Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Ball Bearings vs. Roller Bearings: A Comprehensive Comparison

Introduction

Construction and Design

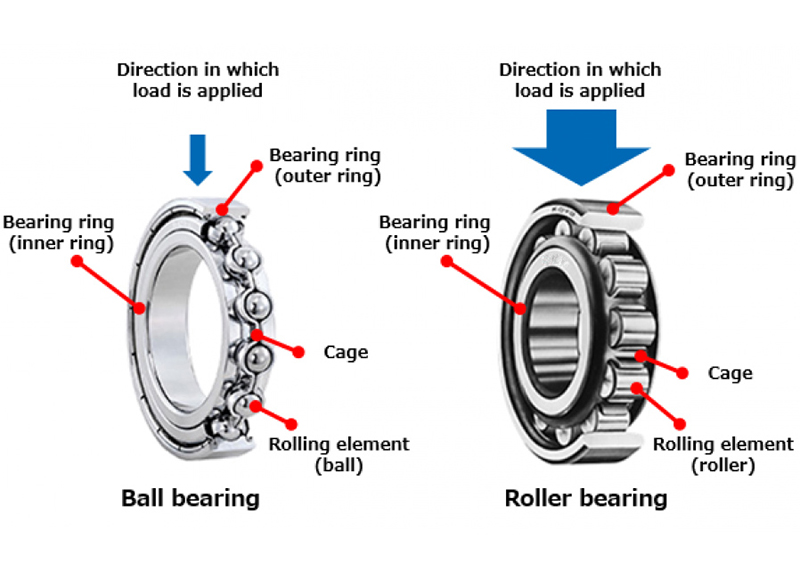

Construction and Design: Ball bearings and roller bearings differ significantly in their construction and design, influencing their performance and suitability for various applications. Ball bearings typically consist of inner and outer rings with a set of balls sandwiched between them. These balls, usually made of steel or ceramic, enable smooth rolling motion and minimize friction. Depending on the specific application requirements, ball bearings come in various types such as deep groove and angular contact bearings, each designed to accommodate different loads and operating conditions.

On the other hand, roller bearings feature cylindrical, tapered, or spherical rollers instead of balls. These rollers provide a larger contact surface area, distributing loads more evenly and allowing roller bearings to handle heavier loads compared to ball bearings. Additionally, roller bearings are designed to withstand axial and radial forces, making them suitable for applications with high load demands, such as heavy machinery and industrial equipment. Understanding the construction and design nuances of ball bearings and roller bearings is crucial for selecting the most appropriate bearing type for specific operational needs and performance requirements.

Working Principle

Ball Bearings

Ball bearings operate on the principle of rolling motion to reduce friction between moving parts. The inner and outer rings, separated by a series of balls, allow for smooth rotation with minimal resistance. As the inner ring rotates, the balls roll along the raceways of both rings, significantly decreasing the friction compared to sliding motion. This design enables ball bearings to support both radial and axial loads while maintaining high rotational speeds. The efficiency of ball bearings in minimizing friction makes them ideal for applications requiring precision and speed, such as in electric motors, household appliances, and automotive components. Understanding this fundamental working principle helps in selecting the right ball bearing for specific performance needs.

Roller Bearings

Roller bearings operate by utilizing cylindrical, tapered, or spherical rollers between the inner and outer rings to reduce friction and support loads. These rollers provide a greater contact area compared to balls, allowing roller bearings to handle higher radial and axial loads more effectively. As the inner ring rotates, the rollers roll along the raceways, distributing the load over a larger surface area and minimizing stress concentrations. This design makes roller bearings particularly suitable for heavy-duty applications where high load capacity and durability are crucial, such as in industrial machinery, conveyors, and heavy equipment. Understanding the working principle of roller bearings is essential for choosing the appropriate bearing to ensure optimal performance and longevity in demanding environments.

Load Capacity

The load capacity of ball bearings and roller bearings differs significantly, impacting their suitability for various applications. Ball bearings are designed to handle moderate loads and are particularly effective in applications requiring high-speed rotation. The spherical shape of the balls minimizes contact with the raceways, resulting in lower friction and enabling smoother and faster operation. This makes ball bearings ideal for precision instruments, electric motors, and other devices where speed and accuracy are paramount. However, their ability to carry heavy loads is limited compared to roller bearings.

In contrast, roller bearings are designed to handle much higher load capacities due to their larger contact area with the raceways. The cylindrical, tapered, or spherical rollers distribute the load more evenly across the bearing, allowing roller bearings to support both radial and axial loads efficiently. This makes them suitable for applications involving heavy machinery, such as construction equipment, conveyor belts, and industrial machines, where the ability to bear substantial loads without compromising performance is essential. Understanding the load capacity differences between ball bearings and roller bearings is crucial for selecting the appropriate bearing type to ensure optimal performance, reliability, and longevity in various mechanical systems.

Speed and Performance

The speed and performance characteristics of ball bearings and roller bearings are key factors in determining their suitability for different applications. Ball bearings are known for their high-speed capabilities due to the low friction generated by the point contact between the balls and the raceways. This design allows for smoother and faster rotation, making ball bearings ideal for applications that demand precision and high rotational speeds, such as in electric motors, fans, and precision instruments. The lower friction also results in less heat generation, contributing to the efficient performance of ball bearings in high-speed environments.

On the other hand, roller bearings, with their line contact between the rollers and raceways, offer enhanced stability and load distribution but typically operate at lower speeds compared to ball bearings. The larger contact area in roller bearings can generate more friction, which may limit their speed capabilities. However, this design provides superior performance in handling heavy loads and resisting shock and impact, making roller bearings suitable for applications where durability and load-bearing capacity are critical, such as in industrial machinery, heavy equipment, and automotive applications. Understanding the differences in speed and performance between ball bearings and roller bearings is essential for selecting the appropriate bearing to meet specific operational demands and ensure optimal functionality.

Application Areas

The application areas of ball bearings and roller bearings are diverse, reflecting their unique characteristics and performance capabilities. Ball bearings are widely used in applications requiring high precision, low friction, and high-speed operation. They are commonly found in the automotive industry, where they are used in wheels, engines, and transmissions. Additionally, ball bearings are essential in electric motors, household appliances, and various types of machinery that demand smooth, efficient rotation at high speeds. Their ability to support both radial and axial loads while maintaining accuracy and stability makes them suitable for a broad range of precision instruments and devices.

Conversely, roller bearings excel in applications that demand high load-bearing capacity and durability. They are particularly effective in heavy-duty machinery and industrial equipment, such as construction machinery, conveyor systems, and mining equipment, where they can support substantial radial and axial loads. Roller bearings are also prevalent in agricultural machinery, railroad applications, and large-scale industrial operations, where robust performance and longevity are critical. The design of roller bearings allows them to distribute loads more evenly and withstand harsh operating conditions, making them indispensable in environments where reliability and strength are paramount. Understanding the distinct application areas of ball bearings and roller bearings helps in selecting the right bearing type to ensure optimal performance and longevity in various industrial and mechanical systems.

Durability and Longevity

Durability and longevity are critical considerations when choosing between ball bearings and roller bearings. Ball bearings, with their smooth, spherical elements, are designed to minimize friction and wear under normal operating conditions. However, in high-load situations, the smaller contact area of the balls can lead to higher stress concentrations, potentially reducing their lifespan if not properly maintained. Regular lubrication and maintenance are essential to ensure the durability and long-term performance of ball bearings, particularly in high-speed applications where heat generation can be a concern.

In contrast, roller bearings are inherently more durable and capable of withstanding heavy loads and harsh conditions due to their larger contact surface area. The cylindrical, tapered, or spherical rollers distribute loads more evenly, reducing stress on individual components and enhancing the overall longevity of the bearing. This makes roller bearings highly suitable for demanding environments such as industrial machinery, construction equipment, and transportation systems, where they are exposed to significant radial and axial forces. Their robust design allows for longer service intervals and less frequent maintenance compared to ball bearings. Understanding the durability and longevity differences between ball bearings and roller bearings is essential for making informed decisions about bearing selection to ensure reliable and cost-effective operation over time.

Installation and Maintenance

The installation and maintenance of ball bearings and roller bearings play a vital role in their performance and longevity. Ball bearings are generally easier to install due to their simpler design and smaller size. They often come pre-lubricated, reducing the initial setup time. However, to maintain optimal performance, ball bearings require regular lubrication and periodic inspections to check for wear and tear, especially in high-speed applications where friction can generate significant heat. Proper installation and maintenance ensure that ball bearings function smoothly and last longer, making them suitable for applications where ease of maintenance is a priority.

Roller bearings, on the other hand, can be more challenging to install due to their larger size and more complex design. Precise alignment is crucial during installation to prevent uneven load distribution, which can lead to premature failure. Maintenance of roller bearings also tends to be more demanding, involving regular lubrication and detailed inspections to monitor the condition of the rollers and raceways. Despite the more intensive maintenance requirements, roller bearings offer superior durability and load-bearing capacity, making them ideal for heavy-duty applications where reliability is critical. Understanding the differences in installation and maintenance between ball bearings and roller bearings helps in selecting the right bearing type to ensure efficient operation and long-term reliability in various mechanical systems.

Noise and Vibration

Noise and vibration levels are important factors to consider when choosing between ball bearings and roller bearings, as they can significantly impact the performance and comfort of machinery and equipment. Ball bearings, with their point contact design, typically operate more quietly and with less vibration compared to roller bearings. The smooth rolling action of the balls minimizes contact area and friction, resulting in lower noise levels, which is advantageous in applications where quiet operation is essential, such as in household appliances, electric motors, and precision instruments.

In contrast, roller bearings, which have line contact between the rollers and raceways, can generate more noise and vibration due to the larger contact area. This is particularly true under high load conditions where the interaction between the rollers and raceways can produce noticeable vibrations. However, modern roller bearing designs have incorporated various features to reduce noise and vibration, such as optimized roller geometry and improved materials. Despite these advancements, roller bearings are still generally louder and more prone to vibration than ball bearings. They are typically used in applications where noise is less of a concern and where their ability to handle heavy loads and absorb shocks is more critical, such as in industrial machinery and construction equipment. Understanding these differences helps in selecting the right bearing type to meet specific noise and vibration requirements.

Cost Comparison

Initially, ball bearings tend to have a lower upfront cost compared to roller bearings, primarily due to their simpler design and manufacturing process. This makes ball bearings more economically viable for applications with lower load requirements and where precision is crucial, such as in small motors and consumer electronics. However, it’s essential to consider the long-term cost implications, as roller bearings often offer better durability and longer service life, resulting in lower maintenance and replacement costs over time. Roller bearings can withstand heavier loads and harsher operating conditions, reducing the frequency of replacements and repairs, which can offset their higher initial cost. Additionally, the specific requirements of the application, such as load capacity, speed, and environmental factors, should be carefully evaluated to determine the most cost-effective bearing solution in the long run. Therefore, while ball bearings may offer a more affordable initial investment, roller bearings may prove to be a more cost-efficient option in applications where durability and longevity are paramount.

Conclusion

In conclusion, the choice between ball bearings and roller bearings hinges on understanding their distinct characteristics and performance attributes. Ball bearings excel in high-speed, precision applications, offering lower friction and quieter operation. Conversely, roller bearings are ideal for heavy-duty machinery, providing superior load capacity and durability. While ball bearings may be more cost-effective upfront, roller bearings often offer better long-term value due to their extended lifespan and reduced maintenance requirements. Selecting the right bearing type depends on factors such as load capacity, speed, noise considerations, and long-term cost implications, ensuring optimal performance and reliability across various industrial and mechanical applications.

References

- 1.”The Difference Between Plain, Ball and Roller Bearings” from Sail-World;

- 2. “Roller BearingsVs Ball Bearings:Similarities, Differences & Applications” from SLS Bearings;

- 3. “Ball Bearings vs.Roller Bearings: What are the Key Differences?” from IBT Industrial Solutions.