Categories

The Versatility And Impact Of Ball Bearings

Table of Contents

Ball bearings, although basic but often overlooked, play a vital role in a variety of industries. This article takes an in-depth look at the basic construction of ball bearings and how they are used in a wide range of applications

Ball Bearing Basics

Structure and components

A ball bearing is an important mechanical element with a simple and delicate construction. It mainly consists of an inner ring, an outer ring and a ball located between the two.

- Inner and outer rings:

The inner and outer rings are the main support structure of the ball bearing. The inner ring is a ring-shaped part mounted on the shaft, while the outer ring is fitted with the inner ring and supported as a whole on the bearing housing. This construction design enables the bearing to withstand radial and axial loads. - Balls:

The balls are the key component in a ball bearing and are located between the inner and outer rings. These small balls, usually made of high-quality steel, reduce friction by reducing the surface area in contact with the inner and outer rings, thereby improving the operating efficiency of the bearing.

Functional principle analysis

- The operating principle of ball bearings is based on the concept of rolling friction, specifically the rolling of balls between the inner and outer rings. This design significantly reduces friction and heat generation compared to plain bearings, making mechanical systems more efficient.

- When the equipment in which the bearing is located is started, the balls between the inner and outer rings begin to roll. Due to the rolling characteristics, friction is greatly reduced compared to sliding, thus reducing energy losses. This not only extends the service life of the bearing, but also increases the efficiency of the entire mechanical system.

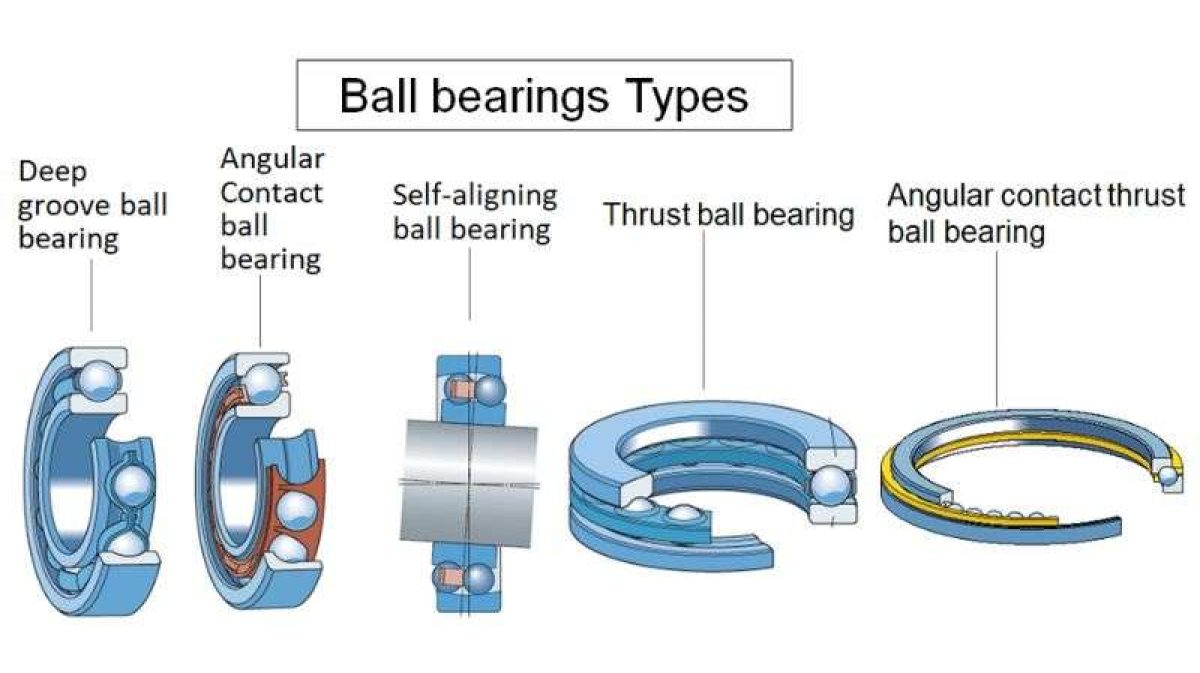

Different types of ball bearings

- Deep Groove Ball Bearings

Deep groove ball bearings are one of the most common types and have deep raceways that allow them to withstand large radial and axial loads. This design is particularly suitable for high-speed machines such as power tools and electric motors. - Angular contact ball bearings

Angular contact ball bearings are designed to help withstand large axial loads. They are often used in equipment that needs to support movement on an axle, such as the front wheel section of an automobile. - Self-aligning ball bearings

Self-aligning ball bearings allow the shaft to be deflected at an angle in different directions and are suitable for use where there is some axial misalignment in the assembly. This makes them ideal for use in applications where axial misalignment needs to be compensated, such as vibrators and fans. - Thrust ball bearings

Consists of two washers and a ball assembled in a cage.

Designed to withstand unidirectional axial loads, they are commonly used in applications with axial loads, such as thrust loads in automotive steering systems and gearboxes. Ideal for applications requiring high axial load capacity.

Widely Used Ball Bearings In Various Industries

1.Role in the Automotive Industry

Wheel bearings:One of the most common applications of ball bearings in the automotive industry are wheel bearings. They support all the weight of the vehicle and allow the wheels to rotate freely. The high load capacity and low friction properties make ball bearings an integral part of automotive design.

Driveline:In automotive drivelines, ball bearings are used to support various rotating components such as drive shafts and clutches. This helps to reduce friction losses in the system and increase transmission efficiency, while ensuring the stability and reliability of the entire system.

Engine components:Components in automotive engines, such as generators, fans and water pumps, also rely on ball bearings to ensure their efficient operation. The durability and high-speed capability of ball bearings make them highly desirable in these critical components.

2.Applications in the Aviation Industry

Aircraft engines: In the aerospace sector, ball bearings play a vital role in aircraft engines. They are used to support high-speed rotating engine components such as turbines and fans. Their high precision and high temperature resistance enable them to withstand extreme operating conditions.

Rudders and flaps: An airplane’s rudder and flaps also use ball bearings to ensure their smooth movement. This is critical to the maneuvering and control of the aircraft, and the low friction and high reliability of ball bearings make them ideal for these critical systems.

Landing gear: Ball bearings in an airplane’s landing gear carry enormous loads and need to absorb shock during landing. Their high load carrying capacity and resistance to vibration make ball bearings vital in this critical component.

3.Industrial Machinery

Production line equipment: In the field of industrial machinery, ball bearings are widely used in production line equipment such as conveyor belts and rollers. Their ability to withstand high loads and speeds enables these machines to run smoothly, thus increasing productivity.

Robotic arms and robots: Ball bearings are commonly used in the joints of industrial robotic arms and robots to achieve precise and flexible movements. Their high precision and low friction allow robots to perform complex tasks, resulting in increased automation.

Tools and equipment: Various tools and equipment, such as power tools and production equipment, also make extensive use of ball bearings. Their stability and efficiency enable these tools to operate reliably under a wide range of operating conditions.

Advantages ball bearings

Ball bearings, as key components in mechanical systems, have many advantages that make them highly desirable in a variety of applications

- Reduced friction

The design of ball bearings allows the balls to roll between the inner and outer rings instead of sliding, which greatly reduces friction. Compared to plain bearings, this rolling design not only reduces energy losses but also lowers the operating temperature of the system. This design not only improves efficiency, but also extends the service life of ball bearings. - Increased durability

Ball bearings are made of high-quality materials that have excellent strength and hardness. This enables the ball bearings to withstand high loads and remain stable at high speeds. This durability means that ball bearings maintain excellent performance in a wide range of operating conditions, reducing the need for system maintenance and lowering operating costs. - Motion transfer efficiency

The efficiency of motion transfer in mechanical systems is increased due to the reduced friction caused by ball bearings. This is critical in many applications, especially in scenarios where high precision and efficiency are required, such as robots, production lines and high-speed transfer equipment. The high efficiency of ball bearings helps to save energy and improve overall system performance. - Accuracy and controllability

Ball bearings are designed and manufactured with a focus on accuracy to ensure consistent performance during operation. This makes ball bearings ideal for applications that require a high degree of precision control, such as industrial robotic arms, aerospace equipment and medical devices.

- Versatile applications

Due to their flexibility in construction, ball bearings are suitable for a wide range of application scenarios. Different types of ball bearings can be selected for different needs, including deep groove ball bearings, angular contact ball bearings and self-aligning ball bearings. This makes ball bearings a versatile solution in many industries, meeting the needs of different applications. - Low noise and smooth running

The rolling design of ball bearings allows them to operate with relatively low noise. This is particularly important for applications that require a low-noise environment, such as household appliances, automobiles and medical equipment. In addition, the smooth operation of ball bearings helps to minimize vibration, further improving system stability. - Simplified maintenance

The relatively simple structure of ball bearings makes maintenance relatively easy. This reduces maintenance costs and maintenance times, making them more feasible in a wide range of applications. Simplified maintenance processes also mean less downtime for the system and increased equipment availability.

Factors Affecting Selection

1. Load capacity:Considering the radial and axial loads carried in the system, the load capacity of the ball bearings should be selected to meet the actual requirements.

2. Speed requirement:Considering the operating speed of the system, select ball bearings that can meet the requirements of high-speed operation.

3. Operating environment:Considering the conditions of the working environment, such as temperature, humidity and corrosion, select the ball bearing with high temperature and corrosion resistance.

4. Mounting space:Make sure that the size and structure of the ball bearings are adapted to the available mounting space to ensure proper mounting and operation.

5. Budget and cost-effectiveness:While considering the performance, make sure the selected ball bearings meet the requirements of budget and cost-effectiveness.

Maintenance Considerations

1. Lubrication requirements:Determine the lubrication requirements of the system and select a suitable lubrication program, such as oil or grease lubrication.

2. Maintenance cycle:Considering the maintenance cycle of ball bearings, choose the model that can meet the system requirements and has lower maintenance requirements.

3. Ease of replacement:In case of possible replacement, select ball bearings with simple design and easy replacement to minimize maintenance time.

Conclusion

Ball bearings play an indispensable role in various industries as key components in mechanical engineering. Their advantages include reduced friction, increased durability, high motion transfer efficiency, precise control, diverse applications, low noise and smooth operation, as well as simplified maintenance. Ball bearings are designed and used in a wide range of applications, and through an in-depth understanding of their construction, function, advantages, as well as the main points of selection and maintenance, they can be better applied to various industries, improve system performance, reduce maintenance costs, and promote the continuous advancement of science, technology and engineering.