Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

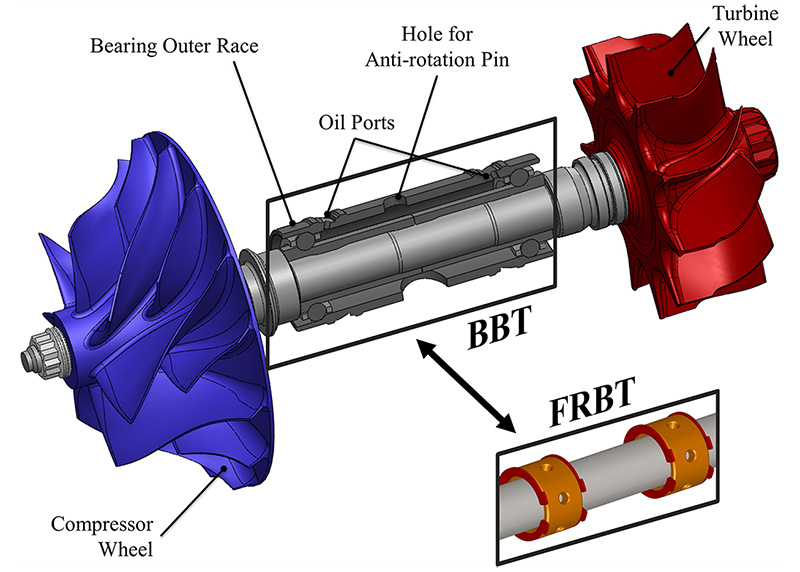

Reliability Testing and Validation of Turbocharger Bearings: Ensuring Performance Under Extreme Conditions

Introduction

Need for Rigorous Testing and Validation

The need for rigorous testing and validation in turbocharger bearings is paramount due to the critical role these components play in engine performance. Turbochargers operate under extreme conditions of high temperatures, speeds, and loads, making reliability a top priority. Without thorough testing, the risk of premature failure, reduced efficiency, and potential safety hazards increases significantly. Rigorous validation processes ensure that turbocharger bearings meet stringent performance standards and can withstand diverse operating conditions. This approach not only enhances reliability and durability but also instills confidence in the overall functionality of turbocharged engines.

Overview of Testing Processes

These processes include bench testing, accelerated life testing (ALT), field trials, and material testing. Bench testing involves assessing individual components and complete systems to evaluate load capacity, friction characteristics, and lubrication efficiency. Accelerated life testing subjects bearings to extreme conditions, simulating real-world scenarios to predict longevity and detect potential issues early on. Field trials validate performance in actual operating environments, providing valuable data for further improvements. Material testing ensures the selection of robust materials capable of withstanding high temperatures, corrosion, and wear. Collectively, these testing processes form a rigorous framework to ensure the reliability and durability of turbocharger bearings under diverse conditions.

Bench Testing

Purpose and Methodology

Bench testing serves as a crucial initial step in evaluating the performance and reliability of turbocharger bearings. The primary purpose of bench testing is to subject bearings to controlled conditions, both at the component and system levels, to assess various parameters critical to their operation. Methodologically, this involves mounting bearings in specialized test rigs and subjecting them to simulated loads, speeds, and operating conditions. Component-level testing focuses on evaluating specific characteristics such as load capacity, friction behavior, and lubrication efficiency, while system-level testing assesses the overall performance under realistic conditions. By meticulously examining these factors, bench testing provides valuable insights into the behavior of turbocharger bearings, enabling engineers to optimize design, identify potential issues, and ensure the bearings meet the stringent requirements for reliability and durability.

Parameters Tested

Bench testing involves a thorough evaluation of turbocharger bearings, scrutinizing several key parameters crucial to their performance and reliability. One essential parameter assessed during bench testing is load capacity, which determines the maximum force the bearing can withstand before failure. This examination helps engineers understand the bearing’s structural integrity and its ability to support the loads encountered during operation. Additionally, friction characteristics are meticulously analyzed to assess how efficiently the bearing operates under varying conditions. This evaluation includes examining factors such as friction coefficient, torque characteristics, and wear patterns, providing insights into the bearing’s efficiency and potential areas for improvement. Furthermore, lubrication efficiency is a critical parameter tested during bench testing, ensuring that the bearing receives adequate lubrication to minimize friction, reduce wear, and prolong its service life. By rigorously evaluating these parameters, bench testing enables engineers to optimize the design and performance of turbocharger bearings, ensuring reliability and durability under diverse operating conditions.

Accelerated Life Testing (ALT)

Significance in Reliability Assessment

Accelerated Life Testing (ALT) holds immense significance in the reliability assessment of turbocharger bearings, offering a comprehensive evaluation of their performance under extreme conditions. By subjecting bearings to accelerated stress levels and harsh operating conditions beyond what they would typically encounter in real-world scenarios, ALT simulates years of use in a condensed timeframe. This approach allows engineers to identify potential failure modes, predict longevity, and assess the bearing’s robustness under diverse operating conditions. ALT serves as a crucial tool for reliability assessment, enabling manufacturers to detect weaknesses early in the design phase, refine materials and lubricants, and optimize bearing geometry to enhance durability and performance. Ultimately, ALT provides invaluable insights into the long-term reliability of turbocharger bearings, ensuring they meet the stringent requirements for durability and performance in real-world applications.

Testing Environments

Accelerated Life Testing (ALT) involves subjecting turbocharger bearings to rigorous testing environments designed to simulate extreme operating conditions encountered in real-world scenarios. These testing environments typically include high-speed rotational testing and thermal cycling tests. High-speed rotational testing mimics the continuous high-speed operation of turbocharger bearings, assessing their performance under intense rotational forces and speeds. Thermal cycling tests, on the other hand, replicate the extreme temperature fluctuations experienced during engine operation, ranging from extreme cold to intense heat cycles. By exposing bearings to these demanding environments, ALT provides manufacturers with valuable data on their durability, reliability, and performance under harsh conditions. This comprehensive assessment enables engineers to refine bearing designs, materials, and lubrication systems to ensure optimal performance and longevity in actual operating environments.

Monitoring and Analysis

During Accelerated Life Testing (ALT), monitoring and analysis play pivotal roles in assessing the performance and reliability of turbocharger bearings under extreme conditions. Through continuous monitoring, engineers gather data on various parameters such as vibration levels, temperature fluctuations, and wear patterns. Vibration analysis enables the detection of any irregularities or excessive vibrations that may indicate potential issues with bearing operation. Temperature monitoring provides insights into how bearings respond to thermal stress, allowing engineers to evaluate their thermal stability and performance under varying temperatures. Additionally, wear and tear analysis involves inspecting bearing surfaces for signs of degradation or damage, helping identify potential failure modes and areas for improvement. By meticulously analyzing these parameters throughout the testing process, engineers can gain valuable insights into the bearing’s behavior, identify potential weaknesses.

Field Trials

Real-World Validation

Field trials provide essential real-world validation for turbocharger bearings, allowing manufacturers to assess their performance and reliability under actual operating conditions. These trials involve installing the bearings in vehicles or machinery and subjecting them to diverse environments, loads, and speeds encountered during typical use. By conducting field trials in various applications, such as commercial vehicles, industrial equipment, and marine engines, manufacturers can gather valuable data on the bearings’ performance over extended periods. This data includes information on factors such as durability, wear rates, and overall functionality, providing insights that cannot be fully captured in laboratory settings. Field trials offer a unique opportunity to validate the findings from bench testing and accelerated life testing, ensuring that turbocharger bearings meet the stringent requirements for reliability and durability in real-world applications.

Data Collection and Feedback

In field trials, data collection and feedback mechanisms are integral components that provide valuable insights into the performance and reliability of turbocharger bearings in real-world environments. Throughout the trial period, sensors and monitoring equipment are employed to gather data on various parameters such as operating temperatures, vibration levels, and lubrication effectiveness. This data is continuously analyzed to assess the bearings’ performance, identify any potential issues or anomalies, and track their overall functionality over time. Additionally, feedback from field operators and end-users is collected to gather qualitative insights into the bearings’ performance, reliability, and durability under actual operating conditions. This feedback loop enables manufacturers to gain a comprehensive understanding of how the bearings perform in the field, identify areas for improvement, and make informed decisions to enhance their design and functionality.

Iterative Improvement

Field trials serve as a crucial stage for iterative improvement in the development of turbocharger bearings, allowing manufacturers to implement enhancements based on real-world feedback and performance data. Throughout the trial period, engineers closely monitor the bearings’ performance, collecting data on factors such as wear rates, durability, and overall functionality. This data is then analyzed to identify areas for improvement and opportunities to optimize the bearings’ design, materials, and lubrication systems. By incorporating feedback from field operators and end-users, manufacturers can iteratively refine the bearings, addressing any issues or weaknesses identified during the trial period. This iterative improvement process ensures that turbocharger bearings continue to evolve and meet the ever-changing demands of real-world applications, ultimately enhancing their reliability, durability, and performance.

Material Selection and Testing

The importance of material properties lies in their ability to withstand the extreme conditions encountered in turbocharger operation, including high temperatures, heavy loads, and corrosive environments. Materials must possess attributes such as high-temperature resistance, excellent fatigue strength, and superior wear resistance to ensure reliable performance over the bearing’s lifespan. Additionally, materials must be carefully selected to minimize friction and wear, optimize lubrication, and prevent premature failure.

To ensure the suitability of materials for turbocharger bearings, various material testing methods are employed to assess their performance under simulated operating conditions. Metallurgical analysis is utilized to evaluate the microstructure, composition, and mechanical properties of materials, providing insights into their strength, ductility, and heat resistance. Tribological testing assesses the materials’ friction and wear characteristics under specific conditions, helping determine their suitability for bearing applications. Through meticulous material selection and testing, manufacturers can identify the most suitable materials for turbocharger bearings, ensuring they meet the stringent requirements for reliability, durability, and performance in demanding operating environments.

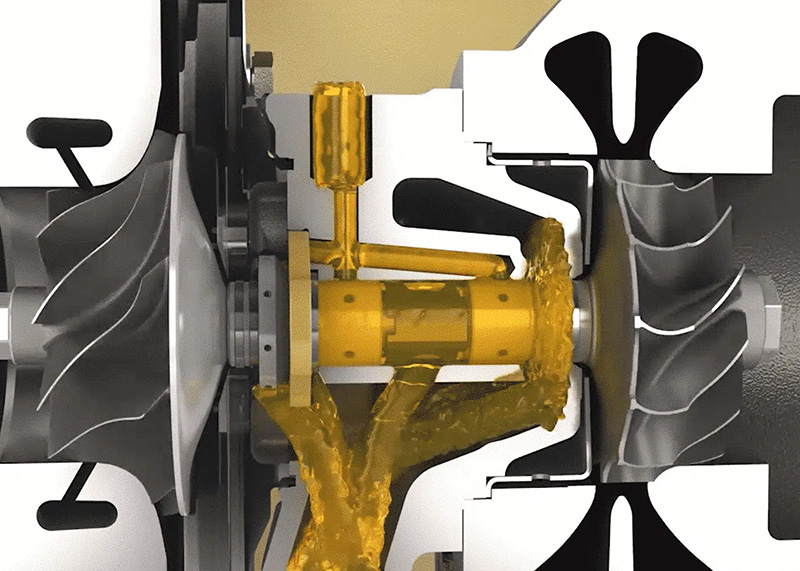

Thermal Management Testing

Thermal management testing is an essential aspect of turbocharger bearing development, aimed at addressing the challenges posed by high temperatures and their impact on bearing performance. Turbocharger bearings operate in environments with elevated temperatures due to their proximity to exhaust gases and the high-speed rotation of the turbocharger shaft. These extreme temperatures can lead to thermal expansion, degradation of lubricants, and thermal stresses on bearing components, potentially compromising their performance and longevity.

One approach in thermal management testing involves assessing the bearing’s thermal stability under high-temperature conditions, ensuring that it maintains its structural integrity and functionality without deformation or damage. Additionally, heat dissipation analysis is conducted to evaluate the effectiveness of cooling mechanisms in dissipating heat away from the bearing components, preventing overheating and thermal-related failures. By addressing the challenges posed by high temperatures through rigorous thermal management testing, manufacturers can optimize the design and materials of turbocharger bearings to withstand the demands of operating in extreme heat environments, ensuring reliable performance and longevity.

Environmental Testing

Environmental testing plays a vital role in assessing the performance and durability of turbocharger bearings under harsh conditions representative of real-world operating environments. This testing involves subjecting bearings to a variety of simulated environmental stressors, including exposure to dust, debris, humidity, and extreme temperatures. Dust and debris exposure testing evaluates the bearings’ ability to withstand abrasive particles and contaminants that can lead to premature wear and damage. Humidity and moisture testing assesses their resistance to corrosion and degradation in humid or wet conditions, which can compromise performance and longevity. Additionally, extreme temperature testing evaluates how bearings perform under temperature fluctuations, ensuring their ability to maintain functionality and structural integrity across a wide range of operating conditions. By subjecting turbocharger bearings to rigorous environmental testing, manufacturers can identify potential vulnerabilities and make necessary design improvements to enhance their reliability and performance in harsh operating environments.

Quality Control Measures

Quality control measures are integral to ensuring the consistency and reliability of turbocharger bearings. Throughout the manufacturing process, rigorous in-process inspections monitor parameters such as dimensions and surface finish, while statistical process control techniques analyze production data to maintain high standards. Non-destructive testing methods, like ultrasonic testing and magnetic particle inspection, assess bearing integrity without causing damage. These measures ensure that only bearings meeting stringent quality criteria proceed to further processing or assembly. By implementing robust quality control measures and non-destructive testing techniques, manufacturers uphold the highest standards of consistency and reliability, enhancing customer satisfaction and trust in their products.

Conclusion

In conclusion, the rigorous testing and validation of turbocharger bearings are imperative to ensure their reliability, durability, and performance under extreme operating conditions. Through processes such as bench testing, accelerated life testing, field trials, material testing, thermal management testing, environmental testing, and quality control measures, manufacturers can identify potential weaknesses, optimize designs, and enhance the overall functionality of turbocharger bearings. By employing a comprehensive testing framework, manufacturers can instill confidence in the reliability of turbocharged engines, ultimately leading to improved efficiency, reduced downtime, and enhanced safety in automotive and industrial applications.

References

- 1.”Development of high-heat-resistant ball bearing unit to meet various requirements” from MinebeaMitsumi;

- 2. “Turbocharger Bearings” from LILY Bearing;

- 3. “Ball bearing turbocharger vibration management” from Mechanics & Industry.