Ball Screw Bearings

Table of Contents

Definition of Ball Screw Bearings

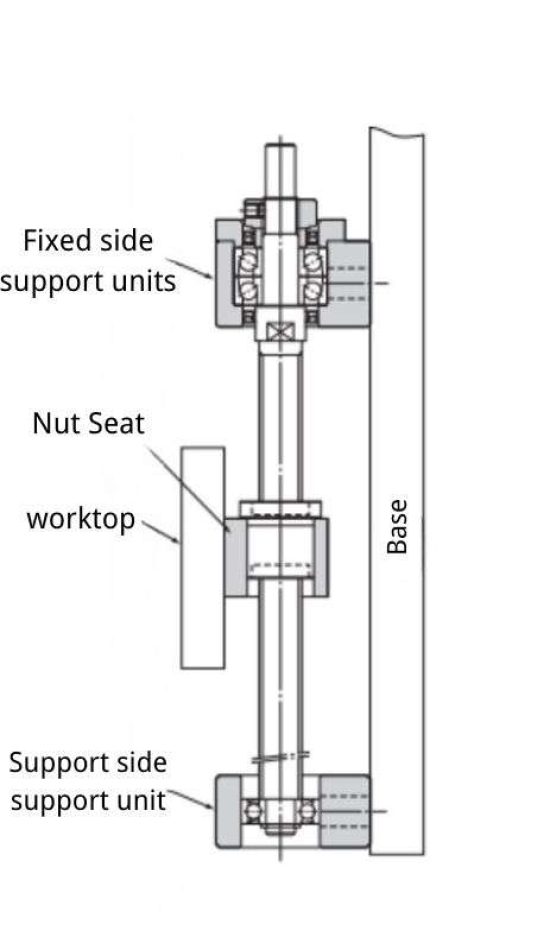

Ball screw bearings, or ball screw support bearings, are specialized bearings designed to support the high axial loads and provide precise motion control in ball screw assemblies. These bearings typically include angular contact ball bearings or deep groove ball bearings, and they play a crucial role in the efficient transfer of rotational motion to linear motion in ball screw systems, commonly used in various industrial applications such as CNC machines, robotics, and precision machinery.

FHD Bearings is an ISO 9001:2015 certified manufacturing company with a wide range of products in stock to ensure reliable quality to meet the diverse needs of our customers.

Materials of Ball Screw Bearings

– Ball screw bearings made of chrome steel are used for a wide range of general industrial applications due to their high hardness, strength, wear resistance and relatively low cost.

– Ball screw bearings using stainless steel have good corrosion resistance and are suitable for wet or corrosive environments, maintaining a high level of durability, making them particularly suitable for special applications such as medical equipment and food processing.

– FHD chose stainless steel ballscrews mainly because of their resistance to corrosion and their suitability for special industry standards to improve system reliability and extend service life.

Ceramic

– Ball screw bearings made of ceramic have the advantages of light weight, high heat resistance, and low friction, improving performance and making them suitable for high-speed and high-temperature environments.

Features of Ball Screw Bearings

- Efficient Transmission: Adoption of ball structure reduces friction resistance and improves transmission efficiency.

- High precision: Ball screw bearings have high positioning accuracy and repeatability, suitable for applications requiring high precision.

- Strong load bearing capacity: able to withstand large axial load and radial load, suitable for applications requiring high load bearing capacity.

- Automatic preload: Due to the automatic preload of the balls, the ball screw bearings are less likely to produce clearance during operation, which improves the rigidity of the system.

- High-speed movement: Due to the light weight and small inertia of the balls, ball screw bearings are suitable for high-speed movement.

- Low friction and high efficiency: The rolling of ball reduces the friction loss and improves the energy utilization efficiency.

- High Reliability: Simple structure, fewer parts, therefore higher reliability and lower maintenance costs.

Advantages of Ball Screw Bearings

- The material is pure steel for extended service life.

- Incorporates tighter preload tolerances for chatter-free cutting and tighter width tolerances for easy assembly without regrinding the end caps.

- Revolutionary cage design accommodates more balls for higher load capacity.

- ABEC 9/ISO P2 axial running tolerances provide the highest accuracy for repeatable positioning on machine tools.

- The double row bearing series is equipped with one-piece, low-torque contact seals that prevent contaminant ingress, ensuring reliable bearing operation and extended bearing life.

- Flanged (MMF) and non-flanged (MMN) series bearings are available to simplify mounting of standard and swivel nut types.

Taxonomy of Ball Screw Bearings

Ball Screw Bearings

Ball Screw Bearings

Ball screw bearings are highly efficient, high-precision, load-carrying mechanical transmission elements for a variety of industrial applications, providing reliable motion control and positioning.

Ball Screw Bearings

The ball bearings are housed in the nut, which is then mounted on the threaded shaft. As the threaded shaft rotates, the ball bearings move along the thread, causing the nut to move linearly along the shaft. The ball screw is known for its high accuracy, high efficiency, and low friction.

Applications of Ball Screw Bearings

- CNC machine tools: Used to provide high-precision, high-rigidity motion control to ensure the accuracy and stability of machine tool operation.

- Industrial robots: In industrial automation, ball screw bearings are used in robot joints and actuators to provide precise motion control.

- Printing Equipment: Used for paper transport and positioning to ensure high precision and speed in the printing process.

- Medical equipment: In medical imaging equipment, surgical robots and other fields, to provide accurate position adjustment and movement.

- Aerospace: Used in a variety of mechanical systems for aircraft and spacecraft to ensure precise control of the vehicle.

- Automotive Manufacturing: Automation equipment used in automotive production lines to provide highly accurate part positioning and motion.

- Electronics Manufacturing: Used in semiconductor production equipment, electronic assembly lines, etc. to provide precise motion and positioning.

- Energy equipment: Used in wind turbines, solar tracking systems, etc. to ensure the efficient operation of energy equipment.

Key Manufacturing Process of Ball Screw Bearings

Raw Material Preparation

Selection of high quality bearing steel or other suitable materials to ensure uniformity of material and accuracy of alloy composition.

Cold Drawing or Hot Extrusion

The raw material is cold-drawn or hot-extruded to the desired shape, such as a round or square cross-section.

Rough Turning

The extruded or cold-drawn material is rough turned to form the initial bar shape.

Hardening

The roughly turned bar is hardened to increase its hardness and strength and to increase resistance to wear.

Grinding

The hardened screws are precision ground by a grinder to ensure the smoothness of the surface and the accuracy of the dimensions.

Thread Rolling

Threads are rolled on the screw to ensure the accuracy and quality of the threads.

Ball Guiding Groove

Manufacture the guiding groove on the surface of the screw for accommodating the ball to ensure the smooth guiding of the ball in the process of movement.

Assembling

Assembling the manufactured screws with bearing jackets, end supports and other components to form the final ball screw bearings.

Inspection

Quality inspection of the finished products, including dimensional measurement, thread quality, surface finish, etc., to ensure that the products meet the design requirements.

Lubrication

Add appropriate lubricant inside the ball screw bearing to improve the friction performance and life.

FAQ - Frequently Asked Questions

A ball screw bearing is a mechanical transmission component that converts rotational motion into linear motion using ball bearings rolling along a threaded rail.

They offer high transmission efficiency, precision, strong load-bearing capacity, automatic preloading, suitability for high-speed motion, among other advantages.

They are extensively used in industries such as CNC machining, industrial robotics, medical equipment, printing machinery, aerospace, and automotive manufacturing.

Factors like load requirements, precision needs, speed, and environmental conditions play a role in selecting the appropriate ball screw bearing.

Materials include chrome steel for general use, stainless steel for corrosion resistance, and ceramics for high-temperature and low-friction applications.

Regular cleaning, lubrication, and checking for wear are common maintenance tasks to ensure optimal performance and longevity.

Yes, ball screw bearings are designed to handle both axial and radial loads, making them versatile for various applications.

Precision ball screw bearings offer higher accuracy and are designed for applications requiring tight tolerances, while standard bearings provide a balance of performance for general use.

The low friction and rolling motion of ball screw bearings reduce energy loss, contributing to increased efficiency in high-speed operations.

Proper lubrication is crucial to reduce friction, prevent wear, and ensure smooth operation, enhancing the overall performance and lifespan of ball screw bearings.

Installation and Maintenance of Ball Screw Bearings

Installation

- Preparation: Ensure that the working environment is clean and check the integrity of the bearings, screws and associated components.

- Measurement and Alignment: Use accurate measuring tools to check the dimensions of the bearings and screws to ensure that they meet the design requirements and are correctly aligned.

- Cleaning: Clean the surfaces of the bearings and screws to ensure that no foreign matter or dirt interferes with the installation.

- Lubrication: Bearings should be properly lubricated prior to installation to ensure adequate lubrication during initial operation.

- Assembly: Assemble the bearings, screws and other components properly according to the instructions provided by the manufacturer.

- Adjust Preload: Adjust bearing preload according to manufacturer’s recommendations to ensure proper friction and smooth motion.

- Connect Power Source: Connect ball screw bearings to the appropriate power source to ensure proper operation of the drive train.

Maintenance:

- Regular Lubrication: According to the manufacturer’s recommendations, add the right amount of lubricant to the ball screw bearings regularly to ensure their smoothness during operation.

- Regular Inspection: Regularly inspect the condition of the bearings and screws, pay attention to whether there is any abnormal noise, vibration or temperature increase.

- Cleaning and maintenance: Regularly clean the dirt on the surface of the bearings and screws to ensure a clean working environment and avoid damage to the bearings caused by foreign objects.

- Replacement of worn parts: Once obvious wear is found on the bearings or screws, replace the damaged parts in time to prevent further damage to the whole system.

- Avoid overloading: Avoid use beyond the designed load range to prevent excessive wear of the bearings.

- Regular Calibration: For applications requiring high accuracy, perform regular calibration to ensure the system remains accurate.

- Pay attention to the working environment: Avoid use in harsh working environments, such as excessively humid or hot environments, to extend bearing life.

Related Posts

Ball Screws and Lead Screws: A Mechanical Controversy

Categories Ball Screws And Lead Screws: A Mechanical Controversy Table...

Read More