8 Signs You’re Getting the Best Value in Zinc Alloy Bearings

Characteristics of zinc alloy bearing

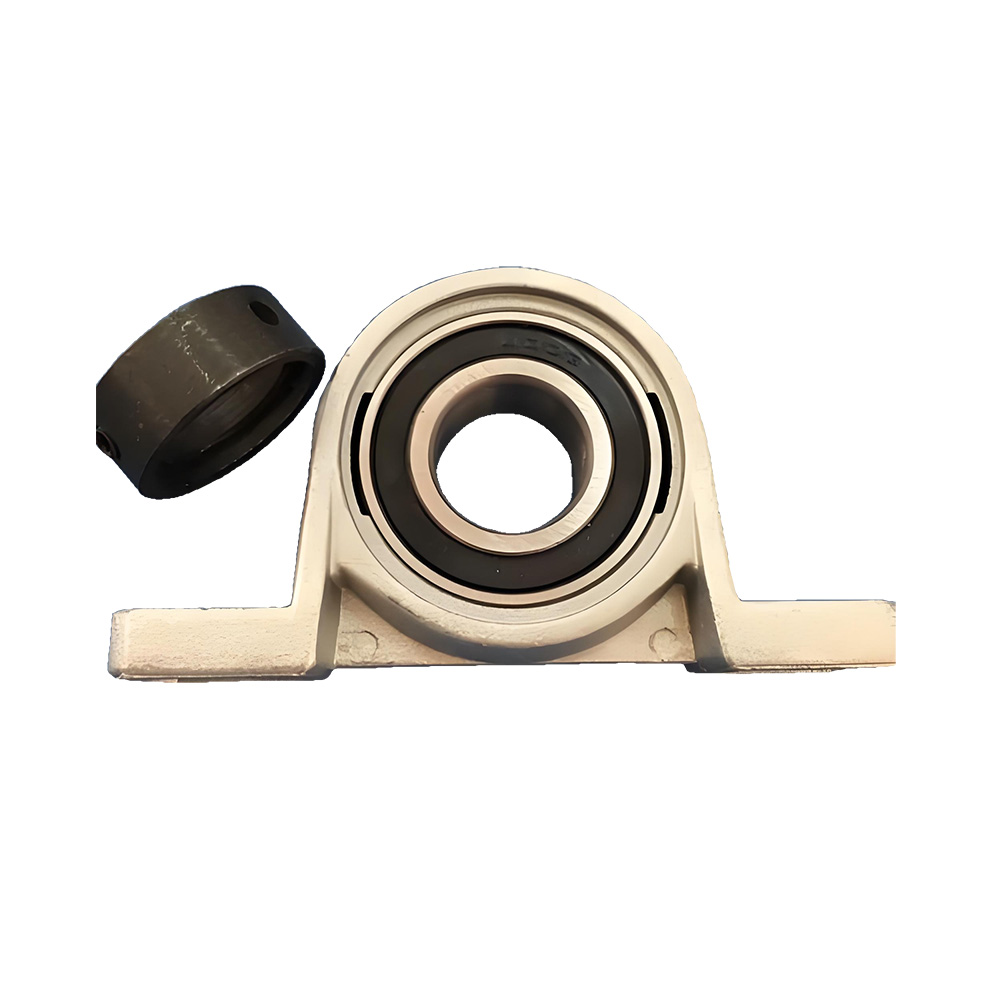

A zinc alloy bearing is a type of bearing made from zinc-based alloys, which typically include other metals such as aluminum, copper, and magnesium. These bearings are designed to support and reduce friction between moving parts in machinery, allowing for smooth operation. Zinc alloy bearings are known for their good wear resistance, corrosion resistance, and relatively low cost, making them suitable for various applications, including automotive, industrial, and consumer products.

Zinc alloy bearings are often used in situations where lightweight materials are required, and they can be manufactured with high precision. The specific properties of the alloy can be adjusted to meet different performance requirements, such as strength, hardness, and durability. These bearings are valued for their ability to perform well under moderate loads and in environments where moisture or other corrosive elements are present.

Zinc alloy bearing application field

1.Automotive Components:

- Steering Mechanisms: Zinc alloy bearings are often used in steering columns and linkages, where they help reduce friction and ensure smooth operation.

- Window Regulators: These bearings are used in the mechanisms that raise and lower vehicle windows.

- Wiper Motors: Zinc alloy bearings support the smooth movement of windshield wipers.

2.Industrial Equipment:

- Conveyor Systems: In light-duty conveyor systems, zinc alloy bearings help reduce friction between moving parts, ensuring efficient material handling.

- Electric Motors: Small electric motors, often found in various industrial applications, use zinc alloy bearings to reduce friction and extend the motor’s lifespan.

- Gearboxes: Zinc alloy bearings can be found in gearboxes where they help in the smooth transmission of power.

3.Home Appliances:

- Fans and Blowers: Zinc alloy bearings are used in the motors of fans and blowers, ensuring quiet and efficient operation.

- Kitchen Appliances: Small appliances like mixers, blenders, and food processors often incorporate zinc alloy bearings to support rotating components.

- Washing Machines: Bearings in washing machines may be made from zinc alloy to withstand the constant motion and exposure to water.

4.Consumer Electronics:

- Printers and Scanners: Zinc alloy bearings are used in the moving parts of printers and scanners to ensure precise and smooth operation.

- Hard Drives: In some cases, zinc alloy bearings are used in the rotating mechanisms of hard drives to reduce noise and wear.

5.Agricultural Machinery:

- Harvesters and Plows: Zinc alloy bearings can be found in various agricultural equipment, where they contribute to the reliability and longevity of the machinery under moderate loads.

6.Construction Equipment:

- Concrete Mixers: The rotating drum of a concrete mixer may utilize zinc alloy bearings to reduce friction and wear.

- Drilling Equipment: Some light-duty drilling equipment uses zinc alloy bearings to support the rotating drill bit and other moving parts.

Zinc alloy bearings are especially useful in applications where moderate loads and speeds are common, and where cost and corrosion resistance are important considerations.

Zinc Alloy Bearing: 8 Signs You’re Getting the Best Value

Solution 1: Comprehensive Material Quality

Rigorous Testing Procedures: A key indicator of value in zinc alloy bearings is the rigor with which the material quality is tested. Trusted manufacturers implement thorough testing procedures, ensuring that the raw materials used meet the highest standards. These tests typically involve checking for impurities, strength, and the consistency of the alloy mix, ensuring that the bearings will perform reliably in their intended applications.

Consistency in Alloy Composition: The composition of the zinc alloy is crucial in determining the bearing’s performance and durability. Consistent alloy composition ensures that each bearing produced will have the same quality and characteristics. This consistency is vital for brand procurement professionals who rely on predictable and reliable performance across all products.

Certification from Reputable Standards: Manufacturers who offer the best value often have certifications from recognized industry standards organizations. These certifications provide assurance that the zinc alloy bearings meet or exceed the stringent quality requirements set by the industry. Brands can confidently procure these certified products, knowing they have been validated by independent bodies.

Solution 2: Precision Manufacturing Process

Advanced CNC Machining Techniques: Precision in manufacturing is another sign of value when evaluating zinc alloy bearings. Advanced CNC machining techniques allow manufacturers to produce bearings with exceptional accuracy and uniformity. This precision is critical in applications where even the smallest deviation can impact performance.

Tight Tolerance Levels Maintained: Maintaining tight tolerances is essential for the proper functioning of zinc alloy bearings. Bearings that are manufactured with precise tolerances will fit better, reducing the likelihood of premature wear or failure. This attention to detail in the manufacturing process is a hallmark of a high-quality product.

Regular Calibration of Equipment: Ensuring that manufacturing equipment is regularly calibrated is key to maintaining the accuracy of the production process. Calibration prevents deviations that could lead to defects in the final product. Brands that procure from manufacturers who prioritize this aspect can expect a consistent and reliable supply of high-quality bearings.

Solution 3: Durability and Longevity

Resistance to Wear and Tear: Durability is a critical factor in determining the value of zinc alloy bearings. Bearings that resist wear and tear over time are more cost-effective, as they require less frequent replacement. This resilience is achieved through the careful selection of alloy components and precision manufacturing processes.

Effective Corrosion Protection: Zinc alloy bearings are often used in environments where they are exposed to moisture or chemicals. Effective corrosion protection is therefore essential to maintain their performance and extend their lifespan. Bearings that have been treated with corrosion-resistant coatings or produced from alloys with inherent corrosion resistance offer greater value to brands.

Verified Performance Under Stress: High-quality zinc alloy bearings are designed to perform reliably even under stressful conditions. This includes resistance to high loads, extreme temperatures, and constant motion. Verified performance under such conditions indicates that the bearings will hold up in demanding applications, providing long-term value to brands.

Solution 4: Cost-Effective Production

Efficient Supply Chain Management: A streamlined supply chain is essential for keeping production costs low while maintaining high quality. Manufacturers who have optimized their supply chain processes can produce zinc alloy bearings more efficiently, passing on cost savings to their customers. Efficient supply chain management also reduces the risk of delays, ensuring that products are delivered on time.

Bulk Production Capabilities: The ability to produce zinc alloy bearings in bulk is a significant advantage for manufacturers looking to offer cost-effective solutions. Bulk production allows for economies of scale, which can lower the per-unit cost of the bearings. Brands that require large quantities of bearings can benefit from these savings, making bulk production a key factor in evaluating value.

Competitive Pricing Strategies: Competitive pricing is a clear indicator of value, but it should not come at the expense of quality. Manufacturers who can offer attractive pricing while still delivering high-quality zinc alloy bearings demonstrate a strong commitment to providing value to their customers. Brands should look for manufacturers who strike the right balance between cost and quality.

Solution 5: Customization Options

Tailored Designs for Specific Applications: The ability to customize zinc alloy bearings to meet specific application requirements is a sign of value. Customization options may include altering the size, shape, or material composition of the bearings to better suit the intended use. Brands that need specialized bearings will find greater value in manufacturers who offer flexible design options.

Flexible Production Volumes: Not all brands require large quantities of bearings at once, so manufacturers who can accommodate both small and large production volumes provide significant value. This flexibility allows brands to procure the exact number of bearings they need without overcommitting resources. It also enables better inventory management, reducing waste and costs.

Adaptive Solutions for Unique Challenges: Manufacturers that can adapt their production processes to meet unique challenges faced by brands are invaluable partners. Whether it’s developing a bearing that performs in extreme conditions or creating a custom solution for a novel application, adaptive solutions demonstrate a manufacturer’s commitment to meeting customer needs. This adaptability is a strong indicator of value.

Solution 6: Reliable Supply Chain

Strong Relationships with Raw Material Suppliers: A reliable supply chain is built on strong relationships with raw material suppliers. Manufacturers who have established these relationships can ensure a steady supply of high-quality materials, reducing the risk of production delays. Brands benefit from this reliability, knowing that their orders will be fulfilled on time and with consistent quality.

On-Time Delivery Performance: Timely delivery is crucial for maintaining the smooth operation of a brand’s production process. Manufacturers with a track record of on-time delivery demonstrate their reliability and efficiency. Brands that partner with such manufacturers can avoid costly delays and disruptions in their own production schedules.

Transparent Logistics Management: Transparency in logistics management is essential for building trust between manufacturers and brands. Manufacturers who provide clear and accurate information about the status of shipments, potential delays, and delivery timelines offer greater value. This transparency allows brands to plan more effectively and manage their supply chains with confidence.

Solution 7: Compliance with Industry Standards

Adherence to International Quality Standards: Compliance with international quality standards is a fundamental indicator of value in zinc alloy bearings. Manufacturers who adhere to these standards ensure that their products meet the stringent requirements set by regulatory bodies. Brands that source from compliant manufacturers can be confident that the bearings will perform reliably and safely in their applications.

Regular Compliance Audits: Regular audits of compliance with industry standards are essential for maintaining the quality and safety of zinc alloy bearings. Manufacturers who undergo these audits demonstrate their commitment to continuous improvement and quality assurance. Brands can trust that these manufacturers are consistently meeting or exceeding the standards required for their products.

Ethical Manufacturing Practices: Ethical manufacturing practices, including fair labor conditions and environmentally sustainable processes, are increasingly important to brands and consumers alike. Manufacturers who prioritize these practices offer more than just a high-quality product; they offer a product that aligns with the values of responsible sourcing. Brands that procure from such manufacturers can enhance their own reputation and appeal to conscientious consumers.

Solution 8: Excellent Customer Support

Prompt Response to Inquiries: Excellent customer support begins with prompt and professional responses to inquiries. Manufacturers who prioritize customer communication ensure that brands receive the information they need in a timely manner. This responsiveness is crucial for maintaining strong relationships and ensuring that brands feel supported throughout the procurement process.

Technical Assistance and Guidance: Manufacturers who offer technical assistance and guidance provide added value to their customers. Whether it’s helping with the selection of the right bearing for a specific application or offering advice on installation and maintenance, this support can be invaluable. Brands benefit from the expertise of the manufacturer, which can help them make more informed decisions.

Post-Purchase Support and Warranty Services: The value of zinc alloy bearings extends beyond the point of sale, and manufacturers who offer robust post-purchase support and warranty services demonstrate their commitment to customer satisfaction. These services can include addressing any issues that arise after purchase, providing replacement parts, or offering extended warranties. Brands that have access to these services can be assured of long-term value and reliability in their investment.

References

Related Posts

Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)