Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

How Angular Contact Ball Bearings Perform

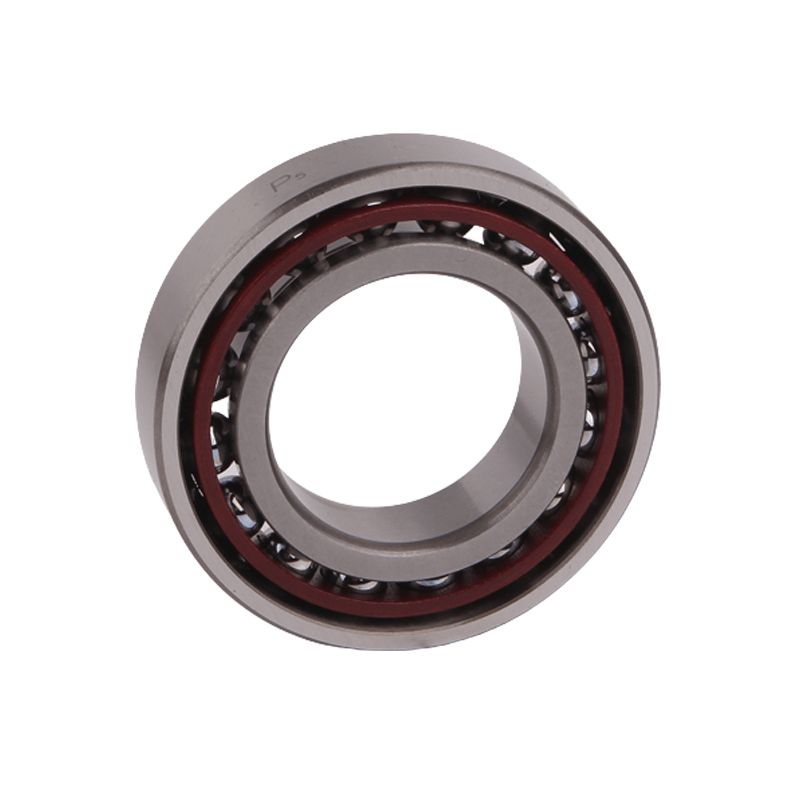

In the arena of modern mechanical engineering, angular contact ball bearings have become one of the stars of engineering design by virtue of their outstanding performance. This type of bearing is not just an evolution of the traditional rolling bearing, it is an engineering leap forward. Their unique design structure allows them to excel in high-speed rotating, complex load environments. This article will provide an in-depth analysis of the performance characteristics of angular contact ball bearings, discussing their key role in mechanical systems and how they have become a symbol of durability and efficiency in a variety of fields.

Inner and outer ring construction:

Inner ring (inner ring): the inner ring of angular contact bearings is usually mounted on the shaft, it has one or more raceways, so that the rolling elements can roll inside it.

Outer ring (outer ring): and the inner ring, the outer ring of the raceway and the inner ring correspond to each other, forming a complete bearing structure.

Raceway design:

Raceways are grooves in the inner and outer rings that are unique in that they are at an angle to the axis of the bearing, usually a diagonal line connecting the rolling elements. This angle allows the bearing to withstand both radial and axial loads.

Rolling bodies:

The rolling bodies of angular contact bearings are usually spherical, and these spheres are designed to be tangential to the raceways of the inner and outer rings so that they roll smoothly when the bearing is in operation. This design allows the bearing to have a higher load capacity and lower coefficient of friction.

Cage:

Cage is located between the rolling elements, its main role is to maintain the relative position of the rolling elements, to prevent them from colliding with each other and friction. Common cage materials include steel and nylon, etc.

Angle design:

Unlike other rolling bearings, angular contact bearings are designed with an angle that enables it to maintain axial rigidity while bearing loads. This characteristic is especially important in applications requiring high precision and rigidity.

Sealing and lubrication:

Angular contact bearings are usually equipped with seals to prevent dust and impurities from entering the inside of the bearing and affecting its working effect. Appropriate lubrication is also the key to ensure the long-term stable operation of bearings.

Bidirectional load bearing:

Due to their angular design, angular contact bearings are able to withstand radial and axial loads at the same time, which makes them perform well in the case of bidirectional load bearing. This provides greater flexibility in the design of complex engineering systems.

Material selection:

Angular contact bearings are often made of high-strength, highly wear-resistant materials such as chrome steel or stainless steel to ensure their long life and stability under high loads and high speeds.

Superior performance characteristics of contact ball bearings

High load capacity:

Angular contact ball bearings are designed to withstand both radial and axial loads and still maintain excellent performance at high speeds. This feature makes it excel in industrial equipment and mechanical systems that are subject to heavy loads.

Accurate positioning ability:

Due to its special angular design, the angular contact bearing can provide more accurate locating ability. This allows it to excel in applications that require high-precision positioning, such as machine tools and industrial robots.

High-speed rotational performance:

The design structure of angular contact ball bearings and the selection of high-strength materials make it perform excellently at high speed rotation. This characteristic makes it in the requirement of high-speed operation of industrial equipment and automobile transmission system in a wide range of applications.

Strong rigidity:

Its design angle enhances the support of axial rigidity to ensure that good structural rigidity is maintained in the mechanical system. This characteristic is essential to ensure that the equipment does not deform when the load changes.

Bidirectional load carrying capacity:

Angular contact bearings are not only able to withstand radial loads, but also able to cope with axial loads, making them superior in complex load situations. This feature provides more options for design flexibility.

High precision:

Angular contact ball bearings are designed and manufactured with a high degree of angular precision, enabling them to provide high precision movement. This makes it ideal in scenarios where high precision work is required, such as precision instruments and medical equipment.

Low friction and high efficiency:

Due to the use of high quality lubrication materials and design, angular contact bearings are able to achieve low friction motion. This not only reduces energy consumption, but also extends bearing life.

Versatile applications:

Due to their comprehensive performance characteristics, angular contact ball bearings have a wide range of applications in various fields, including machinery manufacturing, automotive, aerospace, etc., providing stable and reliable support for engineering systems in different industries.

Areas Of Application

- Machine tools and industrial robots:

In machine tools and industrial robots, high precision and accurate positioning are key requirements. Angular contact ball bearings are widely used in robotic arms, slide tables, and the spindle and guideway systems of all types of precision machine tools because of their ability to provide high-precision, high-rigidity motion.

- Automotive transmission system:

In the automotive field, angular contact ball bearings are often used in the transmission system, including differentials, wheel hubs, drive shafts and other parts. Their high load capacity and high speed rotary performance ensure that the automobile maintains smooth operation at high speeds and under complex road conditions.

- Aerospace field:

In aerospace engineering, high load bearing capacity and high precision are required for components. Angular contact ball bearings are often used in aircraft engines, landing gear, navigation systems and other key parts to ensure the reliability and stability of the aircraft in extreme environments.

- Medical equipment:

In the field of medical equipment manufacturing, the high precision and high efficiency of the equipment put forward strict requirements. Angular contact ball bearings play a key role in medical imaging equipment, surgical robots and other equipment to ensure smooth movement and high precision.

- Power engineering:

In power engineering, equipment such as wind turbines and turbine generators have high requirements for withstanding complex loads and high speed rotations. Angular contact ball bearings are widely used in the rotor support and high-speed rotation bearing position of these equipments.

- Machinery manufacturing:

In the field of machinery manufacturing, all kinds of mechanical equipment need to withstand different working conditions of the load, and angular contact ball bearings with its multi-functional characteristics, widely used in machine tools, pumps, fans and other production equipment.

- Rail transportation:

In the field of rail transportation, such as high-speed railway and subway and other means of transportation of high-speed operation for bearings put forward high requirements. Angular contact ball bearings play a key role in wheels, transmission system and other parts to ensure the safe and efficient operation of transportation.

- Energy field:

In the energy industry, angular contact ball bearings are widely used in all kinds of turbines, generators and other equipment, and their superior performance characteristics provide solid support for the reliable operation of energy equipment.

How to Maintain

- Regular lubrication:Proper operation of angular contact ball bearings depends on adequate lubrication. Regularly check the lubrication of the bearings to ensure that the proper grease or oil is used and that it is changed periodically in accordance with the manufacturer’s recommendations.

- Seal protection:Inspect the seals of the bearings to ensure that they are in good condition. The presence of seals can effectively prevent dust, impurities and moisture from entering the inside of the bearings and improve the durability of the bearings.

- Temperature monitoring:

Regularly monitor the operating temperature of the bearings. Abnormally elevated temperatures can be a sign of bearing problems. Timely detection and resolution of the problem can effectively prevent further damage.

- Vibration and noise detection:

Regularly check bearing vibration and noise levels. Abnormal vibration and noise may indicate a bearing problem that requires prompt investigation and repair.

- Mounting and adjustment:

When mounting the bearings, ensure that they conform to the proper mounting guidelines provided by the manufacturer. Correct mounting will minimize the extra load on the bearings and ensure their proper operation.

- Periodic cleaning:

Clean the bearing and its surrounding area regularly. Removing dust and impurities and keeping the surrounding environment clean can effectively prevent bearing damage and reduced life.

- Regular inspection of accessories:

Regularly check the bearing-related fittings, such as cages and seals. Ensure that they are not cracked, deformed or otherwise damaged to guarantee the normal operation of the bearings.

- Suitable loads:

Avoid the bearings being subjected to overloaded working conditions. Ensure that the load is within the rated load range of the bearings to prevent premature wear and damage to the bearings.

- Use of correct tools:

Use proper tools during maintenance and installation. Avoid using improper tools that may cause damage to the bearing and affect its performance.

- Regular inspection of the tracks:

The track of angular contact ball bearings may wear out during use. Regularly check the condition of the tracks, and if any abnormality is found, take timely measures to repair or replace them.

References

1.“Ball Bearings” from Wikipedia;

4. “Angular contact ball bearings” from SKF;