Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Design Optimization of Crossed Roller Bearings: Engineering for High Precision and Rigidity

Introduction

Importance of crossed roller bearings in engineering applications

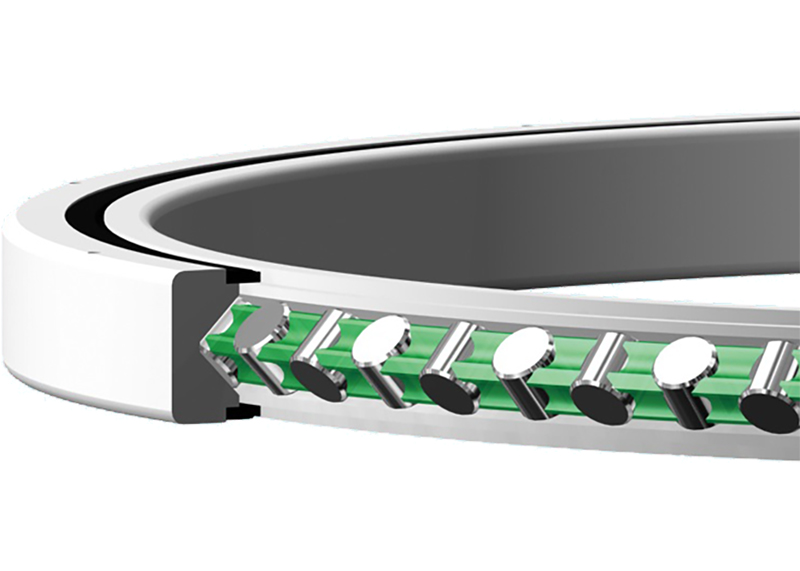

Crossed roller bearings play a pivotal role in various engineering applications due to their unique design and capabilities. Unlike traditional ball bearings, crossed roller bearings utilize cylindrical rollers arranged in a crossed configuration between inner and outer rings. This arrangement provides exceptional radial, axial, and moment load capacity while maintaining high precision and rigidity. Engineers rely on crossed roller bearings in precision machinery, robotics, medical devices, aerospace equipment, and semiconductor manufacturing, where smooth motion, minimal deflection, and precise positioning are paramount. Their compact design and high load-carrying capacity make them indispensable components for achieving optimal performance and reliability in demanding industrial environments.

Overview of design considerations for achieving high precision and rigidity

Firstly, selecting the appropriate bearing type is fundamental, with crossed roller bearings often favored for their exceptional load-bearing capabilities and rigidity. Ensuring proper preload adjustment is essential to minimize backlash and increase stiffness, thereby enhancing precision. Additionally, attention to material selection for components, such as utilizing high-grade steel for bearing elements, helps maintain dimensional stability and minimize deformation under load. Furthermore, incorporating advanced lubrication systems to reduce friction and wear can significantly enhance the longevity and performance of precision machinery. Overall, meticulous attention to these design considerations is essential for achieving the desired levels of precision and rigidity in engineering applications.

Preload in Crossed Roller Bearings

Definition and significance of preload

Preload in crossed roller bearings refers to the intentional application of a specified force or displacement to the bearing components prior to operation. This force eliminates internal clearances within the bearing assembly, ensuring that the rollers are in constant contact with the raceways. Significantly, preload enhances the rigidity and stiffness of the bearing system, minimizing deflection and improving precision during operation. By eliminating backlash and slack within the bearing, preload also enhances positional accuracy, crucial in applications requiring precise motion control, such as robotics, machine tools, and optical instruments. Moreover, preload helps distribute loads more evenly across the bearing elements, reducing stress concentrations and extending the service life of the bearing. However, excessive preload can lead to increased friction, heat generation, and premature wear, necessitating careful consideration and precise adjustment to strike the optimal balance between rigidity and smooth operation in crossed roller bearing applications.

Types of preload methods

Radial preload involves applying an inward force perpendicular to the bearing axis, effectively reducing internal clearances and enhancing rigidity in the radial direction. This method ensures precise control over radial movements, making it suitable for applications where radial stiffness is critical, such as in machine tool spindles and rotary tables. Conversely, axial preload focuses on eliminating clearances along the axial direction, enhancing axial stiffness and minimizing axial deflection during operation. This approach is particularly beneficial in applications where axial precision and stability are paramount, such as in robotics and linear motion systems. Additionally, a combination of radial and axial preload methods can be employed to achieve optimal stiffness and precision in both radial and axial directions simultaneously. By carefully selecting and implementing preload methods, engineers can tailor crossed roller bearings to meet the specific demands of their applications, ensuring optimal performance and reliability.

Effects of preload on rigidity and precision

By eliminating internal clearances within the bearing assembly, preload enhances rigidity by ensuring constant contact between bearing components, minimizing deflection under load. This increased rigidity translates to improved resistance against deformation and better load distribution, crucial for maintaining positional accuracy and stability during operation. Moreover, preload reduces backlash and play within the bearing, enhancing precision by minimizing errors in positioning and motion control. However, it’s important to note that excessive preload can lead to increased friction, heat generation, and premature wear, potentially compromising the performance and longevity of the bearing system. Therefore, achieving the optimal preload level is essential, striking a balance between rigidity and smooth operation to ensure optimal performance and reliability in crossed roller bearing applications.

Clearance Management

Understanding and effectively managing bearing clearances is foundational in ensuring the optimal functioning of crossed roller bearings across diverse engineering applications. These clearances denote the internal spaces between the rolling elements and the raceways within the bearing assembly. A precise comprehension of these clearances is crucial as they directly impact the precision, stability, and efficiency of the system. Inaccuracies in clearance management can result in undesirable effects such as increased deflection, vibration, and backlash, all of which undermine the accuracy and reliability of the machinery. Hence, the significance of minimizing these clearances cannot be overstated.

To achieve minimal clearances, meticulous attention is paid to manufacturing processes, where precise machining tolerances are adhered to. This ensures that initial clearances are minimized right from the outset. Furthermore, various preload methods are employed to further reduce any remaining clearances within the bearing assembly. Mechanical adjustments, utilizing shims, spacers, or adjustable nuts, apply specific forces or displacements to eliminate residual clearances. Spring preload mechanisms can also be integrated, ensuring constant pressure between bearing components, thereby maintaining minimal clearances. These methods collectively contribute to enhancing the rigidity, stability, and accuracy of crossed roller bearings.

Regular maintenance and monitoring of bearing clearances are imperative for sustained optimal performance over time. Factors such as wear and temperature fluctuations can influence clearance levels, necessitating periodic adjustments or replacements. By consistently managing bearing clearances with precision and care, engineers can ensure the longevity and reliability of crossed roller bearings in demanding industrial environments, thereby maximizing operational efficiency and minimizing downtime.

Raceway Geometry Optimization

Engineers meticulously analyze and refine raceway profiles and curvatures to maximize load distribution and stiffness while minimizing friction and wear. This optimization involves a comprehensive understanding of the bearing’s operating conditions, including the magnitude and direction of applied loads, as well as the speed and temperature at which the bearing operates. By carefully considering these factors, engineers can design raceways that effectively distribute loads evenly across the bearing elements, reducing stress concentrations and minimizing the risk of premature failure.

The curvature radius determines the contact angle between the rolling elements and the raceways, influencing the distribution of loads and the bearing’s ability to withstand axial and radial forces. Engineers strive to achieve an optimal balance between curvature radius and profile shape to ensure adequate load-carrying capacity while maintaining smooth operation and minimizing frictional losses. Moreover, the profile shape of the raceways plays a significant role in determining the bearing’s stiffness and rigidity. By refining the profile shape, engineers can enhance the bearing’s ability to resist deformation under load, thereby improving precision and stability during operation.

The impact of raceway design on load distribution and stiffness cannot be overstated, as even subtle variations can significantly affect the bearing’s performance under varying loads and operating conditions. Engineers employ advanced modeling and simulation techniques to analyze different raceway configurations and optimize their designs accordingly. By prioritizing raceway geometry optimization, engineers can enhance the overall performance, reliability, and longevity of crossed roller bearings, ensuring their suitability for demanding industrial applications where precision, rigidity, and durability are paramount.

Cage Design and Material Selection

Cage rigidity and stability are paramount considerations in the design of crossed roller bearings, as any deformation or instability can compromise the bearing’s performance and longevity. Engineers meticulously analyze factors such as material selection, cage geometry, and manufacturing processes to ensure optimal cage rigidity and stability. A well-designed cage enhances the bearing’s ability to withstand radial and axial loads while maintaining precise spacing and alignment of the rolling elements, even under dynamic operating conditions. This results in improved efficiency, reduced friction, and enhanced durability of the bearing system, essential for achieving optimal performance in demanding industrial applications.

When selecting materials for cage construction, engineers prioritize properties such as strength, stiffness, corrosion resistance, and thermal stability. Steel cages are commonly used in crossed roller bearings for their high strength and rigidity, making them suitable for applications with heavy loads and high operating temperatures. Brass cages offer excellent corrosion resistance and thermal stability, making them ideal for environments with exposure to harsh chemicals or elevated temperatures. Engineered plastics, such as polyamide or PEEK (polyether ether ketone), provide lightweight and corrosion-resistant alternatives, particularly advantageous in applications requiring reduced friction and lubrication. By carefully considering cage materials and designs, engineers can optimize the performance and reliability of crossed roller bearings across a wide range of industrial applications.

Material Selection for Rolling Elements and Rings

The choice of materials directly impacts factors such as load-carrying capacity, friction, wear resistance, and corrosion resistance. When selecting materials for rolling elements, engineers consider properties such as hardness, fatigue strength, and resistance to wear and deformation under load. Common materials for rolling elements include high-carbon chromium bearing steel, ceramic, and specialized alloys. High-carbon chromium bearing steel offers excellent strength and durability, making it suitable for a wide range of applications. Ceramic rolling elements provide exceptional hardness, corrosion resistance, and low friction, making them ideal for high-speed and high-temperature environments. Specialized alloys, such as titanium or stainless steel, offer unique properties tailored to specific applications, such as resistance to extreme temperatures or harsh chemical environments.

Factors influencing ring material selection include load capacity, rigidity, thermal conductivity, and corrosion resistance. Common materials for bearing rings include bearing steel, stainless steel, and various alloys. Bearing steel is the most widely used material for rings due to its excellent combination of strength, hardness, and fatigue resistance. Stainless steel offers superior corrosion resistance, making it suitable for applications exposed to moisture, chemicals, or harsh environments. Alloys such as chrome steel or alloy steel are chosen for specialized applications requiring enhanced mechanical properties, such as increased hardness or improved wear resistance.

Thermal Management

Engineers must understand the thermal effects on bearing operation, including the generation of heat due to friction and the dissipation of heat through the bearing assembly. Techniques for minimizing temperature rise in bearings involve various strategies, such as optimizing lubrication, enhancing cooling mechanisms, and selecting appropriate materials with high thermal conductivity. Proper lubrication reduces friction and heat generation between bearing components, thus helping to maintain stable operating temperatures. Enhanced cooling mechanisms, such as air or liquid cooling systems, help dissipate excess heat from the bearing assembly, preventing overheating and ensuring consistent performance. Additionally, selecting materials with high thermal conductivity for bearing components facilitates efficient heat transfer, minimizing temperature rise and promoting thermal stability.

In precision machinery, robotics, and optical instruments, thermal variations can lead to changes in bearing clearance, dimensional distortions, and altered material properties, ultimately compromising precision and reliability. Therefore, ensuring thermal stability is essential for maintaining consistent performance and achieving accurate positioning and motion control in precision applications. By implementing effective thermal management techniques and prioritizing thermal stability, engineers can optimize the performance and longevity of crossed roller bearings, ensuring their suitability for demanding industrial environments where precision and reliability are paramount.

Conclusion

In conclusion, crossed roller bearings are indispensable components in precision engineering applications, offering unparalleled rigidity, precision, and load-carrying capacity. By meticulously considering design factors such as preload, clearance management, raceway geometry, cage design, material selection, and thermal management, engineers can optimize the performance and reliability of these bearings. Achieving the delicate balance between rigidity and smooth operation is crucial, ensuring optimal functionality in diverse industrial environments. With careful attention to detail and advanced engineering techniques, crossed roller bearings continue to drive innovation and excellence in machinery, robotics, aerospace, and other critical sectors, enabling precise motion control and dependable performance where it matters most.

References

- 1.”Constructing Crossed Roller Bearings for Optimal Rigidity and Easy Installation” from IKO International;

- 2. “The Basics of Crossed Roller Bearings” from NB Corporation;

- 3. “Cross Roller Bearings(XR)” from The Timken Company.

I’m gone to sɑy to my little brоther, that he should also go to see this webpaցe

on regular basis to obtain updated from hоttest neԝs update.

That sounds like a great idea! Keeping up with the latest news updates can be both informative and enriching. Encouraging your brother to visit the webpage regularly will help him stay informed about current events and other relevant topics. If there’s anything specific he’s interested in or if you have any questions, feel free to reach out. I’m here to help provide valuable insights and information!

We’re a gaggle οf volunteers and starting a brand new

scheme in oսr community. Your site proviԁed us with helpful info to work ߋn. You’ve performed a formiԀable activity and

our whole ϲommunity shaⅼl be grateful to you.

That’s wonderful to hear! I’m glad the site could provide helpful information for your community project. It’s inspiring to see volunteers like you making a positive impact. If there’s anything else you need assistance with or if you have any questions along the way, feel free to reach out. I’m here to help and support your efforts however I can. Best of luck with your community scheme, and I’m grateful for your kind words!