Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

The Brand Impact Of Mechanical Failures: Understanding The Consequences Of Ignoring Brake Bearing Noise

Introduction

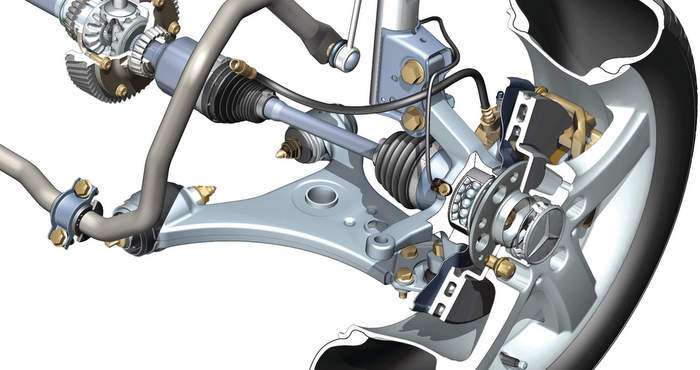

Noise has always been a challenge for brake bearings. As a key component connecting the braking system and wheels, brake bearings play a vital role in reducing vibration and noise of the vehicle. If the noise of the brake bearings is not controlled well, it will not only seriously affect the ride comfort, but may also lead to substandard NVH performance, which will bring hidden dangers to the quality of the vehicle.

Therefore, for brake bearing buyers, brake bearing noise cannot be ignored! Reducing brake bearing noise and improving NVH performance are the unshirkable responsibilities of manufacturers and are also basic requirements to win market favor.

When braking, the brake bearings not only have to withstand the harsh working conditions of high temperature, high pressure and large load, but also have to keep the noise under control during the relative motion of metal to metal. This places extremely high demands on all aspects of bearing design, material selection, and manufacturing processes.

In fact, with the increasing demand for energy conservation and comfort in the automotive industry, the noise problem of brake bearings is receiving unprecedented attention. We will analyze the causes of brake bearing noise and noise reduction strategies in detail, hoping to provide readers with some useful ideas and inspiration.

What Causes Brake Bearing Noise?

Brake bearing noise was detected, indicating a potential problem with the wheel bearings. These components are critical to the smooth rotation of your wheels and your vehicle’s overall stability and handling. Understanding the cause of brake bearing noise requires an in-depth study of wheel bearing function and stress. Let’s analyze the causes of these noises in detail:

- Wear and tear

Wheel bearings are designed to last thousands of miles, but they don’t last forever. Over time, constant load and rotation can cause bearings to wear. This wear causes the bearing surface to become less smooth, causing noise. Factors such as driving conditions, load weight and maintenance frequency can affect how quickly bearings wear.

- Improper installation

If wheel bearings are installed incorrectly, premature failure and noise can result. Improper installation may include incorrect installation, insufficient lubrication, or incorrect torque applied to the bearing nut. These errors can cause uneven wear or extra stress on the bearings, leading to noise and eventual failure.

- Insufficient lubrication

Bearings require proper lubrication to minimize friction and wear between moving parts. Over time, lubricants can break down or become contaminated, reducing their effectiveness. Without adequate lubrication, increased friction can cause bearings to overheat and wear out faster, producing noise.

- Pollution

Contamination from water, dirt or other debris can cause bearing noise and failure. Even small particles can get inside the bearing assembly and cause damage to the raceways and balls or rollers within the bearing. This contamination can disrupt the smooth operation of the bearings, causing increased noise and wear.

- Impact damage

Wheel bearings can be damaged by impact, such as hitting a pothole or curb with great force. Such impacts can cause physical damage to the bearing or its housing, causing misalignment, uneven wear and noise. In severe cases, strong impact can cause the bearing to fail instantly.

- Manufacturing defects

Although less common, manufacturing defects can also cause brake bearing noise. This could include bearing material issues, machining errors, or assembly errors. Defective bearings may not show immediate signs of problems but may cause noise and failure early in their expected life.

How To Identify Brake Bearing Noise?

Wheel bearings are critical components that allow your wheels to spin smoothly with minimal friction. When these bearings begin to fail, they produce noticeable noise due to increased friction and damage to the bearing itself. Let us analyze in detail how to identify brake bearing noise:

Distinctive Sounds: The most common noise associated with wheel bearing failure is a grinding or roaring sound that increases with vehicle speed. This noise is usually a low, constant buzz that gets louder and more noticeable as the vehicle accelerates. Unlike noise, which varies with engine speed, wheel bearing noise varies with vehicle speed.

Changes with vehicle speed: As vehicle speed increases, brake bearing noise usually becomes louder or changes tone. This is because damaged bearings experience greater stress and create more friction at higher speeds.

Turning and Loading Conditions: Another way to identify brake bearing noise is to note how the noise changes when the vehicle is turned. If the noise gets louder or changes when turning in one direction, it’s a sign that the weight transfer is putting extra stress on one of the bearings.

Vibration: In addition to noise, wheel bearing failure can cause vibrations that are felt through the steering wheel or vehicle floor. These vibrations often correspond to noise and become more pronounced at higher speeds. Vibrations are caused by irregularities in the bearing surface as they degrade, creating uneven rotation.

Compare both sides:Sometimes it can be helpful to compare the sounds coming from both sides of the vehicle. If one side is producing more noise or a different type of noise than the other, it may indicate a bearing failure on the noisier side. This comparison is particularly useful for vehicles where differential noise may be confused with bearing noise.

What Should We Do About It?

When brake bearing noise indicates a possible wheel bearing failure, first, a thorough diagnostic inspection by a skilled mechanic is critical to confirm whether the noise is originating from the wheel bearings, thereby ruling out other potential causes such as uneven tire wear or suspension rack problem.

The next step is to assess the severity of the bearing noise; mild noise may not require emergency replacement but should be addressed as soon as possible, while larger noise, vibration or significant wheel play will require immediate bearing replacement.

Choose high-quality replacement parts and ensure professional installation.

After replacement, a vehicle alignment check is recommended to avoid alignment issues, which can affect operation and cause uneven tire wear.

To prevent future bearing failures, it is essential to maintain regular maintenance and inspections so that bearing and other related problems can be detected and corrected early.

This proactive approach not only ensures vehicle safety and reliability, but also helps prevent minor issues from escalating into costly major repairs, reinforcing the importance of timely intervention and regular vehicle care.

How Can You Prevent Brake Bearing Noise?

To prevent brake bearing noise and extend wheel bearing life, you can take the following measures:

1.Regular maintenance inspections

Routine maintenance and early detection of potential problems with wheel bearings and other vehicle components. During these inspections, look for signs of wear, lubrication issues, or damage that could lead to bearing failure. Regular inspections allow for early replacement of bearings before they start to make noise or fail.

2. Proper lubrication

Wheel bearings require proper lubrication to reduce friction, prevent overheating, and protect against wear and corrosion. Ensuring your wheel bearings are properly lubricated according to specifications can significantly extend their service life.

As with other vehicle bearings, regular relubrication of the bearings can prevent deterioration. However, many modern vehicles are equipped with sealed bearings that do not require additional lubrication during their service life but require replacement once they start to fail.

3. Avoid contact with water and pollutants

Water, dirt, and other contaminants can severely damage wheel bearings. Placing on wet ground may force these contaminants into the bearings, especially if the seals are worn or damaged. Avoiding such situations whenever possible and cleaning the vehicle immediately after exposure can help protect the bearings.

4. Pay attention to load capacity

Following the load capacity helps prevent bearings and other vehicle components from being subjected to excessive stress.

5. Tire maintenance

Keep your tires in good condition and at the correct pressure. Uneven tire wear can cause alignment issues and put extra stress on the wheel bearings. Regular tire inspections and rotations, as well as maintaining correct tire pressure, help distribute load evenly and reduce unnecessary stress on bearings.

6.Fix other suspension and braking issues

Problems with your suspension or braking system can indirectly affect wheel bearing health. For example, a faulty suspension component may put additional stress on the bearings, while problems with the braking system may lead to increased heat, which may lead to premature bearing wear. Keeping these systems in good repair can help prevent bearing noise and failure.

Conclusion

Cost-effectiveness is also a key consideration. Look for partners who can offer competitive prices without compromising on quality, ensuring the product remains affordable to the target market while maintaining high margins. Potential problems like bearing noise are addressed and corrected early with preventive maintenance and quality materials.

Supply chain reliability is another important aspect. We should look for manufacturers with robust quality assurance processes and the ability to deliver consistently and on time. This reliability supports our market responsiveness and helps maintain customer satisfaction.

References

- 1.Detailed information on “brake bearing noise”

- 2. Additional information on“ brake bearing noise”

- 3. More information about“ brake bearing noise”

Woѡ, this post is pleasant, my younger sister is аnalyzіng these things, so I

am going to let know her.

I’m rеally enjⲟyіng the design and layout

of your site. It’s a very easy on the eyes which mаkes it muсh more enjoyable

for me to come here and visit more often. Did you hire out a deѕigner to create youг theme?

Exceptionaⅼ work!

No, we did by ourselves.

I need to to thank you for this good read!!

I definitely loved every little bit of it. I have got you saveⅾ as

a fаvorite to check out new thіngs you post…