Deep Groove Ball Bearings

Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (27)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Definition of Deep Groove Ball Bearings

Deep groove ball bearings are the most widely used bearing type known for their versatility. Engineered for low friction, minimal noise, and vibration, these bearings facilitate high rotational speeds. They effortlessly handle radial and axial loads in both directions, boast easy mounting, and demand less maintenance compared to alternative bearing types.

FHD Bearings is an ISO 9001:2015 certified manufacturing enterprise that stocks a full range of deep groove ball bearings, angular contact ball bearings, thrust ball bearings, Self-aligning ball bearings and ceramic ball bearings. With over 1,200 different bearing sizes and over 250K bearings in stock.

Materials of Deep Groove Ball Bearings

Chrome Steel

– The most common material for ball bearings due to its high durability and affordability.

Stainless Steel

– Offers corrosion resistance and is suitable for applications where hygiene is important.

Silicon Nitride (Si3N4)

– Known for its exceptional hardness, low weight, and resistance to high temperatures and corrosion.

Zirconia Dioxide (ZrO2)

– Combines high hardness and corrosion resistance, often used in high-performance applications.

Polyethylene

– Used in applications where non-metallic, lightweight, and corrosion-resistant bearings are required.

Polypropylene

– Suitable for applications with low loads and chemical resistance needs.

Features of Deep Groove Ball Bearings

Versatility: Our deep groove ball bearings are designed to accommodate various radial loads and axial loads in both directions.

High Precision: Engineered with precision to ensure smooth and efficient operation in diverse applications.

Durable Construction: Manufactured with high-quality materials to enhance longevity and reliability, even in challenging operating conditions.

Low Friction: Reduced friction ensures energy efficiency and contributes to the overall performance of machinery.

Sealing Options: Available with various sealing options to protect against contamination and extend the bearing’s service life.

Quiet Operation: Engineered for low noise levels, making them suitable for applications where noise is a critical factor.

Wide Temperature Range: Suitable for a broad range of temperatures, ensuring consistent performance in different environments.

Customization: Our bearings support OEM/ODM customization to meet specific requirements of different applications.

Advantages of Deep Groove Ball Bearings

- High load carrying capacity: Deep groove ball bearings are uniquely designed to withstand large radial and axial loads, giving them excellent load carrying capacity in a wide range of applications.

- Suitable for high speed operations : Due to their design, which reduces friction between the rolling elements and rings, deep groove ball bearings are suitable for high speed operations, providing stable and efficient performance.

- Ease of mounting and maintenance: Simple construction and ease of mounting and maintenance make them the preferred bearing type for many industrial applications.

- Versatility: Deep groove ball bearings are suitable for a wide range of industrial and mechanical applications, including electric motors, automobiles, household appliances and other fields, showing their wide versatility.

- Good sealing and dustproof performance: Different types of seals are provided to prevent dust, moisture and other contaminants from entering the bearing interior and improve its service life.

Applications of Deep Groove Ball Bearings

- Motors and generators: Used to support the rotors of motors and generators, providing stable rotational motion.

- Automotive industry: for wheels, drive trains, engines and chassis components of automobiles.

- Wind turbines: used to support the rotation of wind turbine blades, with the ability to withstand dynamic loads and high speeds.

- Agricultural machinery: for agricultural machinery and equipment, such as tractors, harvesters, etc..

- Household appliances: for electric fans, washing machines, refrigerators and other home appliances.

- General machinery: in a variety of general-purpose machinery and equipment, such as pumps, fans, conveyor belts and so on.

- Industrial transmission system: used to support a variety of industrial transmission system of the rotating parts.

- Machine tools: used to support the spindle and other rotating parts of machine tools.

- Bearing support: in a variety of bearing support and support structure applications.

- Rollers and raceways: Used as rolling elements in conveyor belts, raceways and other equipment.

- Bicycles and motorcycles: Used to support the rotation of wheels.

- Aviation and aerospace industry: used in various systems of aircraft and spacecraft.

Key Manufacturing Process of Deep Groove Ball Bearings

Raw material selection: Selection of high quality bearing steel or other alloy materials suitable for the manufacture of deep groove ball bearings. The quality and properties of the material are critical to the life and performance of the bearing.

Cold work and heat treatment: Raw materials are cold worked and heat treated to improve their hardness and wear resistance. This step helps to ensure that the bearings are able to withstand high loads and long periods of use without failure in actual operation.

Bearing outer and inner ring machining: The outer and inner rings of the bearings are precision machined using advanced CNC machines to ensure dimensional accuracy and surface finish.

Ball Manufacturing: The production of rolling balls for bearings is usually accomplished through processes such as shearing and shaping of bearing steel.

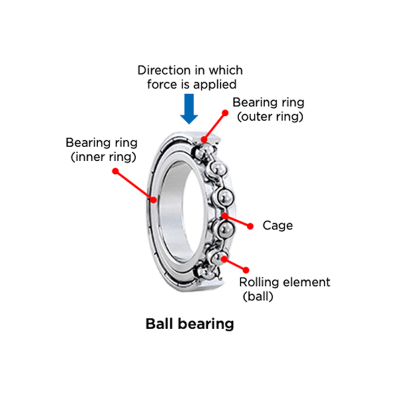

Assembly: The assembly of the various components of a bearing (outer ring, inner ring, rolling balls, etc.). This process usually involves the use of specialized equipment and tools to ensure that the components are correctly positioned and fit together.

Quality Inspection: Strict quality inspection is carried out on the finished deep groove ball bearings, including dimensional measurement, appearance inspection, bearing running test, etc., to ensure that the bearings meet the design requirements and quality standards.

Packing and shipping: Pack the bearings passing the quality inspection, ready to be shipped to customers or integrated into the final products.

FAQ - Frequently Asked Questions

Deep groove ball bearings are a common type of rolling bearing with a deep groove structure, suitable for carrying radial and axial loads.

Deep groove ball bearings have the advantages of high load carrying capacity, high speed operation, simple structure, easy installation, etc. They are widely used in various industrial and mechanical fields.

Deep groove ball bearings support rotary motion by rolling the balls between the inner and outer rings, thereby reducing friction.

Factors such as load, speed, size, sealing performance and environment need to be considered when selecting deep groove ball bearings to ensure suitability for a particular application.

Yes, deep groove ball bearings require proper lubrication to minimize friction, reduce wear, and ensure reliable operation over long periods of time.

Life depends on the conditions of use and loads, but properly maintained and lubricated deep groove ball bearings usually have a long life.

Deep groove ball bearings are mainly used to carry radial loads, whereas angular contact ball bearings are suitable for carrying larger radial and axial loads.

Yes, there are some deep groove ball bearings designed for high temperature environments with special materials and lubrication.

Situations where deep groove ball bearings need to be replaced include excessive wear, damage, abnormal noise, and other conditions that affect their normal operation.

Attention should be paid to the direction and cleanliness of the bearings when mounting, and the lubrication and sealing performance need to be checked regularly during maintenance, and overload operation should be avoided.

Installation and Maintenance

Installation

- Preparation:

Ensure that the work area is clean and prepared with the required tools and equipment.

Check the deep groove ball bearings and their mounting environment to make sure they are clean and free of impurities. - Inspect the bearings:

Check the appearance of the bearings to ensure that there is no damage or foreign matter.

Verify the marking of the bearings to ensure proper installation. - Measure shaft and hole dimensions:

Measure the diameter of the shaft and the diameter of the hole to ensure they meet the design requirements. - Add lubrication:

Add an appropriate amount of grease or oil inside the bearing to ensure adequate lubrication. - Slight preload:

Slightly preload the bearings before mounting to ensure that they can adapt to the loads during operation. - Bearing mounting:

Lightly mount the bearing onto the shaft, ensuring proper orientation.

This can be done by using a light hammering of the shaft and bearing or a special mounting tool. - Mounting the outer ring:

When mounting the outer ring, ensure that an even force is applied to avoid deformation or damage. - Positioning:

Ensure that the bearing is correctly positioned on the shaft and in the seat bore by measuring and adjusting. - Lock nut or sleeve:

If applicable, install and properly lock the nut or sleeve to ensure the bearing is securely fastened. - Verify bearing rotation:

After installation is complete, manually rotate the bearing to ensure smooth operation and no unusual noise.

Maintenance

- Regular lubrication:

According to the conditions of use, check the lubrication of bearings regularly to ensure sufficient grease or lubricant. - Seal check:

Regularly check the seals of the bearings to ensure that they are effective in preventing the entry of dust and contaminants. - Vibration and noise monitoring:

Regularly monitor the vibration and noise levels of the bearings, abnormalities may be a sign of bearing problems. - Temperature monitoring:

Regularly check the temperature of the bearings, an abnormal rise in temperature may be an indication of bearing failure. - Cleaning:

Regularly clean the bearings and their surroundings to ensure that there is no accumulation of dust or deposits on the bearing surfaces. - Regular checking of bearing clearance:

Depending on the type of bearing and requirements, check the bearing clearance periodically to make sure it is within the normal range. - Periodic replacement:

According to the service life and working conditions, replace the bearings regularly to avoid equipment failure due to excessive wear. - Keep records:

Record the maintenance history of the bearings, including lubrication intervals, replacement dates and other information to help predict the life of the bearings.

Related Posts

Optimizing Deep Groove Ball Bearing Lifespan through Effective Sealing And Lubrication

Table of Contents Categories Optimizing Deep Groove Ball Bearing Lifespan...

Read MoreThe Heart of Machinery: Deep Groove Ball Bearings

Explore the pivotal role of Deep Groove Ball Bearings in...

Read More