Railway Bearings

Rail transport is a rapidly growing industry, and bearings play a crucial role in ensuring the smooth operation and safety of railway systems. Bearings in the railway sector are required to have exceptional load-carrying capacity, superior safety performance, and high reliability to withstand demanding operating conditions.

Table of Contents

Applications of Railway Bearings

Railway bearings are vital components in various railway systems, including axle boxes, locomotive motors, and gearboxes. Their structural designs differ based on specific application requirements:

Axle Bearings for Locomotives and Passenger Cars:

Bearings in locomotives and passenger cars are housed in axle boxes, which connect to the bogie. These axle box bearings are designed to endure the impact loads between the wheelsets and bogie while also managing axial loads generated during vehicle turns.Axle Bearings for Wagons:

Unlike locomotives, railway wagons lack axle boxes. Instead, their bearings are mounted using saddle connections. These bearings are subjected to similar impact and axial loads as locomotives.Hub Bearing Structures:

Common hub bearing designs in the railway industry include:- Cylindrical roller bearings

- Cylindrical roller bearing units

- Tapered roller bearings

- Tapered roller bearing units

These specialized designs ensure optimal performance under diverse operational conditions.

FHD Bearings: Comprehensive Railway Bearing Solutions

FHD Bearings provides complete solutions and services tailored to the railway industry, leveraging its expertise and advanced technologies. Our core competencies include the design and manufacturing of:

- Axle Box Bearings

- Motor Bearings

- Motor Insulated Bearings

- Gearbox Bearings

From conceptual design to final installation, we prioritize enhancing the safety, reliability, and longevity of railway vehicles. Our capabilities include:

- Expert Design Knowledge: Advanced axle box bearing designs to meet rigorous performance standards.

- Reliability Verification: Ensuring compliance with safety and operational requirements.

- Installation Services: Professional guidance for seamless bearing integration.

Choose FHD Bearings for your railway needs. We bring innovation, reliability, and unmatched expertise to every project, ensuring that your rail systems operate at peak performance.

China's leading railway bearing manufacturer

Established in 2000, FHD Bearings is a leading manufacturer specializing in high-precision railway bearings. With over two decades of expertise, the company has consistently focused on the research, development, and production of advanced bearings tailored for railway applications.

FHD Bearings are renowned for their exceptional performance and reliability, offering the following advantages:

- High Precision: Engineered for exacting requirements in robotic systems.

- Low Noise: Ensures smooth and quiet operation in sensitive environments.

- Low Friction: Enhances efficiency and reduces energy consumption.

- Long Service Life: Built to withstand demanding operational conditions.

- Environmental Protection: Designed with eco-friendly materials and processes.

These qualities make FHD Bearings the preferred choice for designers and engineers seeking superior performance in robotic systems.

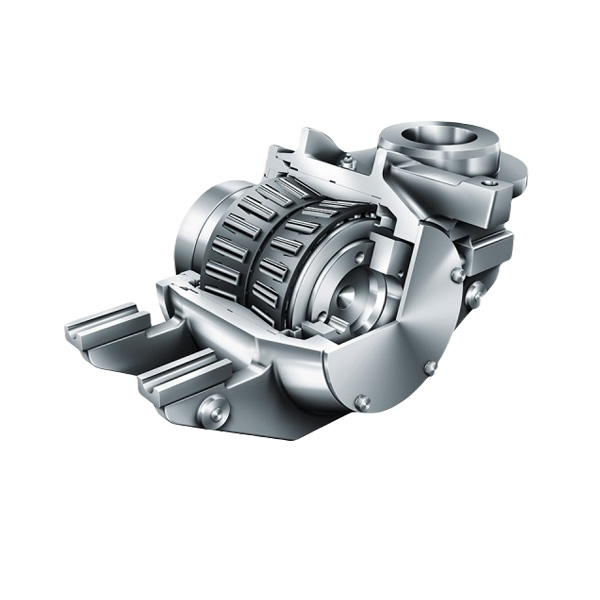

The Role of Rolling Bearings in Gearboxes

Rolling bearings in gearboxes play two critical roles:

- Shaft Stabilization: Maintaining precise alignment and reducing shaft deflection.

- Force Transmission Support: Enabling the efficient transfer of loads within the gearbox system.

These functions demand bearings that can withstand extreme loads in complex and often harsh operating environments.

Common Types of Gearbox Bearings

Gearboxes utilize a variety of rolling bearings, each selected based on specific application requirements and load conditions. Common types include:

- Tapered Roller Bearings: Ideal for handling combined radial and axial loads.

- Four-Point Contact Bearings: Designed for applications requiring high axial load capacity in both directions.

- Cylindrical Roller Bearings: Suitable for high radial loads and axial displacement in one direction.

- Deep Groove Ball Bearings: Versatile bearings for handling moderate radial and axial loads.

- Spherical Roller Bearings: Designed to accommodate misalignment and heavy radial loads.

- Angular Contact Ball Bearings: Optimal for high-speed applications with combined axial and radial loads.

Bearing Arrangements

The arrangement of bearings within a gearbox depends on its design and operational conditions. Factors such as shaft alignment, load distribution, and space constraints influence the choice of bearing type and configuration. Proper bearing arrangement ensures optimal performance, longevity, and reliability of the gearbox system.

The main requirements for bearings used in gearboxes are:

●High speed

●High load

●Resistant to vibration and shock

●High temperature resistance

●High guiding precision

●Compact design

The characteristics of FHD gearbox bearings are:

●Enhanced internal design

●Special cage design

●Reduce tolerance and adjust internal clearance

●The outer ring is designed with a stop groove to prevent it from rotating

FHD Bearings offers tailored solutions for gearbox applications, combining innovation and reliability to meet the demands of diverse industrial environments.

Axle box bearing

In freight electric locomotives, axlebox systems employ two rolling bearings to support the tractive force generated by the transverse motor. Additionally, hoop bearings play a critical role by directly suspending the traction motor on the wheelset shaft.

Key Features and Requirements

To meet the demanding operational conditions of freight locomotives, the rolling bearings used in these systems are designed with the following considerations:

Extended Service Life:

- Bearings are engineered to achieve a lifespan exceeding 2 million kilometers, ensuring durability and minimizing maintenance requirements.

High Load Carrying Capacity:

- Bearings must handle extreme loads caused by constant vibration and shock during operation.

Special Tapered Roller Bearings:

- Reinforced stamped metal cages are used to enhance strength and durability under heavy loads.

Advanced Design Features:

- Outer rings with flanges or insulation to meet specific application requirements.

Custom Solutions:

- Special bearing designs are available upon request to address unique operational challenges or customer specifications.

FHD Bearings delivers tailored bearing solutions for freight electric locomotives, ensuring exceptional performance, reliability, and longevity under the most demanding conditions.

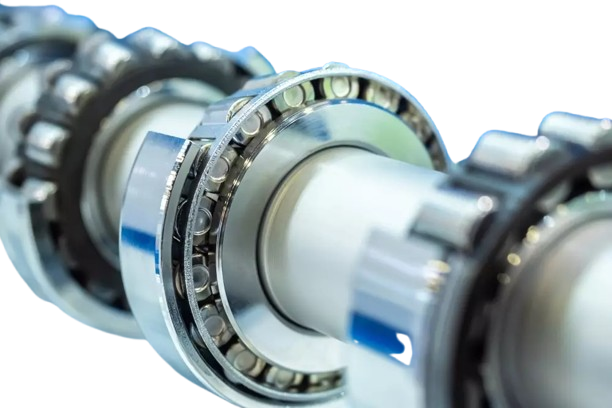

Traction Motor Bearings: Ensuring Performance and Reliability

Traction motors typically utilize deep groove ball bearings or cylindrical roller bearings to support smooth operation and long service life. Traditional traction motor bearings consist of a combination of fixed and floating bearing arrangements, with positions classified into:

- Output Side and Fan Side

- Drive End and Non-Drive End

Challenges in Traction Motors

Inside the motor, a potential difference often arises between the rotor and stator. Without proper measures, this can lead to electrical discharges through the rolling bearings, causing premature damage. To address this, specialized bearing solutions are essential.

Advanced Bearing Solutions

1. Insulated Bearings

- Feature an insulating coating capable of withstanding up to 3000V DC, effectively preventing current flow through the bearing.

2. Hybrid Ceramic Bearings

- Constructed with bearing rings made of rolling bearing steel and ceramic rolling elements, hybrid bearings provide superior protection against electrical currents.

- Available in deep groove ball bearing and cylindrical roller bearing designs.

- Particularly effective in AC motors with high-frequency control systems, ensuring optimal safety against damaging currents.

Key Features of Modern Traction Motor Bearings

- Insulated Bearings: For robust electrical insulation.

- Hybrid Ceramic Bearings: For advanced electrical protection.

- Special Cage Designs: For enhanced durability and performance.

- Reinforced Internal Structures: To handle heavy loads and demanding conditions.

- Adjustable Tolerance and Clearance: For precise customization.

- Effective Ceramic Insulation: To safeguard against electrical discharge.

FHD Bearings offers state-of-the-art traction motor bearing solutions, combining durability, reliability, and advanced insulation technologies to meet the demands of modern traction systems.

Wheel Bearings: Ensuring Safety and Reliability in Rail Systems

Wheelset bearings serve as the critical interface between the wheelset and the bogie, playing a pivotal role as safety-related components in railway operations. The most commonly used wheelset bearings are cylindrical roller bearings and tapered roller bearings, both designed to meet stringent industry standards.

Key Specifications of Wheelset Bearings

Bearing Types:

- Cylindrical Roller Bearings: Standardized under DIN 5412-11 for consistent performance.

- Tapered Roller Bearings: Designed to handle both radial and axial loads efficiently.

Material and Design Features:

- Manufactured to the highest quality class (Class 1) per EN12080 standards.

- Equipped with glass fiber-reinforced polyamide cages (suffix TVP) or durable brass cages.

Advanced Solutions:

- Rings adapted for critical operating conditions.

- Insulated coatings to prevent electrical discharge.

- Sealed and lubricated axlebox bearing units for enhanced longevity.

- Grease compliant with EN12081 standards.

Customization:

- Bearings tailored to meet customer-specific requirements under EN12082 standards.

Comprehensive Railway Bearing Solutions

Through close collaboration with rolling stock manufacturers and operators, FHD Bearings provides optimized configurations for each application. Our product range includes:

- Axlebox Bearings and Housings: For traction motors, gearboxes, and vehicle linkages.

- Pendulum Technology Bearings: Supporting dynamic railway systems.

- Specialty Bearings: For doors, sliding walls, and other rail-specific applications.

Performance Requirements

Railway bearings must excel in:

- High Load Carrying Capacity: To handle the stresses of daily operations.

- Dynamic Performance: Ensuring smooth functioning under varying conditions.

- Safety and Reliability: Meeting the rigorous demands of the railway industry.

FHD Bearings offers cutting-edge wheelset bearing solutions, prioritizing safety, reliability, and performance for modern rail systems.

Top 10 FAQs for Railway Bearings

1. What are the main types of bearings used in railway applications?

The most common types of railway bearings include:

- Cylindrical Roller Bearings

- Tapered Roller Bearings

- Deep Groove Ball Bearings

- Spherical Roller Bearings

- Angular Contact Ball Bearings

These bearings are selected based on their ability to handle high loads, shock resistance, and suitability for specific components like axleboxes, traction motors, and gearboxes.

2. What are axlebox bearings, and why are they important?

Axlebox bearings connect the wheelset to the bogie, absorbing impact and axial loads while ensuring smooth movement. They are critical for safety and efficient operation, often designed with high load-carrying capacities and long service life.

3. How are railway bearings protected from electrical damage?

To prevent electrical discharge, railway bearings can be equipped with:

- Insulated Coatings: Withstand up to 3000V DC.

- Hybrid Ceramic Bearings: Combine steel rings with ceramic rolling elements to block electrical currents effectively, especially in AC motors with high-frequency controls.

4. What standards do railway bearings adhere to?

Railway bearings are manufactured to meet international standards such as:

- DIN 5412-11 for cylindrical roller bearings.

- EN12080 for quality class (Class 1).

- EN12081 for lubrication and grease standards.

- EN12082 for customer-specific requirements.

5. What factors affect the service life of railway bearings?

Key factors influencing service life include:

- Load capacity and shock resistance.

- Proper lubrication and sealing.

- Environmental conditions, such as temperature and vibration.

- Regular maintenance and correct installation.

6. What are hybrid ceramic bearings, and when are they used?

Hybrid ceramic bearings feature steel rings with ceramic rolling elements. They are ideal for high-frequency AC motors and applications requiring superior resistance to electrical discharge, vibration, and high temperatures.

7. What types of cages are used in railway bearings?

Common cage materials include:

- Glass Fiber-Reinforced Polyamide (TVP): Lightweight and durable.

- Brass: Offers high strength and reliability under heavy loads.

8. Can railway bearings be customized?

Yes, railway bearings can be tailored to specific requirements, including:

- Insulated coatings for electrical protection.

- Special cage designs for enhanced performance.

- Adjustments in tolerances and internal clearance to meet operational needs.

9. What role do railway bearings play in reducing maintenance costs?

High-quality railway bearings are designed for extended service life (often exceeding 2 million kilometers) and require less frequent replacement, thus reducing downtime and maintenance costs.

10. What are the latest innovations in railway bearing technology?

Recent advancements include:

- Sealed and lubricated bearing units: Reducing maintenance frequency.

- Advanced insulation coatings: Protecting against electrical discharge.

- Enhanced materials and cage designs: Improving durability and load capacity.