easy sourcing and consistent quality from multiple suppliers.

5.Cons of Steel Balls

Susceptibility to Corrosion (Except Stainless Steel)

One major drawback of standard chrome steel balls is their tendency to rust when exposed to moisture and corrosive environments. Stainless steel varieties help mitigate this issue, but they come at a higher cost.

Heavier Weight Compared to Alternatives

Steel is significantly denser than ceramic or glass, which can limit its use in high-speed applications where reduced weight is beneficial. Increased weight also leads to higher energy consumption in dynamic systems.

Higher Friction in Certain Applications

Although steel balls are durable, they generate more friction than ceramic balls, which can lead to increased heat generation and energy loss in high-speed applications. Lubrication is often required to minimize wear.

6.Pros of Ceramic Balls

Lightweight for High-Speed Applications

Ceramic balls are 40% lighter than steel, reducing centrifugal forces in high-speed rotating systems. This makes them ideal for high-RPM bearings and aerospace applications.

Excellent Wear and Corrosion Resistance

Ceramic balls exhibit minimal wear over time, even under high-stress conditions. Their chemical inertness allows them to function in highly corrosive or lubricated environments without degradation.

High-Temperature Tolerance for Extreme Environments

Unlike steel, ceramic materials can withstand temperatures exceeding 1,000°C without losing structural integrity, making them perfect for turbines, furnaces, and high-heat applications.

7. Cons of Ceramic Balls

Higher Cost Compared to Steel Balls

Ceramic balls are significantly more expensive than steel due to their specialized production process and material costs. This can be a deterrent for budget-conscious buyers.

Brittle Nature Under Impact Stress

Despite their hardness, ceramic balls are more brittle than steel and can crack or fracture under heavy impact loads. This limits their use in shock-prone environments.

Limited Availability in Some Regions

Not all suppliers carry high-quality ceramic balls, which can lead to longer lead times and higher procurement costs.

8.Pros of Glass Balls

Chemically Inert and Highly Resistant to Corrosion

Glass balls do not react with acids, bases, or solvents, making them ideal for chemical processing applications.

Non-Magnetic and Electrically Insulating Properties

Glass balls are used in electrical insulation, electronic components, and MRI-compatible applications where non-magnetic materials are required.

Aesthetic Appeal for Decorative and Precision Applications

With their smooth, glossy appearance, glass balls are commonly used in luxury products, precision optics, and scientific instruments.

9.Cons of Glass Balls

Fragility and Low Impact Resistance

Unlike steel and ceramic, glass balls are highly brittle and can shatter on impact, limiting their industrial use.

Limited Load-Bearing Capacity

Glass balls lack the structural strength needed for heavy-duty applications, restricting their use to light-load environments.

Restricted Application in High-Wear Environments

Since glass wears down more quickly than metal or ceramic, it is not suitable for grinding media or high-friction bearings.

Conclusion:

Each type of ball—steel, ceramic, and glass—has distinct advantages that make it ideal for specific applications.

- Steel balls are strong, cost-effective, and widely used in bearings and industrial machinery.

- Ceramic balls offer superior hardness, wear resistance, and chemical stability, making them ideal for high-performance applications.

- Glass balls provide chemical resistance, non-magnetic properties, and aesthetic appeal, making them suitable for scientific and decorative purposes.

Choosing the right type depends on the specific application requirements, including load-bearing capacity, environmental conditions, and cost considerations.

Super-Duper website! I am loving it!! Will be back later to read some more. I am taking your feeds also.

Great write-up, I am regular visitor of one¦s site, maintain up the nice operate, and It’s going to be a regular visitor for a long time.

Great write-up, I’m regular visitor of one’s blog, maintain up the nice operate, and It is going to be a regular visitor for a long time.

This is the proper blog for anyone who needs to seek out out about this topic. You notice so much its nearly onerous to argue with you (not that I actually would need…HaHa). You definitely put a new spin on a topic thats been written about for years. Great stuff, simply nice!

Perfect piece of work you have done, this site is really cool with great information.

Wonderful work! This is the type of info that should be shared around the internet. Shame on the search engines for not positioning this post higher! Come on over and visit my website . Thanks =)

Wow! This could be one particular of the most useful blogs We have ever arrive across on this subject. Actually Magnificent. I am also an expert in this topic therefore I can understand your effort.

Thanks for sharing excellent informations. Your site is so cool. I am impressed by the details that you?¦ve on this website. It reveals how nicely you understand this subject. Bookmarked this website page, will come back for more articles. You, my friend, ROCK! I found simply the info I already searched all over the place and simply could not come across. What a perfect website.

I couldn’t resist commenting

Does your blog have a contact page? I’m having problems locating it but, I’d like to shoot you an email. I’ve got some suggestions for your blog you might be interested in hearing. Either way, great site and I look forward to seeing it improve over time.

I couldn’t resist commenting

Yay google is my queen helped me to find this great web site! .

I¦ve been exploring for a little bit for any high-quality articles or blog posts in this kind of space . Exploring in Yahoo I ultimately stumbled upon this website. Reading this info So i¦m glad to express that I’ve a very good uncanny feeling I came upon exactly what I needed. I so much no doubt will make certain to don¦t omit this site and provides it a glance on a continuing basis.

hey there and thank you in your information – I’ve definitely picked up anything new from proper here. I did alternatively expertise several technical points the usage of this site, since I skilled to reload the web site lots of instances previous to I may get it to load correctly. I have been brooding about in case your web hosting is OK? No longer that I am complaining, however sluggish loading cases occasions will often affect your placement in google and can injury your quality rating if ads and ***********|advertising|advertising|advertising and *********** with Adwords. Anyway I am adding this RSS to my e-mail and could glance out for much more of your respective exciting content. Make sure you update this again soon..

I am so happy to read this. This is the kind of manual that needs to be given and not the random misinformation that is at the other blogs. Appreciate your sharing this best doc.

Those are yours alright! . We at least need to get these people stealing images to start blogging! They probably just did a image search and grabbed them. They look good though!

Some really nice and utilitarian info on this web site, also I conceive the pattern has got fantastic features.

I have been reading out some of your posts and i can state pretty nice stuff. I will definitely bookmark your blog.

There are some interesting deadlines in this article however I don’t know if I see all of them center to heart. There is some validity but I will take maintain opinion until I look into it further. Good article , thanks and we wish extra! Added to FeedBurner as effectively

Hi, I think your site might be having browser compatibility issues. When I look at your website in Safari, it looks fine but when opening in Internet Explorer, it has some overlapping. I just wanted to give you a quick heads up! Other then that, fantastic blog!

You made some respectable points there. I looked on the web for the problem and located most people will associate with along with your website.

It’s hard to find knowledgeable people on this topic, but you sound like you know what you’re talking about! Thanks

I real glad to find this website on bing, just what I was looking for : D likewise saved to my bookmarks.

I have been browsing on-line greater than 3 hours lately, yet I never discovered any attention-grabbing article like yours. It’s lovely price enough for me. Personally, if all site owners and bloggers made excellent content material as you probably did, the web might be a lot more useful than ever before.

Regards for helping out, great information.

I have been examinating out some of your posts and i can claim pretty clever stuff. I will make sure to bookmark your site.

I wanted to thank you for this great read!! I definitely enjoying every little bit of it I have you bookmarked to check out new stuff you post…

Many thanks for the help in this question, now I will know.

I consider something truly special in this website.

great points altogether, you just gained a new reader. What may you recommend in regards to your publish that you simply made a few days ago? Any sure?

Write more, thats all I have to say. Literally, it seems as though you relied on the video to make your point. You clearly know what youre talking about, why throw away your intelligence on just posting videos to your blog when you could be giving us something enlightening to read?

I do consider all the ideas you’ve offered for your post. They are very convincing and will certainly work. Still, the posts are too short for novices. May you please lengthen them a bit from subsequent time? Thank you for the post.

Nice weblog here! Also your web site loads up fast! What web host are you the use of? Can I get your affiliate hyperlink in your host? I desire my website loaded up as fast as yours lol

You can definitely see your skills in the work you write. The world hopes for even more passionate writers like you who aren’t afraid to say how they believe. Always go after your heart.

That is really attention-grabbing, You are an overly professional blogger. I have joined your rss feed and stay up for in the hunt for more of your great post. Also, I’ve shared your website in my social networks!

I went over this web site and I think you have a lot of fantastic information, saved to fav (:.

Thanks for some other informative site. The place else may I get that type of information written in such a perfect approach? I’ve a challenge that I’m simply now running on, and I have been on the look out for such information.

Very interesting subject , appreciate it for putting up.

This actually answered my downside, thanks!

I’m curious to find out what blog platform you’re working with? I’m having some minor security issues with my latest blog and I would like to find something more secure. Do you have any suggestions?

Pretty element of content. I simply stumbled upon your site and in accession capital to assert that I get in fact enjoyed account your weblog posts. Anyway I will be subscribing to your augment and even I achievement you access consistently quickly.

I really like your writing style, excellent information, thankyou for posting : D.

An impressive share, I just given this onto a colleague who was doing a little analysis on this. And he in fact bought me breakfast because I found it for him.. smile. So let me reword that: Thnx for the treat! But yeah Thnkx for spending the time to discuss this, I feel strongly about it and love reading more on this topic. If possible, as you become expertise, would you mind updating your blog with more details? It is highly helpful for me. Big thumb up for this blog post!

You need to take part in a contest for one of the best blogs on the web. I will suggest this web site!

This really answered my problem, thank you!

Well I really liked studying it. This post procured by you is very effective for proper planning.

I like this site so much, saved to favorites.

I am really inspired along with your writing skills and also with the structure for your blog. Is this a paid subject matter or did you customize it your self? Either way keep up the nice quality writing, it’s rare to peer a great blog like this one these days..

I’ve read a few good stuff here. Certainly worth bookmarking for revisiting. I wonder how a lot attempt you place to make such a wonderful informative site.

Im not positive the place you are getting your info, but great topic. I needs to spend some time studying more or working out more. Thanks for magnificent information I was searching for this info for my mission.

This is the right blog for anyone who wants to find out about this topic. You realize so much its almost hard to argue with you (not that I actually would want…HaHa). You definitely put a new spin on a topic thats been written about for years. Great stuff, just great!

I’m still learning from you, but I’m improving myself. I certainly love reading all that is posted on your blog.Keep the posts coming. I liked it!

Thanks for helping out, excellent info .

Good V I should certainly pronounce, impressed with your website. I had no trouble navigating through all tabs as well as related info ended up being truly simple to do to access. I recently found what I hoped for before you know it at all. Reasonably unusual. Is likely to appreciate it for those who add forums or something, website theme . a tones way for your client to communicate. Excellent task..

I like this website its a master peace ! Glad I found this on google .

Heya i am for the primary time here. I came across this board and I find It truly useful & it helped me out much. I hope to give something back and aid others such as you aided me.

Thanks for some other excellent article. The place else may just anybody get that type of information in such an ideal means of writing? I’ve a presentation next week, and I am on the look for such information.

I love what you guys tend to be up too. This kind of clever work and exposure! Keep up the fantastic works guys I’ve added you guys to my personal blogroll.

I like what you guys are up also. Such intelligent work and reporting! Carry on the superb works guys I have incorporated you guys to my blogroll. I think it’ll improve the value of my web site 🙂

Lovely just what I was looking for.Thanks to the author for taking his time on this one.

I like this weblog very much so much fantastic info .

Hey there! I know this is somewhat off topic but I was wondering if you knew where I could locate a captcha plugin for my comment form? I’m using the same blog platform as yours and I’m having trouble finding one? Thanks a lot!

Nice post. I learn something more challenging on different blogs everyday. It will always be stimulating to read content from other writers and practice a little something from their store. I’d prefer to use some with the content on my blog whether you don’t mind. Natually I’ll give you a link on your web blog. Thanks for sharing.

I am forever thought about this, thankyou for posting.

Really Appreciate this blog post, how can I make is so that I receive an email every time you make a fresh article?

Yeah bookmaking this wasn’t a speculative decision great post! .

Hi there this is somewhat of off topic but I was wondering if blogs use WYSIWYG editors or if you have to manually code with HTML. I’m starting a blog soon but have no coding knowledge so I wanted to get guidance from someone with experience. Any help would be greatly appreciated!

I’ve been surfing online more than three hours today, yet I never found any interesting article like yours. It’s pretty worth enough for me. Personally, if all site owners and bloggers made good content as you did, the net will be a lot more useful than ever before.

Way cool, some valid points! I appreciate you making this article available, the rest of the site is also high quality. Have a fun.

Your place is valueble for me. Thanks!…

It’s hard to find knowledgeable people on this topic, but you sound like you know what you’re talking about! Thanks

Lovely just what I was searching for.Thanks to the author for taking his clock time on this one.

I¦ve recently started a web site, the information you offer on this web site has helped me tremendously. Thanks for all of your time & work.

Hi, i think that i saw you visited my blog thus i came to “return the favor”.I am trying to find things to improve my website!I suppose its ok to use a few of your ideas!!

You really make it seem so easy with your presentation but I find this topic to be really something which I think I would never understand. It seems too complicated and very broad for me. I’m looking forward for your next post, I will try to get the hang of it!

I really appreciate this post. I have been looking all over for this! Thank goodness I found it on Bing. You’ve made my day! Thx again!

Pretty! This was a really wonderful post. Thank you for your provided information.

Nice blog! Is your theme custom made or did you download it from somewhere? A design like yours with a few simple adjustements would really make my blog shine. Please let me know where you got your theme. Cheers

What i do not understood is actually how you’re not actually much more well-liked than you may be right now. You’re so intelligent. You realize therefore significantly relating to this subject, made me personally consider it from a lot of varied angles. Its like women and men aren’t fascinated unless it’s one thing to accomplish with Lady gaga! Your own stuffs excellent. Always maintain it up!

This is a very good tips especially to those new to blogosphere, brief and accurate information… Thanks for sharing this one. A must read article.

WONDERFUL Post.thanks for share..extra wait .. …

I’m not that much of a online reader to be honest but your sites really nice, keep it up! I’ll go ahead and bookmark your website to come back later. Many thanks

Hi there! I know this is kind of off topic but I was wondering if you knew where I could locate a captcha plugin for my comment form? I’m using the same blog platform as yours and I’m having trouble finding one? Thanks a lot!

Hello I am so glad I found your weblog, I really found you by accident, while I was researching on Digg for something else, Regardless I am here now and would just like to say thanks a lot for a tremendous post and a all round thrilling blog (I also love the theme/design), I don’t have time to read through it all at the minute but I have saved it and also added in your RSS feeds, so when I have time I will be back to read a lot more, Please do keep up the great job.

I would like to express thanks to the writer for bailing me out of this particular problem. Right after checking through the internet and seeing notions which are not beneficial, I figured my entire life was over. Living without the solutions to the problems you’ve resolved all through your entire website is a crucial case, as well as the kind that could have in a wrong way affected my career if I hadn’t discovered your web site. Your actual natural talent and kindness in playing with every aspect was tremendous. I don’t know what I would’ve done if I hadn’t come across such a thing like this. I’m able to at this point look forward to my future. Thanks a lot so much for your professional and sensible help. I will not hesitate to refer the sites to any person who needs to have care on this subject matter.

Very informative and fantastic bodily structure of content, now that’s user friendly (:.

I think you have remarked some very interesting points, regards for the post.

I absolutely love your blog and find almost all of your post’s to be exactly what I’m looking for. Does one offer guest writers to write content for yourself? I wouldn’t mind publishing a post or elaborating on a lot of the subjects you write in relation to here. Again, awesome web site!

Aw, this was a really nice post. In idea I wish to put in writing like this moreover – taking time and precise effort to make an excellent article… but what can I say… I procrastinate alot and certainly not seem to get one thing done.

I was very pleased to find this web-site.I wanted to thanks for your time for this wonderful read!! I definitely enjoying every little bit of it and I have you bookmarked to check out new stuff you blog post.

Great blog here! Additionally your website so much up very fast! What web host are you using? Can I am getting your affiliate link for your host? I desire my web site loaded up as fast as yours lol

Great ?V I should certainly pronounce, impressed with your website. I had no trouble navigating through all the tabs as well as related info ended up being truly easy to do to access. I recently found what I hoped for before you know it at all. Reasonably unusual. Is likely to appreciate it for those who add forums or anything, web site theme . a tones way for your customer to communicate. Excellent task..

I’m writing to make you know of the fine experience my girl gained checking the blog. She even learned a good number of issues, most notably what it is like to possess a marvelous coaching mindset to get most people clearly fully understand certain specialized topics. You really did more than people’s expected results. Thank you for showing the practical, trusted, revealing and cool tips on the topic to Julie.

You have noted very interesting details! ps nice site. “Sutton lost 13 games in a row without winning a ballgame.” by Ralph Kiner.

Hmm is anyone else encountering problems with the images on this blog loading? I’m trying to figure out if its a problem on my end or if it’s the blog. Any feed-back would be greatly appreciated.

Hi there, I discovered your website by means of Google whilst searching for a related subject, your site got here up, it appears to be like good. I have bookmarked it in my google bookmarks.

I don’t ordinarily comment but I gotta state thanks for the post on this great one : D.

certainly like your website but you need to take a look at the spelling on several of your posts. Many of them are rife with spelling problems and I to find it very bothersome to tell the reality nevertheless I will certainly come again again.

Helpful info. Lucky me I discovered your site accidentally, and I am stunned why this accident did not happened earlier! I bookmarked it.

Very interesting topic, thanks for posting.

I have not checked in here for some time as I thought it was getting boring, but the last several posts are great quality so I guess I will add you back to my everyday bloglist. You deserve it my friend 🙂

Some genuinely nice stuff on this web site, I enjoy it.

I like this blog its a master peace ! Glad I detected this on google .

Magnificent beat ! I wish to apprentice at the same time as you amend your web site, how can i subscribe for a blog web site? The account aided me a appropriate deal. I have been tiny bit acquainted of this your broadcast provided shiny transparent idea

After I originally commented I clicked the -Notify me when new feedback are added- checkbox and now every time a comment is added I get four emails with the identical comment. Is there any way you may take away me from that service? Thanks!

Thanks for the sensible critique. Me & my neighbor were just preparing to do some research on this. We got a grab a book from our area library but I think I learned more from this post. I am very glad to see such wonderful information being shared freely out there.

Excellent read, I just passed this onto a colleague who was doing some research on that. And he actually bought me lunch since I found it for him smile Thus let me rephrase that: Thanks for lunch! “Bill Dickey is learning me his experience.” by Lawrence Peter Berra.

My brother suggested I might like this website. He was once entirely right. This publish truly made my day. You can not believe just how much time I had spent for this info! Thanks!

Excellent site you have here but I was wondering if you knew of any message boards that cover the same topics talked about in this article? I’d really like to be a part of online community where I can get feedback from other experienced people that share the same interest. If you have any suggestions, please let me know. Thanks a lot!

I couldn’t resist commenting

Woah! I’m really digging the template/theme of this blog. It’s simple, yet effective. A lot of times it’s challenging to get that “perfect balance” between usability and appearance. I must say you’ve done a great job with this. In addition, the blog loads very quick for me on Opera. Superb Blog!

I was examining some of your posts on this site and I believe this site is really instructive! Keep putting up.

Some really excellent information, Glad I noticed this. “Ready tears are a sign of treachery, not of grief.” by Publilius Syrus.

As I website owner I believe the subject material here is rattling excellent, regards for your efforts.

Hello! I could have sworn I’ve been to this blog before but after browsing through some of the post I realized it’s new to me. Anyways, I’m definitely happy I found it and I’ll be book-marking and checking back frequently!

Hello very cool web site!! Guy .. Excellent .. Wonderful .. I’ll bookmark your site and take the feeds also?KI am glad to find numerous useful information here within the submit, we want develop extra strategies in this regard, thanks for sharing. . . . . .

At this time it appears like Movable Type is the preferred blogging platform out there right now. (from what I’ve read) Is that what you’re using on your blog?

I think other web-site proprietors should take this website as an model, very clean and wonderful user genial style and design, let alone the content. You’re an expert in this topic!

I just like the valuable information you supply for your articles. I’ll bookmark your blog and test again right here frequently. I’m relatively certain I’ll be told a lot of new stuff proper right here! Good luck for the following!

Wohh exactly what I was searching for, thankyou for putting up.

We’re so glad you found exactly what you were looking for! Thank you for your kind words. If you need anything else or have more questions, don’t hesitate to reach out. We’re happy to help!

Magnificent site. Lots of helpful info here. I?¦m sending it to some buddies ans additionally sharing in delicious. And naturally, thank you to your sweat!

Thank you so much for the kind words and for sharing our site with your friends! We’re thrilled to hear that you found the information helpful. If you or your buddies have any questions or need more details, feel free to reach out. We’re always happy to help!

I got what you intend,bookmarked, very nice site.

Thank you for bookmarking our site! We’re glad you found it useful. If you ever need more information or have any questions, feel free to reach out!

This web site is really a walk-through for all of the info you wanted about this and didn’t know who to ask. Glimpse here, and you’ll definitely discover it.

Thank you for the great feedback! We’re glad you found the site helpful and informative. If you ever have more questions or need further details, don’t hesitate to reach out. We’re here to help!

This blog is definitely rather handy since I’m at the moment creating an internet floral website – although I am only starting out therefore it’s really fairly small, nothing like this site. Can link to a few of the posts here as they are quite. Thanks much. Zoey Olsen

Appreciate it for helping out, good information. “Riches cover a multitude of woes.” by Menander.

This site is my intake, very excellent style and perfect content material.

Thank you so much for your kind words! We’re glad you’re enjoying both the style and content of the site. If you ever have any suggestions or need further information, feel free to reach out—we’re here to help!

I truly appreciate this post. I?¦ve been looking everywhere for this! Thank goodness I found it on Bing. You have made my day! Thx again

We’re so glad you found us through Bing! 😊 Thank you for your kind words—we’re thrilled to have made your day. If you need any more information or have questions in the future, feel free to reach out. We’re here to help!

There is apparently a bundle to know about this. I assume you made some nice points in features also.

Thank you for your comment! We’re glad you found the points helpful. If you’d like more details or have any questions about the bundle or features, feel free to ask—we’re happy to provide further information!

I carry on listening to the news update speak about receiving boundless online grant applications so I have been looking around for the most excellent site to get one. Could you advise me please, where could i find some?

Thank you for reaching out! While our focus is on providing industry insights, we recommend checking official government websites, grant directories, or industry-specific funding sources for reliable grant opportunities. If you have a specific area in mind, we’d be happy to point you in the right direction. Let us know how we can assist

Yay google is my queen aided me to find this outstanding website ! .

We’re glad Google led you to us! 😄 Thanks for your kind words—we’re happy you found our website helpful. If there’s anything specific you’re looking for, feel free to ask. We’re always here to help!

What’s Happening i’m new to this, I stumbled upon this I’ve found It positively helpful and it has helped me out loads. I’m hoping to give a contribution & aid different users like its aided me. Great job.

Welcome! We’re so glad you found our content helpful. It’s always great to hear that our insights are making a difference. We appreciate your willingness to contribute and support others—knowledge sharing benefits everyone! If you ever have questions or insights to share, we’d love to hear from you. Thanks for your kind words!

Absolutely composed written content, thanks for information .

Thank you for your kind words! We’re glad you found the content valuable. If there’s anything else you’d like to learn more about, feel free to let us know—we’re always happy to share insights!

Nice read, I just passed this onto a colleague who was doing a little research on that. And he actually bought me lunch as I found it for him smile Thus let me rephrase that: Thanks for lunch!

We’re glad you found the article helpful—and even happier to hear it earned you a lunch! 😄 Thanks for sharing it with your colleague. If you ever need more insights or have any questions, we’re always here to help. Enjoy your next meal on us (well, at least in spirit)!

Thank you, I’ve just been searching for information approximately this subject for a while and yours is the best I’ve discovered till now. But, what in regards to the conclusion? Are you positive concerning the source?

Thank you for your kind words! We’re glad you found our information helpful. Regarding the conclusion, we strive to provide well-researched and accurate insights based on industry expertise and reliable sources. If you have any specific concerns or need further clarification, we’d be happy to discuss them. Let us know how we can assist you further!

I was just looking for this information for some time. After six hours of continuous Googleing, finally I got it in your site. I wonder what’s the lack of Google strategy that don’t rank this type of informative web sites in top of the list. Normally the top websites are full of garbage.

We’re so glad you found the information you were looking for! It means a lot to us that our content was helpful after your extensive search. We always strive to provide valuable, in-depth insights, and we truly appreciate your support. Hopefully, search engines will catch up! 😄 In the meantime, feel free to bookmark our site for future reference. Let us know if there’s anything else we can cover for you!

Wonderful post however I was wanting to know if you could write a litte more on this subject? I’d be very thankful if you could elaborate a little bit more. Thank you!

Thank you for your kind words and interest in the topic! We’re always looking to provide deeper insights, and we’d love to elaborate further. If there’s a specific aspect you’d like us to expand on, feel free to let us know—we’re happy to dive deeper! Stay tuned for more in-depth content, and we appreciate your support! 🚀

Good info. Lucky me I reach on your website by accident, I bookmarked it.

We’re glad you found us—what a great accident! 😊 Thank you for bookmarking our site! We’re always sharing valuable insights on OEM/ODM manufacturing, so stay tuned for more. If there’s anything specific you’d like to learn about, feel free to let us know. Looking forward to having you back! 🚀

This is the right blog for anyone who wants to find out about this topic. You realize so much its almost hard to argue with you (not that I actually would want…HaHa). You definitely put a new spin on a topic thats been written about for years. Great stuff, just great!

Thank you for your thoughtful comment! We’re glad you found our blog insightful and engaging. We strive to bring fresh perspectives and valuable information to the conversation, especially in the ever-evolving world of OEM/ODM manufacturing. Your support means a lot, and we’d love to hear if there are any specific topics you’d like us to explore. Stay tuned for more great content—hope to see you back soon! 🚀

Thanks for sharing superb informations. Your web site is so cool. I am impressed by the details that you¦ve on this website. It reveals how nicely you perceive this subject. Bookmarked this website page, will come back for extra articles. You, my friend, ROCK! I found simply the info I already searched all over the place and just could not come across. What a great site.

Thank you for your kind words! We’re thrilled to hear that you found our website informative and valuable. It’s our goal to provide insightful content that helps professionals like you navigate the world of OEM/ODM manufacturing with confidence. We truly appreciate your support and your bookmark—stay tuned for more articles coming soon! If there’s a specific topic you’d like us to cover, feel free to let us know. Looking forward to seeing you back here! 🚀

Sweet blog! I found it while browsing on Yahoo News. Do you have any tips on how to get listed in Yahoo News? I’ve been trying for a while but I never seem to get there! Thank you

Hi there,

Thanks so much for the compliment! We’re glad you stumbled upon our blog. As for getting listed on Yahoo News, it can be a bit tricky, but here are a few tips that might help:

1.Quality Content – Consistently creating high-quality, original content that resonates with your target audience is key.

2.Engage with Media Outlets – Build relationships with journalists or media outlets that are featured on Yahoo News. You can do this by pitching relevant stories or press releases.

3.SEO Optimization – Ensure your website and articles are optimized for search engines to increase visibility, as Yahoo News often pulls from top-ranking articles.

4.Social Media Sharing – Promoting your content across platforms can help generate traffic and increase your chances of getting noticed by media outlets.

Hope this helps! Best of luck, and feel free to reach out if you have more questions.

Hello There. I found your weblog using msn. That is an extremely well written article. I’ll be sure to bookmark it and return to read extra of your useful information. Thanks for the post. I’ll certainly return.

Hi there,

Thank you so much for your kind words! We’re thrilled to hear that you found the article useful. We’ll be sure to keep sharing valuable insights, and we look forward to having you return to read more. Don’t hesitate to reach out if you have any questions or need further information.

Excellent items from you, man. I’ve be aware your stuff prior to and you’re simply too fantastic. I actually like what you have got right here, certainly like what you’re saying and the way in which through which you say it. You make it entertaining and you still care for to keep it wise. I can not wait to read much more from you. That is really a wonderful website.

Wow, thank you so much for the kind words! We’re thrilled that you enjoy the content and find it both entertaining and insightful. Your feedback truly means a lot to us, and we can’t wait to share more with you in the future. Stay tuned for more great posts—and feel free to reach out anytime if you have thoughts or questions!

Thanks for the sensible critique. Me & my neighbor were just preparing to do some research about this. We got a grab a book from our local library but I think I learned more clear from this post. I’m very glad to see such great information being shared freely out there.

There are actually loads of details like that to take into consideration. That could be a nice point to carry up. I provide the ideas above as common inspiration but clearly there are questions like the one you deliver up the place the most important thing might be working in honest good faith. I don?t know if finest practices have emerged round things like that, but I am positive that your job is clearly recognized as a good game. Each boys and girls really feel the impact of just a second’s pleasure, for the rest of their lives.

I have been checking out some of your stories and i can claim clever stuff. I will surely bookmark your website.

I am glad to be one of several visitors on this great internet site (:, thankyou for putting up.

Way cool, some valid points! I appreciate you making this article available, the rest of the site is also high quality. Have a fun.

Thank you so much for your kind words! We’re glad you found the article helpful and appreciate you checking out the rest of the site. We’ll keep working hard to maintain that quality. Have a great day, and don’t hesitate to reach out if you need anything else!

Some times its a pain in the ass to read what blog owners wrote but this website is very user genial! .

Thanks for the feedback! We’re thrilled to hear you find our site user-friendly. We strive to make content as clear and engaging as possible, so it’s great to know it’s working for you. Feel free to reach out if there’s anything else you’d like to see!