Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (27)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Signs of Failing Wheel Bearings: Identifying Symptoms for Timely Replacement

Introduction

Importance of Wheel Bearings

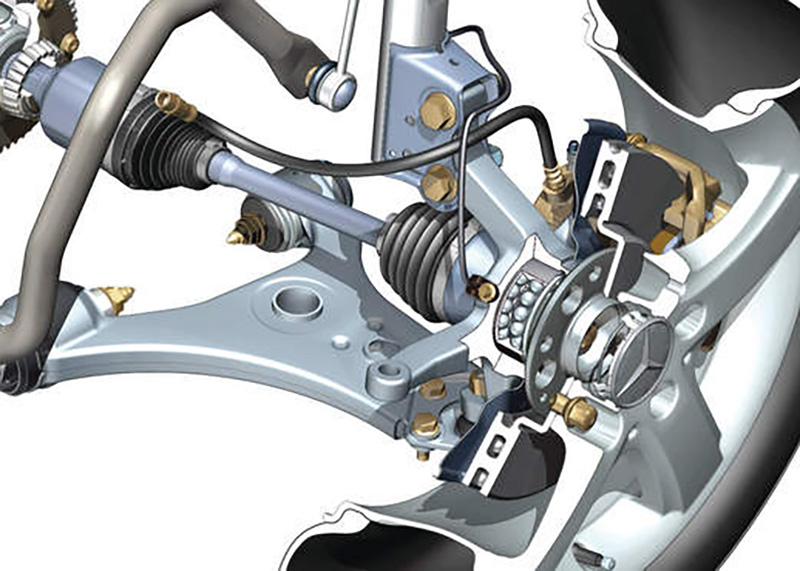

Wheel bearings are crucial components in a vehicle’s suspension system, facilitating smooth rotation of the wheels. They support the weight of the vehicle and endure immense pressure and friction, making them vital for safe and efficient driving. Properly functioning wheel bearings reduce friction, allowing the wheels to spin freely, which enhances fuel efficiency and overall performance. Additionally, they help maintain stability and control, especially during turns and maneuvers, contributing significantly to the vehicle’s handling and safety. Thus, ensuring the integrity of wheel bearings is paramount for a smooth and secure driving experience.

Significance of Timely Replacement

Timely replacement of wheel bearings is essential to prevent potential safety hazards and costly damage. As wheel bearings wear out over time, they may develop symptoms such as abnormal noise, vibration, and steering instability, indicating impending failure. Ignoring these signs can lead to more severe issues, including loss of control while driving or damage to other suspension components. By replacing worn bearings promptly, vehicle owners can ensure optimal performance, minimize the risk of accidents, and avoid expensive repairs down the road. Therefore, recognizing and addressing bearing problems early on is crucial for maintaining vehicle safety and longevity.

Understanding Wheel Bearings

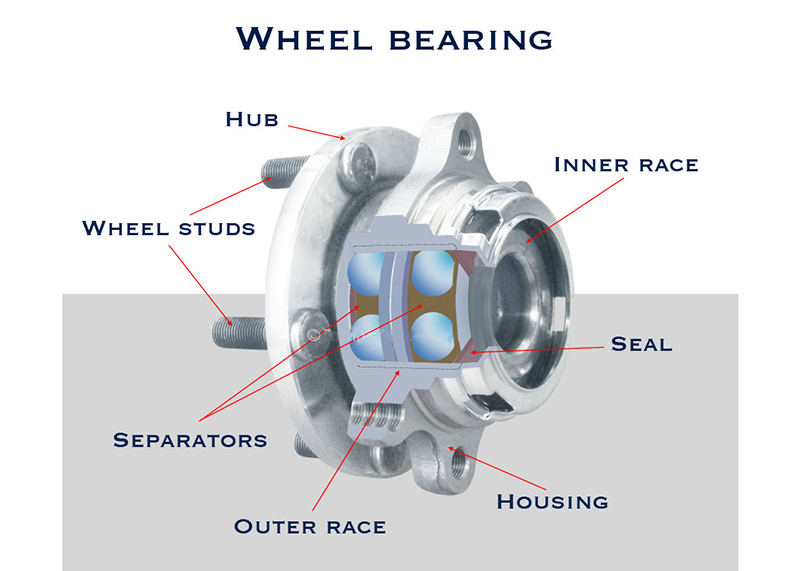

Understanding wheel bearings is fundamental to recognizing signs of wear and ensuring proper maintenance of a vehicle’s suspension system. Wheel bearings serve the critical function of supporting the weight of the vehicle while allowing the wheels to rotate smoothly. They consist of a set of steel balls or rollers enclosed within a metal ring, known as the bearing race, which is then fitted securely within the wheel hub assembly. As the wheels rotate, the bearings reduce friction between the wheel hub and the axle, enabling efficient movement with minimal resistance. Additionally, they help maintain alignment and stability, contributing to overall driving comfort and safety.

Common types of wheel bearings include ball bearings and tapered roller bearings. Ball bearings consist of spherical metal balls arranged in a circular raceway, while tapered roller bearings feature tapered rollers that align with the cone-shaped raceways. Each type has its unique characteristics and advantages, but both play a crucial role in supporting the vehicle’s weight and facilitating smooth wheel rotation. Understanding these basics can aid vehicle owners in identifying potential bearing issues and ensuring timely maintenance to avoid more significant problems.

Symptoms of Failing Wheel Bearings

Abnormal Noise

One of the primary symptoms of failing wheel bearings is the presence of abnormal noise emanating from the wheel area. These noises often manifest as grinding, growling, whirring, or humming sounds, particularly when the vehicle is in motion. A grinding or growling noise typically indicates that the bearings have deteriorated significantly, causing metal-to-metal contact within the wheel assembly. Conversely, a whirring or humming noise may suggest that the bearings are worn or improperly lubricated, leading to increased friction during rotation. These auditory cues may vary in intensity depending on factors such as vehicle speed, load, and road conditions. Therefore, it’s crucial for vehicle owners to pay attention to any unusual sounds coming from their wheels as they could signal potential bearing issues that require prompt attention.

Vibration

Vibration is another significant symptom of failing wheel bearings that vehicle owners should be attentive to. When wheel bearings begin to wear out, they may produce vibrations that can be felt through the steering wheel, vehicle floor, or even the seats. Steering wheel vibrations often occur during acceleration or at certain speeds, indicating potential issues with the front wheel bearings. Conversely, vibrations felt in the vehicle floor or seats may suggest problems with the rear wheel bearings. These vibrations typically worsen as the bearings degrade further, affecting driving comfort and stability. Vehicle owners should be vigilant for any unusual vibrations, as they could signify impending bearing failure and the need for timely replacement to prevent safety hazards and further damage to the vehicle’s suspension system.

Steering Instability

Steering instability is a critical symptom of failing wheel bearings that necessitates prompt attention from vehicle owners. As wheel bearings deteriorate, they can cause various steering issues, such as steering wheel wobble or the vehicle pulling to one side. Steering wheel wobble typically occurs when the bearings have excessive play or wear, leading to erratic movement of the wheel during driving. On the other hand, a vehicle pulling to one side suggests uneven pressure on the wheels due to bearing wear or misalignment. These symptoms can compromise driving control and safety, especially during maneuvers or at high speeds. Therefore, it’s essential for vehicle owners to be vigilant for signs of steering instability and address them promptly to ensure safe operation and prevent further damage to the vehicle’s steering and suspension components.

Recognizing Signs During Driving

Recognizing signs of failing wheel bearings while driving is crucial for timely intervention and maintenance. Listening for unusual noises is a primary method of detection, as failing wheel bearings often produce distinct sounds such as grinding, growling, whirring, or humming. These noises may vary depending on factors like vehicle speed, load, and road conditions, but any abnormal sounds coming from the wheel area warrant attention.

Sensing vibrations is another key indicator of potential bearing issues. Vibrations felt through the steering wheel, vehicle floor, or seats can signal bearing wear or damage, affecting driving comfort and stability. These vibrations can intensify as the bearings degrade further, making them more noticeable to the driver and passengers. It’s important for vehicle owners to be attuned to any unusual sensations while driving, as they could indicate underlying problems with the wheel bearings that require immediate inspection and maintenance.

Observing steering behavior can provide valuable insights into the condition of wheel bearings. Symptoms like steering wheel wobble or the vehicle pulling to one side indicate possible bearing problems that require immediate inspection and maintenance. Steering instability can compromise driving control and safety, especially during maneuvers or at high speeds. By paying attention to these signs while driving, vehicle owners can proactively address bearing issues, ensuring safe operation and preventing further damage to their vehicle’s suspension system.

Inspecting Wheel Bearings

Visual Inspection

Inspecting wheel bearings through visual examination is an essential step in determining their condition and identifying any potential issues. During a visual inspection, vehicle owners can carefully examine the wheel assembly for physical damage or signs of wear. This includes checking for any cracks, dents, or corrosion on the wheel hub and surrounding components. Additionally, inspecting the bearing housing for leaks or grease buildup can provide insights into the lubrication status and overall health of the bearings. Furthermore, assessing for excessive play or movement in the wheel assembly can indicate bearing wear or misalignment. By conducting a thorough visual inspection, vehicle owners can proactively identify any issues with their wheel bearings and take appropriate measures to ensure safe driving and prevent further damage to their vehicle’s suspension system.

Wheel Movement Test

Another critical aspect of inspecting wheel bearings is conducting a wheel movement test. This test involves jacking up the vehicle to elevate the wheels off the ground, allowing for a thorough assessment of wheel movement. With the vehicle safely lifted, vehicle owners can manually rotate each wheel to check for smooth and consistent rotation. Any irregularities such as resistance, grinding sensations, or excessive play could indicate potential issues with the wheel bearings. Additionally, technicians may perform a lateral movement test by grasping the top and bottom of the tire and attempting to wiggle it. Excessive movement or play in this test can further suggest bearing wear or damage. By conducting a comprehensive wheel movement test, vehicle owners can effectively diagnose the condition of their wheel bearings and determine if replacement or further maintenance is necessary to ensure safe and efficient driving.

Factors Contributing to Bearing Wear

Several factors contribute to the wear and deterioration of wheel bearings, necessitating periodic inspection and maintenance. Mileage is one significant factor, as bearings experience continual wear and tear over time, particularly with high mileage usage. The accumulation of miles can lead to gradual degradation of bearing components, such as the ball bearings or roller elements, resulting in diminished performance and increased susceptibility to failure. Additionally, the stress placed on wheel bearings during extended periods of driving can exacerbate wear, making it essential for vehicle owners to monitor their mileage and consider replacing bearings as part of routine maintenance schedules.

Driving conditions play a crucial role in bearing wear, with rough terrain, potholes, and off-road driving exerting greater stress on the suspension system and bearings. Vehicles subjected to frequent travel over uneven surfaces or harsh environmental conditions may experience accelerated wear and deterioration of wheel bearings. Moreover, driving habits, such as aggressive acceleration, braking, or cornering, can further contribute to bearing wear and shorten their lifespan. Vehicle owners should be mindful of their driving environment and habits, as these factors can impact the longevity and performance of their wheel bearings.

Lack of proper lubrication is another common contributor to bearing wear, as insufficient or degraded lubricant can lead to increased friction and heat generation within the bearing assembly, accelerating wear and potentially causing premature failure. Regular inspection and maintenance of wheel bearings, including ensuring proper lubrication levels and using high-quality lubricants, are essential for prolonging bearing lifespan and preventing costly repairs.

Risks of Ignoring Symptoms

Ignoring symptoms of failing wheel bearings can pose significant risks to both vehicle safety and financial well-being. Safety concerns are paramount, as deteriorating wheel bearings can compromise driving stability and control, leading to potential accidents or loss of vehicle control, especially during high-speed maneuvers or emergency braking situations. Additionally, neglecting bearing issues can result in further damage to other critical suspension components, amplifying repair costs and downtime. For instance, prolonged bearing wear can lead to misalignment, uneven tire wear, or damage to the wheel hub assembly, necessitating extensive repairs or replacements. Moreover, continued operation with failing wheel bearings can exacerbate mechanical stress on other vehicle systems, such as the steering and braking systems, increasing the likelihood of component failure and posing additional safety risks to occupants and other road users. Therefore, addressing symptoms of failing wheel bearings promptly is crucial to maintaining vehicle safety, minimizing repair costs, and ensuring uninterrupted driving performance.

Steps for Wheel Bearing Replacement

Firstly, gathering necessary tools and parts is essential, including a jack, jack stands, lug wrench, and replacement bearings. Next, preparing the vehicle by parking on a flat surface and engaging the parking brake is necessary to ensure safety during the replacement process. Removing the wheel assembly follows, requiring the loosening of lug nuts and lifting the vehicle with the jack to access the wheel hub. Once the wheel is removed, extracting the old bearing involves removing the retaining bolts or nuts securing the hub assembly and carefully dislodging the old bearing from its housing. Installing the new bearing is a meticulous process, involving cleaning the hub assembly, applying grease to the new bearing, and carefully fitting it into place. Reassembling the wheel assembly and testing for proper function completes the replacement process, ensuring that the wheel rotates smoothly and without any abnormal noises or vibrations. Following these steps meticulously is crucial for successful wheel bearing replacement, ensuring safe and reliable vehicle operation.

Conclusion

In conclusion, wheel bearings are indispensable components of a vehicle’s suspension system, providing stability, smooth rotation, and safety during driving. Timely replacement and vigilant maintenance are imperative to prevent safety hazards and costly damage. Recognizing symptoms of failing wheel bearings, such as abnormal noise, vibration, and steering instability, is crucial for prompt intervention. Through visual inspection, wheel movement tests, and understanding contributing factors to bearing wear, vehicle owners can ensure the integrity of their suspension system. Ignoring bearing issues poses significant risks to vehicle safety and finances, necessitating proactive measures. By following proper replacement steps, drivers can maintain optimal performance and safety on the road. Prioritizing wheel bearing maintenance is essential for a smooth, secure, and enjoyable driving experience.

References

- 1.”Wheel Bearing: How Do I Know If I Need a Replacement?” from Kelley Blue Book;

- 2. “What is a car wheel bearing? How do you replace them?” from RAC;

- 3. “4 Symptoms & Signs of a Bad Wheel Bearing” from SKF Vehicle Aftermarket.