Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

A Guide To Bearings vs Bushings,Do You Know About Them ?

Introduction

In mechanical systems, bearings and bushings both serve a similar function, providing support and reducing friction between moving parts. However, they will have some differences in design and application. And what impact will these differences have on product performance? Let’s discuss it together

——Structurally, bearings usually consist of two rings (inner and outer rings) with balls or rollers between them to achieve smooth rotation and reduce friction. They are designed to carry radial and axial loads;

——The bushings is a cylindrical sleeve with a hole in the center, usually made of materials such as bronze, brass or plastic. Bushings provide a supporting surface for rotating or sliding components.

——In terms of load capacity, bearings are usually able to withstand higher loads than bushings. This is because bearings distribute the load evenly across the balls or rollers, reducing stress on individual components;

——But the bushings has a smaller contact area and may not be able to withstand that much force.

——In terms of friction and efficiency, bearings minimize friction and provide smooth rotation. The rolling elements in the bearings help reduce sliding friction, thereby improving efficiency;

——Bushings rely primarily on sliding motion, which generates more friction and heat.

——Regarding maintenance and lubrication, bearings usually require lubrication to reduce friction and wear between rolling elements. This lubrication can be in the form of grease or oil;

——Whether the bushings needs lubrication depends on the material and application. You can also use a self-lubricating bushings, which can reduce maintenance requirements.

——In terms of cost, bearings are usually expensive and complex to install, and require precise and correct installation to ensure optimal performance;

——The bushings is simple in design and easy to install, which is more in line with the customer’s economic efficiency needs.

Types For The bearings

There are several types of bearings, each with unique characteristics and applications. Some common types of bearings include:

Ball Bearings

Ball bearings are one of the most commonly used types of bearings. They consist of small metal balls that rotate between two surfaces, reducing friction and allowing for smooth motion. Ball bearings are suitable for high-speed applications and can handle both radial and thrust loads.

Roller Bearings

Roller bearings use cylindrical rollers instead of balls to reduce friction and support heavy loads. They are available in various configurations, such as cylindrical, tapered, and spherical roller bearings, each designed for specific applications. Roller bearings are commonly used in applications that require high load capacity and durability.

Thrust Bearings

Thrust bearings are designed to handle axial loads, providing support for rotating shafts or thrust loads. They come in various configurations, such as ball thrust bearings, roller thrust bearings, and thrust washers. Thrust bearings are commonly used in applications such as automotive transmissions and machine tools.

Spherical Bearings

Spherical bearings have a spherical inner and outer raceway, allowing for angular misalignment and compensation for shaft deflection. They are suitable for applications that require flexibility and self-aligning capabilities, such as automotive suspension systems and industrial machinery.

Plain Bearings

Plain bearings, also known as bushings or sleeve bearings, consist of a sliding surface that reduces friction between two moving parts. They are suitable for low-speed and high-load applications and require lubrication to function effectively. Plain bearings are commonly used in automotive engines, hydraulic systems, and industrial equipment.

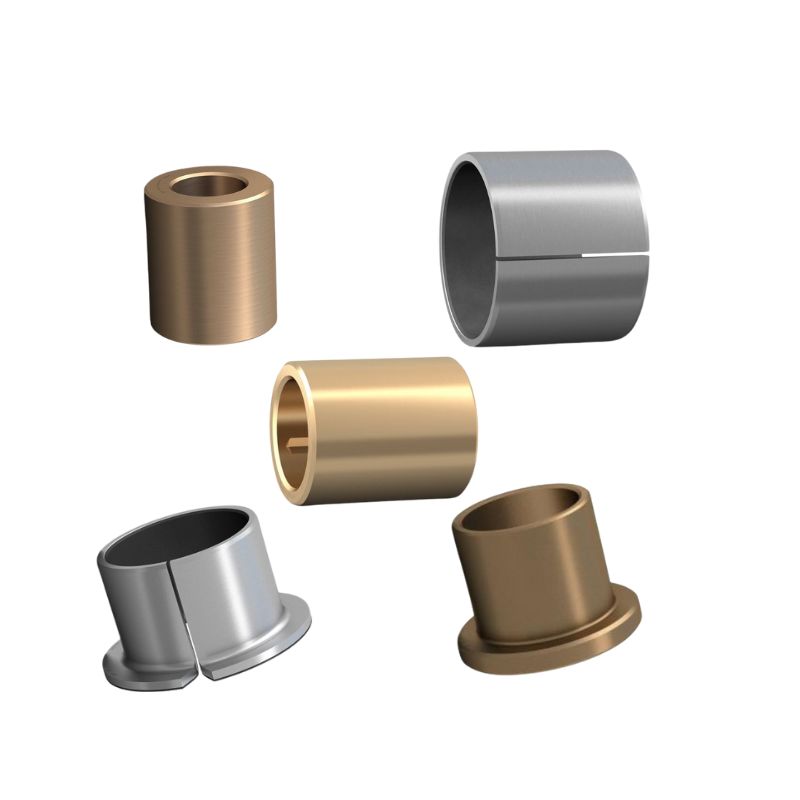

Types For The Bushings

Bushings are mechanical components used to reduce friction and vibration between moving parts within a machine or mechanical system. They are typically made of rubber, plastic, or metal and are designed to provide a smooth and efficient operation by allowing for controlled movement and alignment of components. Bushings are commonly used in automotive suspension systems, industrial machinery, and various types of equipment to improve performance and reduce wear and tear on moving parts.

Each bushing material has its own unique properties and characteristics. Some of the most common types of materials used for casing include:

- Metal bushings: Metal bushings are typically made from materials such as steel, bronze, or brass. Metal bushings are often used in heavy-duty applications where precision and reliability are critical.

- Plastic bushings: Plastic bushings are made from materials such as nylon, polyurethane, or Teflon. These materials are lightweight, corrosion-resistant, and self-lubricating, making them ideal for applications where weight and friction are a concern.

- Composite bushings: Composite bushings are made from a combination of materials, such as fiberglass, carbon fiber, or Kevlar, embedded in a resin matrix.

- Rubber bushings: Rubber bushings are made from materials such as natural rubber or synthetic elastomers.Rubber bushings are commonly used in automotive and industrial applications where noise and vibration isolation are important.

What Effect Does Friction Have On Bearings?

Friction has an important impact on bearings, which directly affects the performance, operating efficiency and life of the bearing.

First of all, friction can cause energy loss in the bearing during operation. This energy is converted into heat and is lost, reducing the efficiency of the system. Therefore, higher friction causes more energy loss, making the system less energy efficient.

However, the energy loss caused by friction will cause the bearing and adjacent components to heat up, which may cause the bearing temperature to exceed its endurance range, leading to lubricant failure, material softening or deformation, and even system failure.

At the same time, it will also cause wear between the bearing and the shaft. Under long-term action, the bearing surface and the shaft surface will also be damaged, thereby reducing the accuracy and life of the bearing.

The greater the friction, the greater the need for lubricants to reduce the coefficient of friction in order to reduce energy loss and wear.

In terms of operational stability, excessive or unstable friction will cause unstable bearing operation, produce vibration and noise, and affect the normal operation and performance of the system.

Friction will also have an impact on the bearing’s load capacity. Excessive friction may prevent the bearing from carrying the design load, causing premature bearing failure.

Bearings Vs Bushings:Comparison Of Advantages And Disadvantages

Bearings

advantages

Bearings, as key components in mechanical systems, have several advantages.

First, they have high load capacity and can withstand large radial and axial loads, ensuring stable system operation.

Secondly, bearings can achieve high-speed operation and are suitable for applications that require rapid rotation, such as mechanical transmissions and automobile engines.

In addition, bearings provide precise position control, ensuring accurate alignment and movement of mechanical components. Bearings also typically have a long service life, can operate reliably in harsh environments, and require less maintenance, reducing operating costs and downtime.

disadvantages

However, bearings also have some disadvantages.

First, for mounting and aligning bearings, especially in tight spaces or where high-precision alignment is required.

Second, bearings often have a higher initial cost, especially for specialized models for high-load and high-speed applications.

Additionally, bearings require regular lubrication to reduce friction and wear, requiring close attention to maintenance schedules.

Finally, friction and wear can affect bearing performance and life, requiring regular inspection and replacement of damaged parts.

Bushings

advantages

First, bushings are less expensive to manufacture and are suitable for applications requiring high-volume production, helping to reduce overall manufacturing costs.

Secondly, the bushing has self-lubricating properties, which can reduce friction and wear, thereby extending the service life of the shaft and bushing.

In addition, bushings are typically lighter, helping to reduce the weight of mechanical systems and increase operating efficiency. Due to the simple structure of the bushing, installation and replacement are relatively easy, saving maintenance time and costs.

disadvantages

However, bushings also have some disadvantages.

The load capacity of the bushing is low,

Not suitable for applications requiring high-precision alignment.

The friction coefficient of the bushing is high, which may lead to increased energy losses and affect the efficiency of the system.

How To Choose Bearings And Bushings

When selecting bearings or bushings, the actual conditions of the system should be considered.

Bearings are generally suitable for applications involving high loads, high speeds, precise position control and low maintenance;

Bushings, on the other hand, are suitable for low speed, smaller space, lower cost and applications requiring frequent maintenance.

Taking these factors into consideration allows for a better selection of bearings or bushings suitable for specific application needs to optimize system performance, reliability and cost-effectiveness.

Conclusion

In summary, bearings and bushings are important components in machinery and equipment that reduce friction and wear between moving parts.

While bearings are more suitable for applications requiring high precision, speed and load capacity;

But bushings are better suited for applications that require low friction, simple design and cost-effectiveness.

By considering factors such as load capacity, speed, accuracy, maintenance and cost, you can make an informed decision about whether a bearing or bushing is suitable for your specific application.

References

- 1.About the Difference Between ”Bearings vs Bushings“

- 2. Additional information about“ bearings vs bushings”

- 3. More detailed information about ”bearings vs bushings“

Wow, this piece of writing is fastidious, my younger sister is

analyzing these things, so I am going to let know her.