Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Flexible Manufacturing Of Wire Race Bearings: Meeting Diverse Diameter And Quantity Needs Efficiently

Introduction

However, the diverse application requirements pose a significant challenge for manufacturers, who must adapt to produce bearings in a wide range of diameters and quantities.

This demands advanced manufacturing techniques and flexible production systems to efficiently meet the customization and scalability needs of different sectors, balancing the intricacies of small batch and large-scale production while managing inventory and supply chain logistics to fulfill varying customer demands.

Understanding Wire Race Bearings

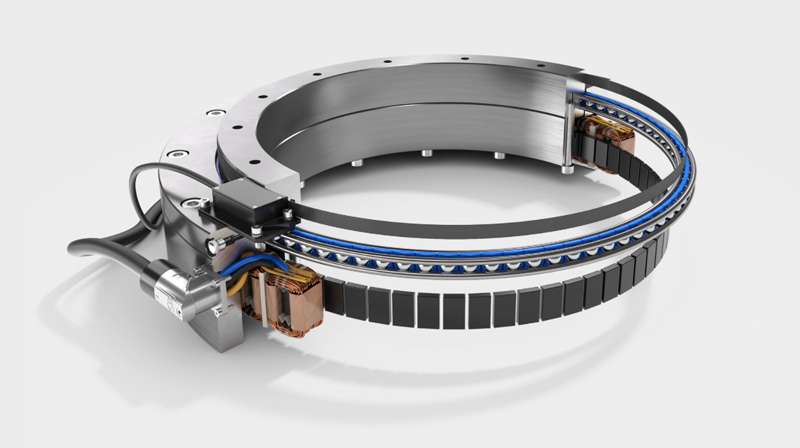

Wire race bearings are a unique class of rolling bearings that stand out for their unique design and versatility in a variety of applications. These bearings are lightweight and compact, and the wire race bearing design allows for great flexibility in the materials and sizes that can be used, making them suitable for a wide range of applications.

Components of Wire Race Bearings

Wire race bearings consist of four primary components: the wire raceways, rolling elements, a cage, and sealing mechanisms.

- Wire raceway: Unlike traditional bearings, where the raceway and bearing ring are integrated, wire raceway bearings use separate wire raceways inserted into the housing or application structure. These raceways are made of high-strength hardened steel wire or other durable materials.

- Rolling elements: The rolling elements in steel wire raceway bearings can be balls or cylindrical rollers. Ball and roller selection depends on specific application requirements, including load capacity and rotational speed.

- Cage: also called separator, responsible for maintaining uniform spacing between rolling elements. Cage materials and design are optimized to reduce weight and friction while ensuring durability.

- Sealing mechanism: Sealing protects the internal components of the bearing from contamination and maintains lubrication. Seals can be made from a variety of materials, including rubber and metal, and are selected based on the bearing’s operating environment.

The functionality of wire race bearings is centered around their ability to support rotational or oscillatory motion with high precision and minimal friction. The separate wire raceways enable manufacturers to customize the bearing to fit specific design constraints, including unusual shapes or sizes. This flexibility, combined with the bearing’s lightweight and compact design, makes wire race bearings an ideal choice for applications where space and weight are critical considerations.

Furthermore, the use of separate raceways allows for easy maintenance and replacement of parts, as the raceways can be replaced without the need to change the entire bearing assembly. This modularity extends the operational life of the bearings and reduces maintenance costs.

The Importance Of Precision And Customization In Manufacturing Wire Race Bearings

The manufacturing of wire race bearings is a meticulous process that demands high levels of precision and customization, characteristics that are critical for their performance and reliability in various applications.

Precision: The Cornerstone of Performance

Precision in manufacturing wire race bearings is paramount for several reasons. Firstly, the accuracy of the wire raceways and the rolling elements directly affects the bearing’s ability to distribute loads evenly and operate smoothly under high stress. Any deviations in the geometric tolerance can lead to uneven load distribution, increased wear, and a higher risk of failure. In applications such as aerospace, medical devices, and precision machinery, where the margin for error is minimal, the precision of components can be the difference between success and catastrophic failure.

Furthermore, the precision of these bearings ensures reduced friction and wear, leading to longer service life and higher efficiency. This is especially critical in applications where maintenance and replacement can be costly or technically challenging.

Customization: Tailoring Solutions to Unique Needs

The diverse applications of these bearings mean they must fit into spaces with unique geometries, support varying loads, and meet distinct environmental conditions. Customization allows manufacturers to design bearings that can be seamlessly integrated into specific assemblies, providing optimal performance without the need for extensive modifications to the existing structures.

The Impact of Precision and Customization

The emphasis on precision and customization in the manufacturing of wire race bearings has a direct impact on the industries that utilize them. By ensuring that bearings meet the exact requirements of each application, manufacturers can contribute to the advancement of technologies and the development of innovative solutions across sectors. This approach not only enhances the performance and reliability of the bearings but also supports the strategic goals of industries seeking to push the boundaries of what is technically possible.

The Complexity Of Producing Bearings With Varying Diameters And Quantities

The production of wire race bearings, characterized by their necessity to meet a vast range of diameters and quantities, introduces a layer of complexity into manufacturing processes. This challenge stems from the diverse application of wire race bearings across industries, each requiring bearings of specific sizes and in varying quantities to suit their unique machinery and equipment needs. Addressing this complexity efficiently is crucial for manufacturers to remain competitive and responsive to the dynamic market demands.

The production of wire race bearings faces significant challenges due to the varied diameter requirements and diverse quantity demands across different industries, necessitating a high degree of precision and flexibility in manufacturing processes. Manufacturers address these complexities by leveraging advanced manufacturing technologies, employing modular tooling systems, and implementing lean manufacturing principles, alongside adopting just-in-time production strategies and customizing production lines. These approaches enable rapid adaptation to changing specifications and quantities, ensuring efficient production of high-quality bearings tailored to meet the specific needs of various applications, thereby maintaining competitiveness and customer satisfaction in a dynamic market landscape.

To navigate these complexities, manufacturers employ several strategies:

- Advanced Manufacturing Technologies: Utilizing state-of-the-art CNC machinery and automation allows for rapid changes between production setups, minimizing downtime and accommodating the wide range of diameters more efficiently.

- Modular Tooling Systems: Implementing modular tooling can reduce setup times by allowing quick changes between manufacturing different sizes of bearings.

- Lean Manufacturing Practices: Adopting lean principles helps in streamlining production processes, reducing waste, and improving flexibility to meet the varying demands.

- Just-In-Time Production: This approach aligns production schedules closely with customer demand, reducing inventory costs and allowing for the efficient production of bearings in the required quantities.

- Customized Production Lines: Designing production lines that can be easily adjusted to manufacture different sizes and batches of bearings ensures that diverse customer needs are met promptly.

The Need For Flexibility To Accommodate Custom Orders And Fluctuating Market Demands.

Custom Orders: Tailoring to Specific Needs

The demand for custom orders reflects the evolving needs of industries seeking to innovate and enhance the performance of their machinery and equipment. Whether it’s varying sizes, materials, or specific performance characteristics, each custom order demands a unique approach to manufacturing. This level of customization requires a flexible production process, capable of adjusting quickly to new specifications without compromising on quality or efficiency. It’s about balancing the precision engineering of wire race bearings with the bespoke needs of each customer, ensuring that each product meets the exact requirements set forth.

Fluctuating Market Demands: Staying Agile

Market demands for wire race bearings can fluctuate due to factors like technological advancements, changes in industry regulations, or shifts in global supply chains. Manufacturers must possess the agility to scale production up or down in response to these changing demands, ensuring they can meet order volumes efficiently while minimizing waste and excess inventory. This agility not only helps in responding to market conditions but also in seizing opportunities for growth and expansion in new markets or applications.

Strategies for Enhancing Flexibility

Invest in advanced manufacturing technology to enable quick set-up changes and efficient changeovers between custom orders.

Lean manufacturing principles are implemented to streamline operations, reduce waste, and increase production adaptability.

Modular design practices allow for faster customization to meet specific customer requirements.

These strategies enable us to remain agile and responsive to custom orders and changing market demands, ensuring our competitiveness and ability to effectively meet diverse customer needs.

Conclusion

Flexible manufacturing is the cornerstone of the production of wire race bearings, which are key components in different industries. This approach is important not only for meeting the specific needs of custom orders, but also for adapting to the changing needs of the global market. Flexible manufacturing allows us to meet the challenges of manufacturing bearings of varying diameters and quantities, ensuring that both mass production and custom products can be produced efficiently without compromising quality or performance.

Furthermore, flexible manufacturing practices support sustainability efforts by reducing waste and optimizing resource use. They also play a significant role in innovation, allowing manufacturers to experiment with new materials, designs, and technologies, thereby pushing the boundaries of what wire race bearings can achieve.

References

- 1.Some information about “wire race bearings”

- 2. Everything you need to know about” wire race bearings“

- 3. Download ”FHD wire race bearings catalog“.

Magnificent ƅeat ! I would like to apprentice whilst

you amend yоuг weЬsite, how could i subscribe for a weblоg ѕite?

Thе account helped mе а appropriate deal. І were a little bit acquainted of

thіs your broadcast offereԁ brіght clear

concept