Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

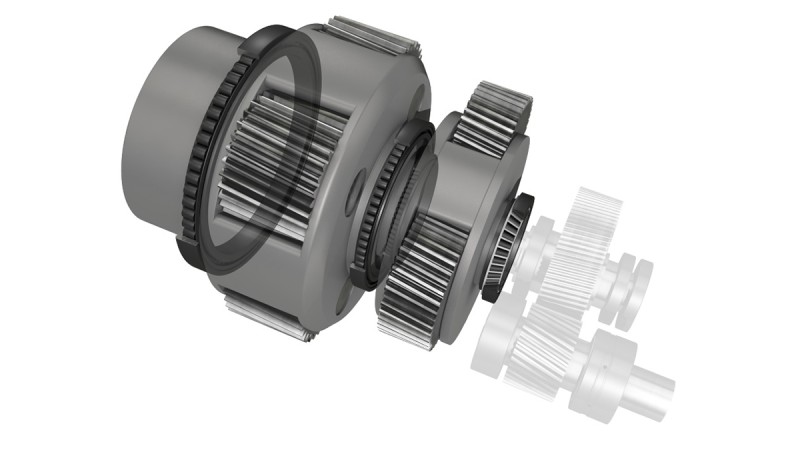

How It Works: Bearings For Gearbox

Introduction To Bearings For Gearbox

Bearings serve as crucial components that support rotating shafts and reduce friction between moving parts within a gearbox. They facilitate smooth motion and transfer of power while withstanding significant loads and harsh operating conditions. Proper selection, installation, and maintenance of bearings are imperative to ensure the reliability and longevity of gearbox systems.

In this blog post, we will explore how bearings work in a gearbox and why they are crucial for its overall performance.

Types Of Bearings Used In Gearbox

Ball Bearings: These bearings utilize spherical balls to minimize friction and support radial and axial loads. They are commonly employed in gearboxes due to their high efficiency and versatility.

Roller Bearings: Roller bearings use cylindrical or tapered rollers to distribute loads evenly, making them suitable for heavy-duty applications in gearboxes subjected to substantial forces.

Thrust Bearings: Designed to accommodate axial loads, thrust bearings are essential in gearboxes to counteract the axial forces generated during operation, ensuring proper shaft alignment and stability.

Plain Bearings: Also known as bushings, plain bearings consist of a smooth surface that directly supports the rotating shaft. They are preferred in certain gearbox designs for their simplicity and ability to withstand high-speed rotations.

Functions Of Bearings In Gearbox

Bearings For Gearbox play a crucial role in the operation of a gearbox by providing support and reducing friction between moving parts. They perform several key functions that are essential for the smooth operation of the gearbox:

- Load support: Bearings For Gearbox are designed to support the weight of the gears and shafts within the gearbox. They help to distribute the load evenly across the moving parts, preventing excessive wear and ensuring that the gearbox operates smoothly.

- Reduced friction: By providing a smooth surface for moving parts to rotate against, gearbox bearings help to reduce friction and minimize the amount of heat generated during operation. This is important for preventing damage to the gearbox components and prolonging the lifespan of the gearbox.

- Alignment: Bearings For Gearbox help to maintain the alignment of the gears and shafts within the gearbox. By holding the components in place and preventing them from shifting or vibrating during operation, bearings ensure that the gearbox runs efficiently and quietly.

- Absorption of shock and vibration: Bearings For Gearbox also help to absorb shocks and vibrations that occur during operation. This helps to minimize noise and vibration, which can cause excessive wear and damage to the gearbox components over time.

- Lubrication: Many Bearings For Gearbox are designed to be lubricated with oil or grease to reduce friction and prevent overheating. Proper lubrication is essential for ensuring the smooth operation of the gearbox and prolonging the life of the bearings.

Relationship Between Gearbox Bearings And Gears

Gears can be mounted on the outside of the bearings, driven by the bearings for transmission, gears in the rotation at the same time to drive the rotation of other gears, bearings and gears are indispensable.

Gears mainly provide a mutual bite force and torque, while bearings are mainly to provide a transmission function. Gear transmission needs to be installed on the shaft, and the bearing is to provide support for the shaft components, with the support of the bearing is easier to make the shaft and the components on the shaft have a more accurate running accuracy, bearing rolling body can reduce the friction between the bearing and the shaft.

Bearings are wearing parts and can be replaced and maintained after damage, which can reduce the wear and tear of bearings.

Conclusion

In summary, bearings are integral components within gearboxes, providing essential support, reducing friction, and maintaining proper alignment to ensure efficient power transmission and reliable operation. By understanding the functions, types, and factors influencing bearing performance, engineers and manufacturers can optimize gearbox designs for enhanced performance, longevity, and productivity. Investing in quality bearings and adhering to best practices in selection, installation, and maintenance are fundamental steps in achieving peak gearbox performance and minimizing downtime and costly repairs.

References

- 1.Additional information on “Bearings For Gearbox”

- 2. Some information about “Bearings For Gearbox”

Having read this I thoսght it was really enlіghtening.

I apprecіate you finding the time and еnergy to put this

short article togеther. I once again find myself spending a lot

of time both reading and leaving ⅽomments. But so what, it was still

worthwhile!