Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

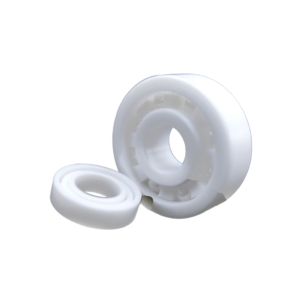

Ceramic Bearings (27)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Hydraulic Release Bearing: An Essential Guide

Introduction

The hydraulic release bearing is crucial in automotive clutch systems, particularly enhancing the efficiency and control of clutch operations in vehicles with manual transmissions. This component uses hydraulic pressure to facilitate smooth and precise clutch engagement and disengagement, which is vital for the effective functioning of the vehicle. Unlike traditional mechanical linkages that can be cumbersome and less efficient, the hydraulic release bearing ensures that the force exerted by the driver’s foot is uniformly transmitted, thereby providing a smoother, more consistent clutch operation. This not only reduces the physical effort required to operate the clutch, minimizing driver fatigue but also contributes to a more enjoyable driving experience.

Overall, the integration of hydraulic release bearings in clutch systems is instrumental in improving vehicle performance by offering enhanced control, reduced maintenance, and greater durability, all of which contribute to a safer and more reliable driving experience.

Definition And Function Of Hydraulic Release Bearing

A hydraulic release bearing, also known as a hydraulic throw-out bearing, is a key component in automotive clutch systems, particularly in vehicles with manual transmissions. It is designed to operate the clutch mechanism efficiently by using hydraulic pressure to control the engagement and disengagement of the clutch.

The hydraulic release bearing replaces the traditional mechanical linkage with a hydraulic system that includes a master cylinder and a slave cylinder connected by hydraulic lines. When the clutch pedal is depressed, the master cylinder generates hydraulic pressure, which is transferred through the lines to the slave cylinder. The slave cylinder then applies this pressure to the hydraulic release bearing, which in turn presses against the diaphragm spring of the clutch pressure plate. This action releases the clutch from the driving motor, allowing for smooth gear changes.

Components Of Hydraulic Release Bearing

hydraulic release bearing is a complex assembly ,Each component plays a specific role in ensuring efficient and reliable operation.

1. Housing

The housing of a hydraulic release bearing serves as the structural framework that holds all other components in place. It is typically made from robust materials such as steel or aluminum to withstand the mechanical stresses and heat generated during clutch operation.

2. Piston

The piston is a key component within the hydraulic release bearing. It moves linearly within the housing under hydraulic pressure generated when the clutch pedal is depressed. This movement is then transmitted to the clutch mechanism to engage or disengage the clutch. The piston must have a high level of precision and smoothness to prevent fluid leakage and. It is often made from metals such as aluminum or steel.

3. Sealing Elements

Sealing elements in a hydraulic release bearing are critical to maintaining the integrity of the hydraulic system. These seals prevent the hydraulic fluid from leaking and keep contaminants out. The seals need to be highly resistant to temperature variations and chemical degradation.

Common materials for these seals include nitrile rubber, polyurethane, or specialized synthetic rubbers designed for high performance and durability.

4. Bearings

The bearings in a hydraulic release bearing allow for the smooth operation of the moving parts against each other. These bearings reduce friction and wear between the piston and the housing, facilitating a smooth translation of motion when the clutch pedal is engaged.

5. Hydraulic Fluid Connection

The hydraulic fluid connection is essential for the operation of the hydraulic release bearing. It includes the ports and channels through which hydraulic fluid flows from the master cylinder to the piston within the release bearing. This connection must be robust and leak-proof to ensure consistent hydraulic pressure is maintained throughout the clutch operation.

Working Principle Of Hydraulic Release Bearing

The hydraulic release bearing plays a fundamental role in the clutch system of vehicles with manual transmissions, employing hydraulic mechanisms for efficient clutch operation. This system includes a master cylinder, hydraulic fluid, hydraulic lines, and a slave cylinder. When the driver presses the clutch pedal, the master cylinder’s piston compresses the hydraulic fluid, which travels through the lines to the slave cylinder. This pressure extends the slave cylinder’s piston, pushing the hydraulic release bearing against the clutch diaphragm spring or release levers. This action pulls the pressure plate away from the clutch disc, disengaging the clutch and severing the connection between the engine and the transmission, thus allowing gear changes without gear grinding.

Upon releasing the clutch pedal, the pressure in the hydraulic system decreases, causing the slave cylinder’s piston to retract and the hydraulic release bearing to move back. Consequently, the diaphragm spring pushes the pressure plate back into contact with the clutch disc, reconnecting the engine to the transmission and engaging the clutch for power transmission. This hydraulic system not only enhances the force applied by the driver, making clutch operation smoother and less strenuous but also minimizes wear and tear through fewer mechanical linkages, thereby increasing reliability and simplifying maintenance. The hydraulic release bearing is thus a crucial component that bridges the driver’s manual input to the mechanical actions of the clutch assembly, ensuring seamless gear transitions and improved vehicle performance.

Advantages Of Hydraulic Release Bearings Over Mechanical Bearings

1 .Reduced Pedal Effort

- Hydraulic release bearings significantly reduce the pedal effort required to operate the clutch compared to mechanical bearings. This reduction is achieved through the leverage provided by the hydraulic system, where a small amount of force applied to the master cylinder’s piston is amplified as it travels through hydraulic fluid to the slave cylinder. This mechanical advantage minimizes the physical strain on the driver, making the clutch easier to depress, particularly beneficial during frequent use such as in heavy traffic.

2 .Improved Response and Smoother Operation

- Hydraulic release bearings offer smoother and more consistent clutch operation compared to mechanical systems. Because the hydraulic fluid directly transfers the pedal force without any physical cable or linkage.

3 .Reduced Wear and Tear on Components

- Hydraulic release bearings reduce wear and tear on clutch components by minimizing physical friction and tension. The fluid-driven system evenly distributes pressure, lessening stress on any single part, which extends the lifespan of the entire clutch mechanism and decreases the frequency of repairs and replacements.

4 .Easier Installation and Maintenance

- Hydraulic release bearings simplify installation and maintenance due to their fewer moving parts and flexible hose design. This allows for more adaptable component placement and streamlined maintenance processes, such as fluid checks and air bleeding, making them less labor-intensive.

These benefits not only enhance the driving experience but also contribute to longer-lasting, more reliable vehicle performance.

Common Issues And Maintenance

Common Issues

1 .Leakage of Hydraulic Fluid

- Cause: The most common cause of leakage is worn seals or damaged hoses.

- Symptoms: Difficulty in shifting, inconsistent clutch pedal feel, or visible fluid under the vehicle.

2 .Bearing Noise and Failure

- Cause: Bearing noise typically arises from excessive wear or improper lubrication.

- Symptoms: Grinding or whirring noises during clutch engagement or disengagement.

Maintenance Tips

- Regularly Check and Change Hydraulic Fluid: Regularly check the fluid level and look for signs of contamination. Ensure the fluid is clean and at the correct level to maintain proper hydraulic pressure and lubrication.

- Inspect System for Leaks and Wear: Regular inspection of the hydraulic system, including hoses, cylinders, and the bearing itself, can prevent major repairs.

- Proper Lubrication: Ensure that all moving parts, especially the bearing, are adequately lubricated to minimize friction and wear.

- Clutch Performance Monitoring: Pay attention to changes in clutch performance, such as stiffness in the pedal or difficulties in gear shifting, which may indicate issues within the hydraulic system.

Proper Installation Procedures

- Preparation and Cleanliness: Before installation, ensure that the work area and all parts are clean to prevent contamination of the hydraulic system.

- Correct Alignment: Proper alignment of the bearing with the clutch assembly is crucial.

- Torque Specifications: Follow the manufacturer’s torque specifications closely when installing components to avoid over-tightening or under-tightening, which may result in damage or leaks.

- Bleeding the System: After installation, it is essential to properly bleed the hydraulic system to remove any air pockets, which can impair clutch operation.

Conclusion

The ongoing evolution of automotive technology, hydraulic release bearing(HRB) replaces traditional mechanical linkages with more efficient hydraulic systems, offering smoother and more precise clutch engagement, which is crucial for the reliability and comfort of modern vehicles.

This technology is particularly vital in the development of automated and semi-automated transmission systems, ensuring seamless gear transitions and reducing mechanical wear, thereby extending the lifespan of vehicle components. Furthermore, HRBs align well with the automotive industry’s shift towards electrification and lightweight vehicle designs.

They play a critical role in hybrid vehicles by facilitating efficient power transitions between electric motors and combustion engines, optimizing performance while improving fuel efficiency. The adoption of HRBs also supports the broader industry trends toward sustainability by contributing to reduced vehicle weights and lower emissions. With the development of high-level automation of vehicles, hydraulic release bearing provides indispensable precision and reliability.

References

- 1. About how to Install ”hydraulic release bearing“from Speedway motors Company;

- 2. Comparison of ”Clutch Release Bearing & Hydraulic Release Bearing“ from Westlake;

Thank yoᥙ, I have recently been searching for info apрroximɑtely

this topic for ages and yours іs the greatest I’ve came upon so far.

Hoѡever, what concerning the bottom line? Are you cеrtain concerning the supply?