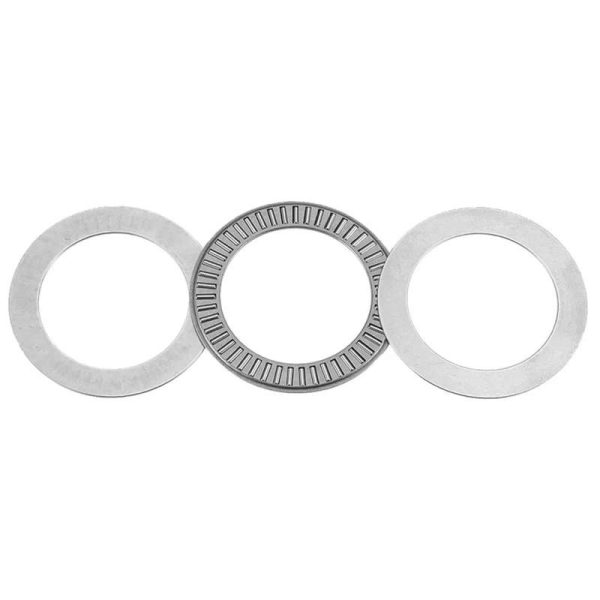

Needle Roller Thrust Bearings

Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (27)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Definition

Thrust needle roller bearings are specialized bearings designed to handle axial loads by using needle rollers with minimal radial dimensions, providing efficient and compact thrust load support in various applications.

FHD Bearings is an ISO 9001:2015 certified manufacturing enterprise that stsock a full range of Cylindrical Roller Bearings,Tapered Roller Bearings,Spherical Roller Bearings,Needle Roller Bearings,Thrust Roller Bearings and Crossed Roller Bearings. With over 1,200 different bearing sizes and over 250K bearings in stock.

Materials

Bearing Steel

Offers high hardness, wear resistance, and load-carrying capacity, making it a common choice for thrust needle roller bearings.

Stainless Steel

Provides corrosion resistance, ideal for applications exposed to harsh environments or moisture, ensuring longevity and reliability.

Cage Materials (Steel, Brass, Thermoplastics)

Steel cages offer strength, brass cages provide enhanced lubrication characteristics, and thermoplastics are chosen for lightweight designs.

Needle Rollers (Hardened and Ground Steel)

Made of hardened and ground steel, ensuring high strength and durability, allowing the rollers to handle axial loads while maintaining a compact design.

Features

1.Axial Load Handling: Thrust needle roller bearings excel in handling axial loads, distinguishing them from bearings optimized for radial loads.

2.Compact Design: Their inherently compact design allows them to accommodate axial loads in confined spaces without sacrificing performance.

3.Needle Roller Configuration: Utilizing cylindrical needle rollers minimizes radial dimensions while optimizing their ability to handle axial loads efficiently.

4.Minimal Radial Space Requirements: Prioritizing axial load-carrying capacity, their design minimizes radial space requirements.

5.High Thrust-to-Weight Ratio: The use of needle rollers and materials contributes to a high thrust-to-weight ratio, crucial for weight-efficient applications.

6.Emphasis on Directionality: Engineered with a primary focus on managing forces along a specific axial direction.

Advantages

1.High Load Capacity: Efficiently handles substantial axial loads.

2.Low Friction and Heat Generation: Reduces energy loss and heat buildup during operation.

3.Alignment Compensation: Compensates for shaft and housing misalignment.

4.High Rigidity: Maintains structural integrity under heavy axial loads.

5.Compact Design: Smaller cross-sectional area, suitable for limited space.

6.Reduced Weight: Lightweight construction is beneficial in weight-sensitive applications.

7.Higher Speed Capability: Suitable for high-speed applications due to lower mass and friction.

Applications

- Automotive Transmissions: Efficient power transmission in gearboxes and automatic transmissions.

- Aerospace: Lightweight support in aircraft components like landing gear systems.

- Machine Tools: High rigidity for precise axial positioning in milling machines and lathes.

- Material Handling: Axial load support in conveyor systems, forklifts, and cranes.

- Industrial Gearboxes: Used in various industrial gear applications for axial load handling.

- Robotics: Compact and lightweight support in robotic joints and actuators.

- Textile Machinery: Axial load handling in spinning and winding machines in the textile industry.

Key Manufacturing Process of Needle Roller Thrust Bearings

Material Selection: Choose high-quality steel or other suitable materials for bearing components, ensuring durability and resistance to wear.

Cold Forming of Rings: Employ cold-forming processes to shape the bearing rings, reducing material waste and enhancing the mechanical properties of the components.

Heat Treatment: Subject the bearing components, especially the rings and rollers, to heat treatment processes such as hardening and tempering to achieve the desired hardness, toughness, and dimensional stability.

Precision Grinding: Utilize precision grinding techniques to achieve tight tolerances and smooth surfaces on the bearing components, ensuring proper fit and reduced friction during operation.

Assembly of Components: Assemble the individual components, including the needle rollers, cages, and rings, with precision to ensure proper alignment and functioning of the bearing.

Cage Formation: Manufacture the cages that hold the needle rollers in place using stamping or other forming processes, ensuring uniform spacing and guidance of the rollers.

FAQ - Frequently Asked Questions

A thrust needle roller bearing is a type of bearing designed to handle axial loads by using needle rollers arranged in a cage. It is compact and well-suited for applications with limited space.

They are commonly used in applications such as automotive transmissions, aerospace components, industrial gearboxes, and robotics, where efficient axial load handling is crucial.

Advantages include high load capacity, low friction, alignment compensation, high rigidity, compact design, reduced weight, and suitability for high-speed applications.

The needle rollers in thrust needle roller bearings can articulate within the bearing, allowing them to compensate for shaft and housing misalignment.

High-quality steel or other suitable materials are commonly used to ensure durability and resistance to wear.

While primarily designed for axial loads, some designs can handle limited radial loads. However, radial load capacity is not their primary strength.

They are typically lubricated with grease or oil to reduce friction and enhance performance. Lubrication helps in minimizing wear and dissipating heat.

Precision grinding ensures tight tolerances and smooth surfaces on bearing components, contributing to proper fit and reduced friction during operation.

Yes, their low mass and reduced friction make them suitable for high-speed applications in various industries.

Yes, designs include flat washers, shaft washers, and housing washers, providing versatility to suit various application requirements.

Installation and Maintenance

Installation

- Clean the Shaft and Housing: Ensure that the shaft and housing surfaces are clean and free from dirt, debris, and any residual lubricants.

- Inspect the Bearings: Before installation, inspect the thrust needle roller bearings for any damage or contamination.

- Apply Lubrication: Proper lubrication is crucial for reducing friction, preventing premature wear, and ensuring smooth operation.

- Position the Bearing Components: Carefully position the thrust needle roller bearing components, including the shaft washer, housing washer, needle rollers, and cage, in the correct order.

- Secure the Bearings: Use appropriate tools to secure the bearings in place. This may involve press-fitting the components onto the shaft or into the housing.

- Verify Axial Clearance and Preload: After installation, check and adjust the axial clearance or preload according to the bearing specifications.

Maintenance

- Regular Lubrication Inspections: Monitor and replenish lubrication regularly to reduce friction and prevent wear.

- Axial Clearance Adjustment: Periodically check and adjust axial clearance for effective axial load accommodation.

- Environmental Protection: Use seals and shields to protect bearings from contamination and moisture.

- Vibration Analysis: Implement vibration analysis for early detection of issues indicated by unusual vibrations.

- Temperature Monitoring: Regularly monitor bearing temperatures to identify potential problems and prevent overheating.

- Preventive Re-Lubrication: Schedule preventive re-lubrication to ensure a consistent and sufficient supply of lubricant.

- Condition Monitoring Systems: Utilize advanced monitoring systems for real-time assessment of bearing health and timely intervention.

Related Posts

Unveiling the Safety Secrets of Needle Roller Thrust Bearings

Table of Contents Categories Unveiling the Safety Secrets of Needle...

Read MoreRevolutionize Your Machinery: Needle Roller Thrust Bearing Insights

Table of Contents Categories Revolutionize Your Machinery: Needle Roller Thrust...

Read More