Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Silent Powerhouses: Exploring the Magic of EMQ Bearings

Introduction

EMQ Bearings, an acronym denoting Electric Motor Quality, represent a specialized class of bearings explicitly tailored for deployment in electric motors and tools. Celebrated for their exceptional attributes such as high-speed capabilities, minimal noise and vibration, and extraordinary durability, these bearings have emerged as indispensable elements in the realm of modern machinery.

In the vast landscape of machinery and industrial applications, the pivotal role played by bearings cannot be overstated. Among these, EMQ Bearings stand out as silent powerhouses, meticulously engineered components that propel efficiency and performance across various sectors. This blog post embarks on a comprehensive exploration of the enchanting world of EMQ Bearings, unraveling the intricate technology, unveiling diverse applications, and elucidating the profound impact these precision-engineered components have on modern machinery.

Understanding EMQ Bearings

Definition and Origin of EMQ Bearings

EMQ (Electric Motor Quality) bearings, standing for Electric Motor Quality bearings, are a specialized type of rolling-element bearing designed to meet stringent requirements for use in electric motors. These bearings are characterized by their superfinished rolling contact surfaces, which are polished to a mirror-like finish to ensure very smooth rotation. The term “electric motor quality” implies that these bearings have been manufactured to precise tolerances and noise levels, often conforming to ABEC 3, ABEC 5, Z2V2, Z3V3, and Z4V4 specifications. The origin of EMQ bearings is rooted in the need for high-performance bearings in electric motor applications, where reduced friction, lower noise, and increased reliability are critical. The designation “EMQ” assures users that the bearings are suitable for the high demands of electric motors, and it is a term commonly used in the industry to denote a higher standard of bearing performance.

Key Characteristics Setting EMQ Bearings Apart

EMQ bearings distinguish themselves through several key characteristics that set them apart in the realm of bearings. Firstly, EMQ bearings are meticulously engineered and manufactured to meet stringent standards, ensuring optimal performance in electric motor applications. These bearings are designed for reduced noise, vibration, and friction, contributing to smoother and more efficient operation of electric motors. Additionally, EMQ bearings often incorporate high-quality materials and advanced technologies, enhancing their durability and reliability. The precision in their construction and the use of specialized lubricants make EMQ bearings well-suited for demanding industrial environments. Overall, the combination of precision engineering, reduced friction, and enhanced durability positions EMQ bearings as a preferred choice for applications requiring optimal electric motor performance.

The Technology Behind EMQ Bearings

Design Principles

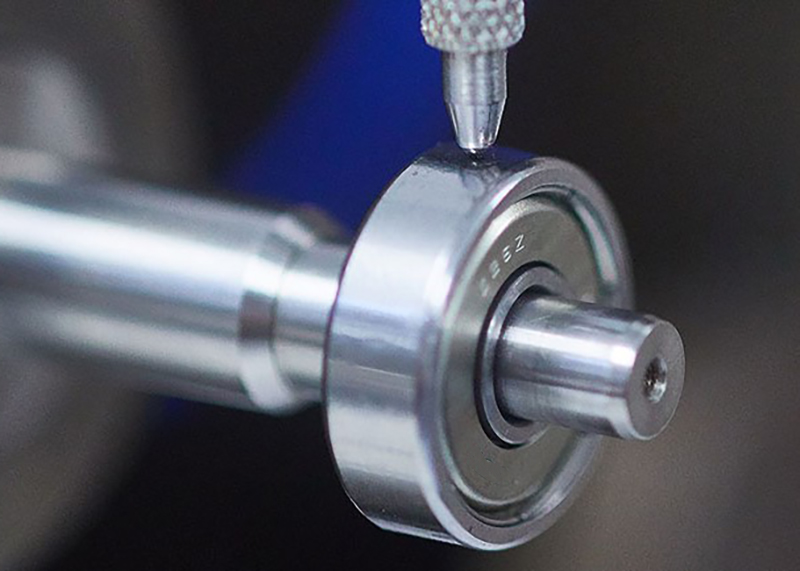

The design principles of EMQ bearings embody a meticulous approach to ball bearings, raceway finish, and cage design, collectively defining their optimal functionality. Beginning with ball quality, EMQ bearings prioritize precision and consistency in manufacturing, ensuring uniformity for enhanced performance. The raceway finish is equally critical, as it directly influences the smoothness of rotation and minimizes friction. EMQ bearings also feature innovative cage designs, meticulously crafted to provide stability, reduce noise, and maintain proper ball spacing. These design elements collectively contribute to the overall efficiency, reliability, and longevity of EMQ bearings, making them a cornerstone in applications requiring top-tier electric motor performance.

Materials Used in EMQ Bearings

EMQ bearings are typically crafted from a selection of quality materials, chosen for their contribution to robustness and longevity in diverse applications. The key materials used in the production of EMQ bearings include:

High-Grade Steel Alloys: Specialized steels, such as chrome steel (SAE 52100), form a fundamental component. These alloys provide exceptional strength, hardness, and corrosion resistance.

Advanced Polymers: Certain components of EMQ bearings may incorporate advanced polymers. These polymers enhance the bearings’ performance by contributing properties like wear resistance and durability.

Ceramic Materials: In some instances, ceramic materials like silicon nitride are employed, offering benefits such as high-temperature resistance and reduced friction.

The meticulous combination of these materials establishes EMQ bearings as reliable components capable of withstanding the challenging conditions encountered in various applications.

Manufacturing Process Ensuring Precision

The manufacturing process of EMQ bearings is intricately designed to ensure unparalleled accuracy in every aspect. Beginning with the selection of high-grade materials, such as precision steel alloys, advanced polymers, and ceramic components, the process follows stringent quality control measures. Precision machining techniques are employed to craft intricate bearing components with exacting tolerances. Advanced technologies, including computer numerical control (CNC) machining and automated assembly, contribute to the consistency and precision of each bearing produced. Stringent inspection and testing protocols at various stages of manufacturing further guarantee the accuracy of dimensions, surface finishes, and overall performance. This meticulous approach in the manufacturing process establishes EMQ bearings as reliable components with precise geometry, ensuring optimal functionality in electric motor applications.

Advantages of EMQ Bearings

EMQ bearings offer several unique advantages that make them stand out in various applications:

- Precision Engineering: EMQ bearings are crafted with meticulous precision, ensuring exacting tolerances and consistent performance.

- Reduced Friction: The design and materials used in EMQ bearings contribute to minimized friction, promoting smoother operation and increased efficiency.

- Lower Noise and Vibration: EMQ bearings are engineered for reduced noise and vibration levels, making them ideal for applications where quiet and smooth operation is crucial.

- Optimized for Electric Motors: These bearings are specifically designed to meet the unique requirements of electric motor applications, ensuring reliable performance.

- Enhanced Durability: High-quality materials, specialized steels, and advanced polymers contribute to the durability and longevity of EMQ bearings, even in demanding conditions.

These unique advantages collectively position EMQ bearings as a preferred choice in applications where precision, durability, and efficiency are paramount.

Applications of EMQ Bearings

EMQ bearings find applications across various industries due to their precision engineering and optimized performance. Here are five common applications:

Electric Motors: As the name suggests, EMQ bearings are specifically designed for electric motor applications, providing smooth and efficient operation in motors used in appliances, power tools, industrial machinery, and more.

Automotive Systems: EMQ bearings are used in automotive systems, including electric power steering, alternators, starters, and various components in hybrid and electric vehicles. Their low friction and durability contribute to improved automotive performance.

Industrial Machinery: EMQ bearings are employed in a wide range of industrial machinery, such as pumps, compressors, conveyors, and gearboxes. Their precision and reliability make them suitable for demanding industrial applications.

HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems utilize EMQ bearings in components like fans and blowers. The reduced noise and vibration levels are particularly advantageous in HVAC applications.

Household Appliances: EMQ bearings are commonly used in household appliances like washing machines, refrigerators, and dishwashers. Their efficient and reliable performance ensures the smooth operation of these appliances.

These applications highlight the versatility of EMQ bearings, making them essential components in various devices and machinery across different industries.

How EMQ Bearings Enhance Efficiency

EMQ bearings play a pivotal role in enhancing efficiency across diverse applications. Their precision engineering, utilizing high-grade materials and advanced manufacturing processes, results in reduced friction during operation. By minimizing friction, EMQ bearings significantly contribute to improved energy efficiency within electric motors and machinery. The carefully chosen materials, including specialized steels and advanced polymers, ensure durability and resistance to wear, further extending the operational life of the bearings. The lowered friction not only conserves energy but also leads to less heat generation, preventing unnecessary energy loss. The bearings’ optimized design, coupled with meticulous manufacturing standards, results in smoother rotations, reduced noise, and diminished vibration levels, all of which contribute to increased overall system efficiency. Whether in electric motors, automotive systems, industrial machinery, or household appliances, EMQ bearings stand as key components driving efficiency improvements in diverse operational environments.

EMQ-Rated Bearings: What Sets Them Apart

The distinction between EMQ (Electric Motor Quality) bearings and those specifically rated as EMQ lies in the precision and quality standards. While all EMQ bearings are designed for electric motor applications, those explicitly labeled as EMQ rated undergo additional scrutiny and adherence to stringent criteria. EMQ rated bearings often adhere to more precise tolerances, superior manufacturing processes, and stricter quality control measures, ensuring an even higher level of performance and reliability. The “EMQ rated” designation typically signifies a premium tier within the already high-quality category of EMQ bearings, emphasizing enhanced precision and meticulous engineering to meet the most demanding requirements of electric motor applications.

Tips for Choosing and Maintaining EMQ Bearings

Choosing the correct EMQ bearing

Choosing the correct EMQ bearing involves considering various factors to match the specific requirements of the application. Start by understanding the operational conditions, including speed, load, and environmental factors. Select a bearing with the appropriate size and load-carrying capacity, ensuring it can withstand the demands of the equipment. Consider the level of precision required for the application, as some applications may benefit from the additional precision provided by EMQ rated bearings. Additionally, evaluate the temperature and lubrication conditions to choose a bearing with suitable materials and lubrication options. Consulting with bearing manufacturers or experts can provide valuable insights into selecting the right EMQ bearing for optimal performance and longevity in a given application.

Best Practices for Maintenance

Maintaining EMQ bearings involves crucial skills to ensure prolonged reliability and optimal performance. Regular lubrication is paramount, with the choice of appropriate lubricants and monitoring intervals based on operating conditions. Proper installation techniques, including accurate alignment and mounting, prevent premature wear and extend bearing life. Regular inspections to detect signs of wear, such as unusual noise or vibration, allow for timely replacements or repairs. Ensuring that environmental factors, such as temperature and contamination, are within specified limits further safeguards bearing integrity. Developing proficiency in these maintenance skills not only enhances the longevity of EMQ bearings but also contributes to the overall efficiency and functionality of the equipment in which they are employed.

Conclusion

In conclusion, the magic of EMQ Bearings lies in their silent yet powerful ability to drive efficiency and performance across a myriad of applications. As we journeyed through the intricacies of these silent powerhouses, it became evident that they transcend mere mechanical components, emerging as enablers of efficiency, reliability, and progress in the vast landscape of modern machinery. The exploration into the realm of EMQ Bearings is not just a technical journey but a narrative of how these precision-engineered components play a transformative role in shaping the future of technology. Their silent influence is the echo of progress, and as we anticipate the future, the role of EMQ Bearings is bound to become even more pivotal in the continued evolution of machinery and industrial applications.

References

1.”EMQ Bearings” from AXIS Bearings;

2. “What Are EMQ-Rated Bearings?” from BEARING TiPS;

3. “What Are EMQ Ball Bearings?” from BEARINGS DIRECT.