Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

How To Reduce The Downtime Of Water Pump Bearings In Your Application?

What Are Water Pump Bearings

Water pump bearings are sealed double-row bearings with wide spacing between the two rows of rolling elements.

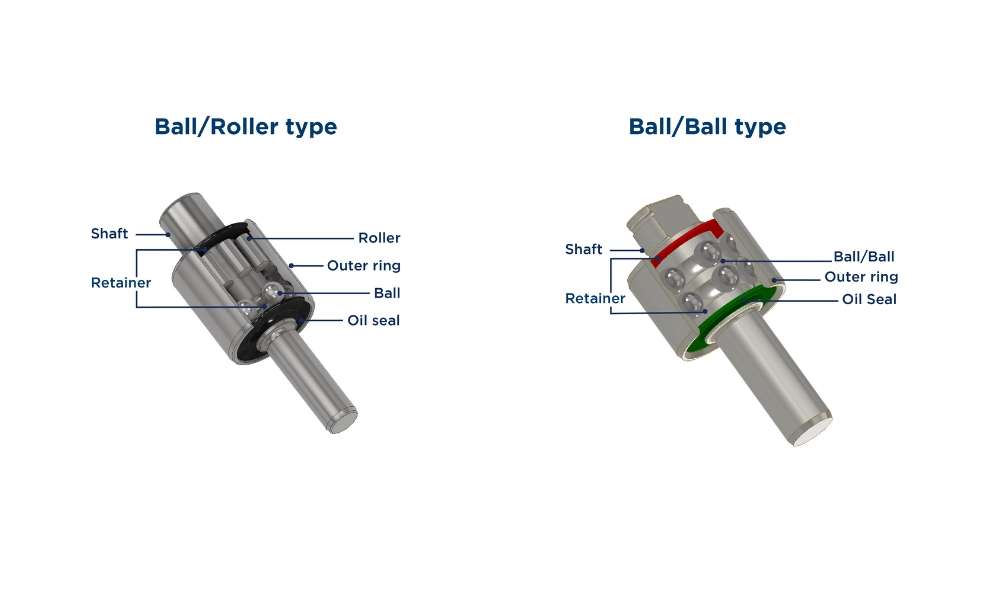

There is a ball-ball type consisting of only balls and a ball-roller type consisting of a ball and a roller.

Water pump bearings typically consist of several key components:

- Inner and Outer Rings: These rings provide structure and support to the bearing assembly. The inner ring is mounted on the pump shaft, while the outer ring is usually fixed inside the pump casing.

- Rolling elements: Bearings typically utilize rolling elements such as balls or rollers to reduce friction and support rotational motion. These rolling elements are located within the inner and outer rings and distribute the load evenly throughout the bearing assembly.

- Cage or Keeper: A cage or retainer secures the rolling elements, prevents them from rubbing against each other, and maintains proper spacing within the bearing assembly.

- Seals: Seals are critical to preventing water and contaminants from entering bearing assemblies, as exposure to these elements can cause premature bearing wear and failure. High-quality seals ensure long-term reliability and durability of water pump bearings.

How Do Water Pump Bearings Work?

Support and reduce friction , the main function of water pump bearings is to support the water pump shaft and reduce friction during rotation.

Rolling elements reduce friction , water pump bearings usually contain rolling elements inside, such as balls or rollers. These rolling elements create contact points between the shaft and the bearing and roll as the shaft rotates, thus reducing friction.

Cage maintains structural stability , bearings also usually have cages or keepers inside, which serve to keep the rolling elements in place and ensure that they remain properly spaced and positioned.

Seals prevent contamination and damage , water pump bearings are usually equipped with seals that are used to prevent external water, contaminants and particles from entering the inside of the bearing.

Understanding The Causes Of Water Pump Bearing Failure

Before we talk about reducing downtime, let’s understand the causes of water pump bearing failure. The problem can be solved only after the root cause is found.

Lack of Lubrication: One of the primary reasons for bearing failure in water pumps is a lack of proper lubrication. Insufficient or contaminated lubricant can lead to increased friction and wear on the bearings, ultimately causing them to fail prematurely.

Overloading: Excessive loads on the water pump bearings can also contribute to premature failure. Overloading can occur due to factors such as improper pump sizing, excessive pressure, or operating beyond the pump’s design limits.

Misalignment: Misalignment of the pump shaft can cause uneven loading on the bearings, leading to accelerated wear and potential failure. Proper alignment is essential to ensure the smooth operation of the pump and prevent bearing damage.

Contamination: Dust, dirt, and other contaminants can infiltrate the bearings and cause abrasive wear. Contamination can also lead to corrosion, which can further degrade the bearing surfaces and shorten their lifespan.

Improper Installation: Incorrect installation practices, such as improper mounting or inadequate tightening of fasteners, can put additional stress on the bearings and cause premature failure.

How To Reduce Downtime With Water Pump Bearings

Proper Lubrication

- One of the most important factors in ensuring the longevity of water pump bearings is proper lubrication. Bearings that are not adequately lubricated are more prone to wear and failure.

- It is important to regularly check the lubrication levels of the bearings and ensure that they are properly greased.

- Using the correct type and amount of lubricant is crucial in preventing premature bearing failure.

Regular Maintenance

- Regular maintenance is essential in preventing water pump bearing failure.

- This includes inspecting the bearings for signs of wear or damage, as well as checking for any unusual noises or vibrations coming from the pump.

- In addition, it is important to regularly clean the pump and bearings to remove any debris or dirt that could cause damage.

Proper Installation

- Proper installation of water pump bearings is also key in preventing downtime.

- It is important to ensure that the bearings are installed correctly and securely, and that they are aligned properly with the pump shaft.

- Improper installation can lead to premature wear and failure of the bearings.

Avoid Overloading

- Another common cause of water pump bearing failure is overloading.

- It is important to ensure that the pump is not being operated beyond its capacity, as this can put excessive strain on the bearings and lead to premature failure.

- Monitoring the pump’s performance and ensuring that it is operating within its recommended limits can help to prevent overloading and extend the life of the bearings.

Use High-Quality Bearings

- Using high-quality bearings is essential in reducing downtime and prolonging the life of water pump bearings.

- While high-quality bearings may come at a higher cost initially, they can ultimately save money in the long run by reducing downtime and repair costs.

What Are The Applications Of Water Pump Bearings

Water pump bearings are key components in the water pump system, providing support for the water pump shaft and promoting its smooth rotation. These bearings are specifically designed to withstand the harsh conditions of water pump operation, including high speeds, varying temperatures, and exposure to water and contaminants. Applications for water pump bearings include:

Water treatment industry: Water pump bearings are widely used in water treatment equipment, such as sewage treatment plants, tap water treatment plants, sewage pumping stations, etc., for transporting, lifting and treating various water sources.

Construction engineering: In construction engineering, water pump bearings are used in building drainage systems, water supply systems, fire protection systems, etc. to ensure smooth water supply and drainage inside and outside the building.

Agricultural irrigation: Agricultural irrigation systems require a large number of water pumps to deliver water to the fields. Water pump bearings play an important role in these pumps to ensure the normal operation of the irrigation system.

Mining and mining: In the mining and mining industry, water pump bearings are used in a variety of applications such as pumping groundwater, drainage, transporting slurries, and treating wastewater, ensuring the normal operation and safe production of mining equipment.

Energy industry: In the process of energy production and transmission, water pump bearings are used in coal-fired power plants, nuclear power plants, hydropower plants and other equipment to ensure the stable operation of cooling systems, water supply systems and circulation systems.

Ship and marine engineering: In the field of ship and marine engineering, water pump bearings are widely used in water supply systems, cooling systems, sewage treatment systems, etc. of ships to ensure the normal operation of ship equipment.

Manufacturing and processing industries: In manufacturing and processing industries, water pump bearings are used in processing equipment, machine tools, cooling systems, lubrication systems, etc. to ensure the normal operation and production efficiency of equipment.

Construction equipment: In construction equipment, water pump bearings are used in concrete mixer trucks, pump trucks, compressors and other equipment to provide the necessary water source and pressure.

What Are The Advantages Of Using Quality Water Pump Bearings

Water pump bearings have several advantages, including:

- Improved performance: Quality water pump bearings can improve the overall performance of the water pump, leading to better efficiency and reliability.

- Increased durability: High-quality bearings are made from durable materials that can withstand high temperatures, pressure, and corrosion, resulting in a longer lifespan for the water pump.

- Reduced maintenance: With quality bearings, there is less need for frequent maintenance and replacement, saving time and money in the long run.

- Smooth operation: Quality bearings provide smooth and quiet operation, reducing noise and vibration in the water pump system.

- Better seal protection: Quality bearings often come with better seal protection, preventing water leakage and contamination in the pump system.

- Higher resistance to wear and tear: Quality water pump bearings are designed to withstand wear and tear, ensuring consistent performance over time.

- Improved efficiency: By reducing friction and heat generation, quality bearings can improve the overall efficiency of the water pump, leading to lower energy consumption.

Conclusion

To reduce water pump bearing downtime in your application, it is essential to prioritize regular maintenance and monitoring of the bearings.

This includes inspecting for wear and tear, lubricating the bearings as needed, and replacing them before they fail.

Implementing a proactive maintenance schedule can help prevent unexpected downtime and extend the lifespan of the bearings.

Additionally, selecting high-quality bearings that are designed for the specific demands of the application can also help minimize downtime.

Proper installation of the bearings, ensuring they are properly aligned and balanced, is crucial for optimal performance and longevity.

Monitoring the temperature and vibration of the bearings can also provide early warning signs of potential issues, allowing for timely intervention before a failure occurs.

By investing in proper maintenance, monitoring, and quality bearings, you can reduce downtime and ensure the smooth operation of your water pump system.

References

- 1.About “water pump bearings ”from JTEKT Company

- 2. About the Detailed Introduction Of What Is “Water Pump Bearings” And Seals