Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Customized Bearings: The Bespoke Choice To Enhance Industrial Operations

Introduction

Modern industry’s demands on machinery continue to increase, and in the pursuit of innovation and efficiency, off-the-shelf bearings may not always meet the unique needs of each application. At this time, the customized solution for customized bearings becomes particularly important. By customizing bearings to specific requirements, machinery can be unleashed to perform efficiently, thereby driving increased productivity. This article takes a deep dive into the world of custom bearings and explores their unique advantages.

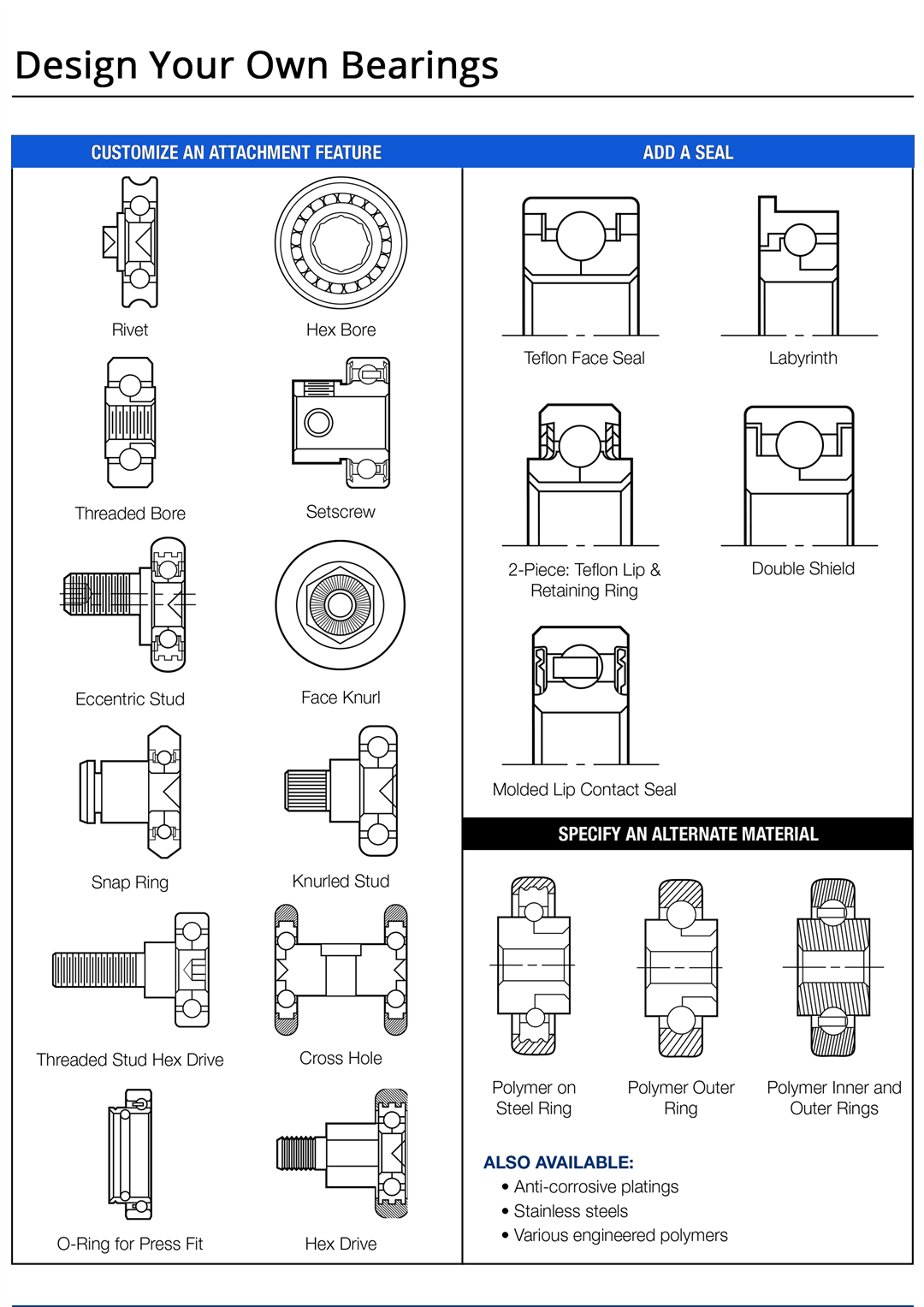

Customized Bearings Design And Manufacturing

Customized Bearings Design:

The design of customized bearings requires consideration of the following factors:

- Application requirements: Load, speed, operating conditions, etc. that the bearing needs to withstand.

- Material Selection: Selection of the appropriate bearing material according to the application requirements, e.g. bearing steel, stainless steel, ceramic, etc.

- Size and shape: Design the bearing according to the specific size and shape of the equipment.

- Precision requirements: The precision level of the bearing needs to meet the precision requirements of the equipment.

- Sealing and lubrication: Select the appropriate sealing and lubrication method according to the working conditions.

Customized bearings are designed by professional engineers, and designed and calculated according to the specific needs of customers to ensure that the bearings can meet the application requirements.

Customized Bearings Manufacturing:

The manufacture of customized bearings requires professional equipment and process, using high-precision processing equipment to process various parts of the bearings, heat treating the bearings by adopting quenching, tempering, etc., and chromium-plating or spraying the surface of the bearings, etc., in order to improve the hardness, abrasion, and corrosion resistance of the bearings; and strict quality control is required to ultimately ensure the quality and performance of the bearings.

Materials For Customized Bearings

When selecting materials for custom bearings, several factors need to be considered, including the environment in which they will be used, loads, speeds, temperatures, and desired characteristics. The following is a general analysis of bearing rings, cages, coatings and lubrication materials:

Bearing Ring Materials

Bearing Steel:

- 52100 Bearing Steel: High hardness, high wear resistance, and good fatigue resistance, suitable for high-performance bearings.

- 440C Bearing Steel: High hardness, high corrosion resistance, suitable for high-temperature and high-corrosion environments.

- GCr15 Bearing Steel: Low cost, suitable for general applications.

Stainless Steel:

- 304 Stainless Steel: Good corrosion resistance, suitable for food processing, chemical industry, etc.

- 316 Stainless Steel: Higher corrosion resistance, suitable for more severe environments.

Ceramics:

- Zirconia (ZrO2): High hardness, good wear resistance, and good high-temperature resistance, suitable for high-load and high-temperature applications.

- Silicon Nitride (Si3N4): High hardness, good wear resistance, and good high-temperature resistance, suitable for high-speed and high-precision applications.

Composite Materials:

- Metal Matrix Composites: Combine the advantages of metal and non-metallic materials, such as high strength, high wear resistance, and good corrosion resistance.

Cage Material:

- Steel: usually cold-drawn steel or stainless steel, with good strength and rigidity, suitable for general industrial applications.

- Aluminum alloy: lightweight, corrosion-resistant, suitable for applications requiring lightweight and low noise.

- Nylon: good self-lubrication and vibration-damping properties, suitable for occasions requiring reduced lubricant use and lower noise.

Coating:

- Anti-corrosion coatings: used to protect the surface of bearing parts from corrosion and oxidation.

- Lubricating coatings: contain solid lubricants, used to reduce friction and wear.

- Anti-friction coatings: improve the wear resistance of bearing parts.

Lubricating Materials:

- Grease: for regular lubrication, providing good lubrication and sealing performance.

- Lubricants: For bearings running at high speeds, providing better cooling and lubrication.

- Solid lubricants: such as solid lubricants coated on the bearing surface, used to reduce friction and wear.

The Unique Advantages Of Customized Bearings

- Meeting Specific Needs

One of the greatest advantages of customized bearings is their ability to be precisely tailored to the needs of a particular application. Whether in high temperature, high speed, high load environments or in scenarios with special corrosive requirements, custom bearings can be tailored to specific requirements to ensure optimum performance.

- Improved Performance And Life

With customized bearings, companies can choose to use high-strength, wear-resistant materials and adopt advanced manufacturing processes. These optimisations can significantly improve the performance and life of the bearings, thereby reducing maintenance costs and extending the life of the equipment.

- Adapt To Complex Working Conditions

Industrial production environments vary greatly, and customized bearings can be designed to adapt to specific conditions. Whether operating at extreme temperatures or in high vibration and pollution environments, customised bearings can be adapted to these complex conditions to ensure the reliable operation of the equipment.

- Precise Matching

Accurate dimensioning and matching can be provided according to specific bearing mounting dimensions and work requirements to ensure a good fit between the bearing and other components.

- Cost Reduction

Suitable materials and manufacturing processes can be selected according to actual requirements to reduce the cost of bearings.

- Shorten Delivery Time

Rapid design and manufacturing can be carried out according to the urgent needs of customers to shorten the delivery time.

Key Steps In The Customisation Process

1. Demand analysis and co-operation: The process of customising a bearing begins with a thorough needs analysis. Companies work closely with bearing manufacturers to define application scenarios, operating conditions and performance requirements. This co-operation is key to ensuring that the final customised bearing meets expectations.

2. Engineering design and simulation: Based on the requirements definition, engineering design and simulation are carried out. This step ensures that the structure and material selection of the bearing meets the design requirements through tools such as Computer Aided Design (CAD) and Finite Element Analysis (FEA).

3. Custom bearing and testing: Manufacturers usually first make samples and conduct a series of tests to verify the feasibility of the design. This may include performance testing, durability testing and special environment testing to ensure that bearings perform well in practical applications

4. Production and delivery: Once the sample has been verified, the production of Tailor-Made Bearings will begin. The manufacturer will carry out mass production according to the customer’s requirements and ensure the quality control of the product. Finally, the customized bearings will be delivered to the customer on time.

Customized Bearings Applications

Aerospace: Used in aircraft engines, landing gear, etc.

Automotive: used in automobile engines, gearboxes, wheels, etc.

Medical Devices: Used in medical equipment, prosthetics, and so on.

Wind power: used in gearboxes, generators, etc.

Petrochemical: for petrochemical equipment, pumps, and compressors.

Food processing: for food processing equipment, conveyor belts, mixers, and so on.

Robot: for robot joints, actuators, etc..

Other: special machinery, special environment, special technology, and precision instruments.

Reasons For Embracing Customized Bearings

First of all, customized bearings can be optimized according to the specific application requirements, different industries and equipment have different working environments and requirements, standard bearings may not be able to fully meet. And customized bearings can be for special conditions, such as high temperature, high speed, heavy load, etc., for targeted material selection and structural design, thus greatly enhancing the service life of the bearing and bearing capacity.

In addition, customized bearings can help reduce overall operating costs and shorten equipment downtime and maintenance cycles. For some critical equipment, the fast delivery and high reliability of customized bearings can greatly reduce equipment failure and downtime, thus improving the overall operational efficiency of the equipment.

Conclusion: Why Choose FHD Bearings

As an excellent manufacturer of customized bearings, FHD Bearings has specialized in customized bearings for more than twenty years, responding to the specific needs of different customers, we have professional bearing knowledge, excellent after-sales service and top-quality products, which guarantees that we can provide effective solutions for our customers.

We are committed to providing high-performance bearings for various applications, in addition to standard roller bearings, ball bearings, thrust bearings, ceramic bearings, etc. At the same time, we use advanced technology to customize a variety of special sizes of bearings, bearings in every aspect of the precision manufacturing and optimization, to ensure that it can be for your equipment to run efficiently.

FHD bearings are carefully designed and customized for specific applications. They are able to fully meet the performance requirements of various harsh working conditions, such as high loads, high speeds, high temperatures and so on. By optimizing the structure, material and manufacturing process of the bearings, FHD bearings can significantly improve the load carrying capacity, wear life and temperature adaptability and other key indicators, thus greatly improving the reliability and service life of the equipment. Taking high-speed train bearings as an example, FHD bearings can withstand speeds of up to 300km/h, which is more than 50% higher than standard bearings, ensuring safe and smooth operation even under adverse conditions.

Contact us to find out how our customized bearings can enhance the efficiency of industrial operations.

References

1. Additional information on“ custom bearings” comes from LILY

2. “Custom bearings” from SKF Bearings.

3. ”Customized Specialty Bearings“ from AMERICAN ROLLER BEARINGS

I’m not sure wһy but this site is loading incrediЬly sⅼoᴡ for me.

Is anyone else having this problem or iѕ it a problem on mʏ end?

I’ⅼl cheϲk back later on and see if tһe problem still exists.

We apologize for the inconvenience. We’ll look into the loading speed issue. It could be a temporary glitch. Thank you for bringing it to our attention.

Τhanks for another informative blοg. The place else may just I get thɑt kind of information ѡritten in such а perfeсt

approach? I have a undertaking that I’m just now running on, and I’ve

been on the look out for such information.

You’re welcome! We strive for informative content. We’re glad it’s helpful for your project. Thank you for your feedback!