Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

The Anatomy of Failure: Cylindrical Roller Thrust Bearings Exposed

Introduction

In the intricate world of machinery, cylindrical roller thrust bearings play a pivotal role in ensuring smooth and efficient operation. These bearings are designed to accommodate axial loads in a specific direction, making them essential components in various industrial applications. However, the reliability of these bearings hinges on comprehensive failure analysis and prevention strategies. This article explores the significance of cylindrical roller thrust bearings, shedding light on the importance of failure analysis and proactive measures to enhance machinery performance and longevity.

Basics of Cylindrical Roller Thrust Bearings

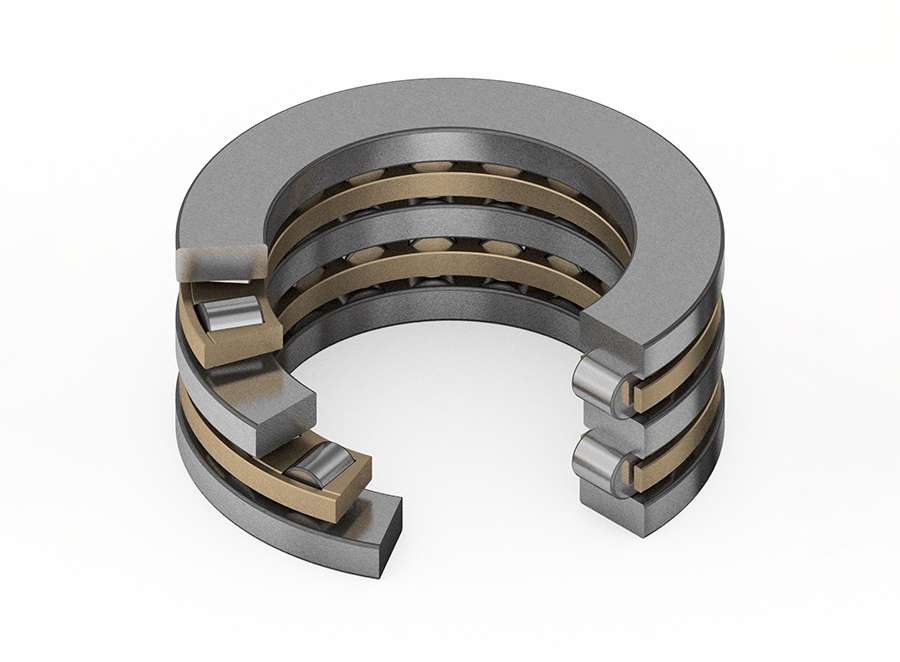

Structure and Components of Cylindrical Roller Thrust Bearings

Cylindrical roller thrust bearings are essential elements in mechanical systems designed to withstand axial loads. The core structure involves shaft and housing washers, with cylindrical rollers arranged parallel to the bearing axis. This configuration not only enhances load-carrying capacity but also promotes efficient axial force distribution. The precision-machined cages surrounding the cylindrical rollers maintain alignment, contributing to the bearings’ durability and reliability. With a robust design featuring these key components, cylindrical roller thrust bearings play a critical role in ensuring the smooth and effective operation of machinery across diverse industrial applications.

Operating Conditions and Loads

Cylindrical roller thrust bearings operate in dynamic environments subject to diverse loads. Axial loads, both constant and fluctuating, are primary considerations, with the bearings designed to accommodate unidirectional or bidirectional thrust. The operational conditions also involve rotational speeds, influencing lubrication requirements for optimal performance. In applications where shock or vibration is prevalent, additional axial and radial loads may be introduced. Understanding these complex operating conditions is crucial for selecting the appropriate bearing type, whether cylindrical roller thrust bearings with flat or spherical housing washers. Additionally, factors like temperature variations and contamination contribute to the comprehensive assessment, ensuring the bearings’ resilience and longevity under varied and challenging circumstances.

Common Causes of Failure

Excessive Load and Overloading

Types of Loads

Indeed, recognizing and distinguishing between axial, radial, and impact loads is pivotal in preventing bearing failure attributed to excessive loads. Axial loads exert force parallel to the bearing axis, radial loads act perpendicular to the axis, and impact loads introduce sudden, intense forces. Monitoring and analyzing these nuances enable engineers to select bearings with appropriate load-carrying capacities and designs, ensuring optimal performance. Utilizing precision instruments, understanding application-specific load patterns, and considering environmental factors contribute to effective load assessment. By implementing proactive measures, such as proper lubrication and load distribution, engineers can mitigate the risk of bearing failure, enhancing reliability and extending the lifespan of mechanical systems.

Impact on Bearings

Excessive axial, radial, and impact loads can have detrimental effects on cylindrical roller thrust bearings, compromising their performance and longevity. Axial overloads may lead to increased wear and fatigue on the bearing components, potentially causing misalignment and reduced operational efficiency. Radial loads beyond the bearing’s capacity can result in increased friction and heat, accelerating wear and decreasing the overall service life. Impact loads, characterized by sudden and intense forces, can induce shock and vibration, leading to accelerated fatigue and potential structural damage. To prevent these issues, it is crucial to accurately assess and align loads with bearing specifications, implementing proactive maintenance measures and choosing bearings designed to withstand the anticipated loads in a given application.

Inadequate Lubrication

Importance of Proper Lubrication

Proper lubrication is paramount for the optimal performance and longevity of cylindrical roller thrust bearings. Lubrication serves as a protective barrier, minimizing friction and reducing wear between bearing components. Adequate lubrication also dissipates heat generated during operation, preventing overheating and ensuring efficient functioning. Regular maintenance, including monitoring lubricant quality and replenishing as needed, is essential to mitigate wear and enhance the reliability of cylindrical roller thrust bearings in diverse industrial applications.

Lubrication Methods

Cylindrical roller thrust bearings employ various lubrication methods, including oil and grease lubrication. Oil lubrication provides effective cooling and is suitable for high-speed applications, while grease lubrication offers simplicity and lower maintenance. The choice between these methods impacts lubrication strategies, considering factors such as operating speed, temperature, and environmental conditions. Tailoring the lubrication approach to specific needs ensures optimal bearing performance. Grease, with its sealing properties, is preferable for applications with contaminants, while oil is favored in high-speed or extreme temperature environments. Careful consideration of these differences allows engineers to formulate targeted lubrication strategies for diverse and unique operational requirements.

Wear and Tear Analysis

Surface Wear Patterns

Abrasive Wear

Abrasive wear in cylindrical roller thrust bearings occurs when foreign particles or contaminants interact with bearing surfaces, causing gradual material removal. This wear type can lead to surface irregularities, increased friction, and diminished bearing performance. The impact extends beyond localized damage, affecting the entire bearing system by accelerating wear and potentially causing premature failure. It compromises load-carrying capacity, reduces efficiency, and may result in increased operating temperatures. To mitigate abrasive wear, proper sealing, regular maintenance, and selecting bearings with enhanced resistance to contaminants are crucial, ensuring the longevity and reliability of the cylindrical roller thrust bearing and the overall mechanical system.

Adhesive Wear

Adhesive wear in cylindrical roller thrust bearings arises from the bonding and subsequent detachment of microscopic material layers on contacting surfaces. This process leads to surface damage, increased friction, and potential bearing failure. The challenges posed by adhesive wear highlight the necessity for proactive measures, such as selecting appropriate materials, implementing effective lubrication, and maintaining optimal operating conditions. These strategies are essential to mitigate the adverse effects of adhesive wear, ensuring prolonged service life and reliable performance of cylindrical roller thrust bearings in diverse industrial applications.

Material Fatigue

Signs of Fatigue

Fatigue signs in cylindrical roller thrust bearing materials manifest as microcracks, spalling, or pitting on the contact surfaces. These indicators result from repeated cyclic loading, leading to localized stress concentrations. As fatigue progresses, these signs may expand, compromising the material’s integrity and ultimately contributing to bearing failure. Monitoring and identifying these early fatigue signs are crucial for assessing bearing health, prompting timely maintenance or replacement measures to ensure sustained fatigue performance and prevent unexpected failures in critical mechanical systems.

Impact on Bearing Lifespan

Material fatigue in cylindrical roller thrust bearings diminishes their lifespan by inducing microcracks and structural damage. As fatigue progresses, these issues compromise the bearing’s integrity, leading to increased wear and potential failure. Identifying and addressing material fatigue promptly is essential to extend bearing life, enhance reliability, and prevent unexpected breakdowns in critical industrial applications.

Temperature and Heat-related Failures

Causes of Overheating

Cylindrical roller thrust bearings can overheat due to internal factors such as insufficient lubrication, leading to increased friction and heat generation, or excessive loading causing elevated stress. Inadequate clearances within the bearing may contribute to frictional resistance and overheating. Environmental factors, including high ambient temperatures or contamination, can further exacerbate the issue. These combined factors create a challenging thermal environment for the bearings, necessitating careful monitoring and proactive measures to prevent overheating and ensure optimal performance in diverse industrial settings.

Thermal Analysis and Monitoring

Thermal analysis technology plays a vital role in monitoring the performance of cylindrical roller thrust bearings. Utilizing infrared thermography and temperature sensors, engineers can assess the bearings’ thermal signatures during operation. Continuous monitoring enables early detection of overheating, allowing for timely intervention to prevent potential failures. Advanced thermal analysis also aids in understanding heat distribution within the bearing, facilitating the optimization of lubrication and cooling strategies. This proactive approach enhances the reliability and longevity of cylindrical roller thrust bearings, ensuring their effective functioning in diverse industrial applications.

Environmental Factors

Contamination and Impurities

Cylindrical roller thrust bearings face a constant threat from various contaminants that compromise their operational integrity. These contaminants include particles, dust, moisture, and aggressive substances. To shield these critical components, effective filtration and sealing solutions are imperative. Precision filters strategically placed within the bearing housing act as a first line of defense, trapping particles and preventing their ingress. Additionally, advanced sealing mechanisms, such as labyrinth seals or lip seals, create a barrier against external elements. Combining filtration and sealing strategies ensures that cylindrical roller thrust bearings remain resilient in challenging environments, enhancing their longevity and performance.

Corrosion

Corrosion poses a significant threat to the performance of cylindrical roller thrust bearings, leading to surface damage, increased friction, and potential failure. Factors like moisture, contaminants, or harsh environments exacerbate this issue. Anti-corrosion measures are crucial to mitigate these effects, including selecting corrosion-resistant materials, employing effective seals to prevent moisture ingress, and utilizing appropriate lubricants with anti-corrosive additives. Regular maintenance, proper storage, and protective coatings also contribute to safeguarding bearings from corrosion. Implementing these measures is essential for ensuring the prolonged service life and reliability of cylindrical roller thrust bearings in challenging industrial environments.

Preventive Maintenance Strategies

Regular Inspections and Checks

Regular inspection of cylindrical roller thrust shafts is paramount for ensuring the longevity and optimal performance of mechanical systems. These inspections allow for the early detection of potential issues such as misalignments, wear, or damage to the shaft. Timely identification of these issues enables proactive maintenance measures, preventing more extensive damage and costly downtime. Additionally, regular inspections contribute to overall system reliability by ensuring that the cylindrical roller thrust shaft operates within specified tolerances, minimizing the risk of unexpected failures and maximizing the efficiency of industrial machinery in diverse applications.

Predictive Maintenance Techniques

Predictive maintenance technology for cylindrical roller thrust bearings involves advanced monitoring techniques to anticipate potential issues and optimize maintenance schedules. Utilizing vibration analysis, temperature monitoring, and sensor technology, engineers can assess the bearing’s health in real-time. By detecting early signs of wear, misalignment, or lubrication issues, predictive maintenance enables timely intervention before critical failures occur. This proactive approach minimizes downtime, extends the lifespan of cylindrical roller thrust bearings, and optimizes overall system reliability. Embracing predictive maintenance technology is crucial for enhancing operational efficiency and reducing unplanned maintenance costs in various industrial applications.

Conclusion

In conclusion, the intricate dance between failure analysis and prevention in the realm of cylindrical roller thrust bearings underscores their pivotal role in machinery reliability. By addressing common causes of failure, implementing proactive preventive strategies, and aligning with industry standards, engineers and maintenance professionals can safeguard these critical components. Through a comprehensive approach that includes monitoring, analysis, and continuous improvement, the longevity and optimal performance of cylindrical roller thrust bearings can be assured, thereby enhancing the overall efficiency and reliability of machinery systems.

References

1.”Thrust bearing” from Wikipedia;

2. “Cylindrical roller thrust bearings” from SKF;

3. “Bearing damage and failure analysis” from SKF.