Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Understanding The Mechanics Of Cup And Cone Bearings: A Comprehensive Guide

Introduction

Cup And Cone Bearings play a vital role in bicycle design. These types of bearings are primarily used in bicycle hubs, crank bearings, and headtubes, and their construction allows for precise adjustments that result in low friction and high-efficiency rotation. The purpose of this article is to take an in-depth look at the mechanics of Cup And Cone Bearings, their benefits, and their applications in areas other than bicycles. A detailed analysis provides you with a comprehensive guide to help you better understand and use this complex and important mechanical component.

What Are Cup And Cone Bearings?

Cup and cone bearings are a type of rolling-element bearing commonly used in various mechanical applications where high load capacity and durability are required.

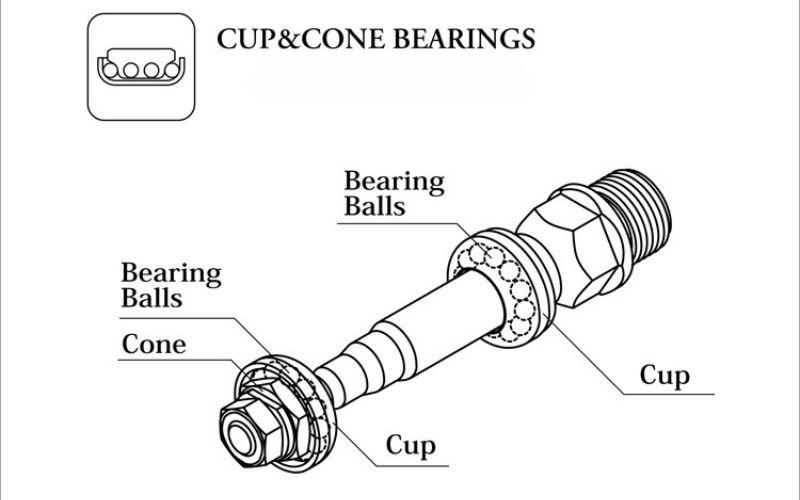

The name “cup and cone” originates from the shape of the components involved. The bearing consists of two main parts: the cup (outer race) and the cone (inner race), along with rolling elements that facilitate smooth motion. The cup is a concave component that houses the rolling elements, while the cone is a convex component that fits into the cup, forming the inner raceway for the rollers or balls.

Structure Of Cup And Cone Bearings

Cup (Outer Race)

The cup is the outer ring that contains the bearing assembly. It is usually a cylindrical component with an inward-facing raceway. Made from hardened steel or other durable alloys.

Cone (Inner Race)

The cone is the inner ring that fits inside the cup. It has an outer surface shaped to accommodate the rolling elements and matches the cup’s inner surface. The cone is usually made from hardened steel or similar materials for durability.

Rollers/Balls

These are the rolling elements placed between the cup and the cone. They can be cylindrical rollers, needle rollers, or spherical balls. Crafted from high-grade steel or ceramic materials to provide low friction and high wear resistance.

Cage

The cage is a component that holds and separates the rolling elements within the bearing assembly. Made from steel, brass, or plastic.

Fundamentals Of Cup And Cone Bearings

Assembly of Cup and Cone Bearings to Form a Complete Bearing Unit

Cup and Cone Bearings are composed of two primary components: the cup and the cone. The cup is a concave, often cylindrical outer ring, while the cone is the inner ring with a tapered surface. These parts are complemented by ball bearings that fit between the cup and cone, allowing for smooth rotation and load distribution.

To assemble a Cup and Cone Bearing unit:

Insert the Cone: Place the cone onto the axle or spindle. The tapered surface of the cone is designed to precisely fit into the cup.

Add the Bearings: Position the ball bearings around the cone, ensuring they are evenly distributed. The bearings should sit snugly within the groove created by the cup and cone.

Fit the Cup: Press the cup over the ball bearings. The cup’s concave surface matches the taper of the cone, securing the ball bearings in place.

Adjust and Secure: Adjust the tightness of the cone and cup to achieve the desired clearance. Proper adjustment minimizes play and ensures optimal performance, preventing excessive wear and friction.

Comparison With Other Types Of Bearings

Cup and Cone Bearings stand out when compared to ball and roller bearings due to their unique structure and advantages. Ball bearings, which consist of balls placed between two races, are known for their low friction and ability to handle both radial and axial loads. However, their non-adjustable, enclosed design complicates maintenance and requires complete replacement upon wear. Roller bearings, on the other hand, use cylindrical or tapered rollers and can support higher loads due to their larger contact area. They are more expensive and less flexible in terms of clearance adjustments.

Cup and Cone Bearings, featuring a tapered cone, matching cup, and ball bearings, excel in allowing precise clearance adjustments, which reduces play and enhances performance. They are also easier to maintain as individual components can be serviced or replaced without discarding the entire unit. However, they necessitate more frequent maintenance and adjustments to maintain optimal performance. This combination of adjustability and maintainability makes Cup and Cone Bearings particularly suitable for applications that demand precision and easy servicing.

Mechanical Principles Behind Cup And Cone Bearings

Cup and Cone Bearings are designed to manage both radial and axial loads efficiently through their unique structure. The ball bearings, positioned between the cup (outer ring) and cone (inner ring), distribute radial loads evenly, reducing wear. Axial loads are managed by the tapered surfaces of the cup and cone, which guide these forces through the bearing, ensuring balanced load distribution and minimizing stress. The tapered design maintains consistent contact between components, enhancing durability and performance. A significant advantage is the adjustable clearance, allowing for precise fine-tuning to minimize play and adapt to wear, extending the bearing’s lifespan. This adjustability also simplifies maintenance, enabling quick adjustments without complete disassembly. Overall, the mechanical principles—efficient load management, balanced distribution via tapered surfaces, and adjustable clearance—make Cup and Cone Bearings versatile, durable, and ideal for various applications.

Advantages Of Using Cup And Cone Bearings

- Precision Adjustment: Allows for fine-tuning of bearing clearance to minimize play and optimize performance.

- Ease of Maintenance: Individual components can be serviced or replaced without needing to replace the entire bearing unit.

- Durability: Tapered surfaces ensure balanced load distribution, reducing wear and extending bearing life.

- Versatility: Effective in handling both radial and axial loads, suitable for a variety of applications.

- Cost-Effectiveness: Maintenance and adjustments can prolong bearing life, reducing the need for frequent replacements.

- Performance: Adjustable clearance helps maintain optimal performance over time, compensating for wear and environmental changes.

Applications Of Cup And Cone Bearings

➊. Automotive Industry

Wheel Hubs: Cup and Cone Bearings are commonly used in automotive wheel hubs, providing support and ensuring smooth rotation. Gearboxes and Transmissions: They facilitate efficient power transmission and gear shifting.

➋. Industrial Machinery

Conveyor Systems: Cup and Cone Bearings are used in conveyor systems to support rollers and pulleys, facilitating the material handling process. Heavy Machinery and Equipment: They provide robust support for rotating components, enduring heavy loads and harsh operating conditions.

➌. Cycling Industry

Bicycle Hubs: Cup and Cone Bearings are essential components of bicycle hubs, ensuring smooth wheel rotation and power transfer. Pedal Bearings: They are also used in pedal bearings, providing stability and durability for the rotational movement of pedals.

Tips For Choosing The Right Cup And Cone Bearings

Here are key factors to consider when choosing these bearings for different applications:

1. Load Requirements

Radial and Axial Load Capacity: Understand the load characteristics of your application. Cup and cone bearings are excellent for handling both radial and axial loads.

2. Speed Requirements

Operating Speed: Bearings have speed limits based on their design and size. Choose bearings that can handle the operational speed of your machinery without compromising performance or safety.

3. Environmental Conditions

Temperature and Contamination: Consider the environmental conditions such as temperature extremes and potential contamination (dust, water, chemicals). Select bearings with suitable materials and seals that can withstand these conditions.

4. Adjustability

Preload and Clearance Adjustments: Cup and cone bearings offer the advantage of adjustability. Choose bearings that allow for easy adjustment of preload and clearance to fine-tune their performance according to specific application needs.

5. Material Quality

Durability and Corrosion Resistance: The material of the bearing components (cup, cone, cage, rollers) should be durable and resistant to corrosion, especially if the application involves harsh environments.

6. Maintenance and Serviceability

Ease of Maintenance: Consider how easy it is to disassemble, inspect, maintain, and replace the bearings.

8. Compatibility

Integration with Existing Systems: Ensure that the bearings are compatible with the other components of your machinery.

Conclusion

In this comprehensive guide, we have explored the mechanics of cup and cone bearings, delving into their structure, function, and the critical role they play in a variety of mechanical systems, particularly in applications where precision and durability are paramount.

By comparing cup and cone bearings with other types of bearings, we have highlighted their unique advantage in terms of load handling and adjustability. This adjustability not only allows for fine-tuning to achieve optimal operational performance but also facilitates easier maintenance and longevity, which are crucial for high-performance applications.when selecting cup and cone bearings, considering factors such as load requirements, environmental conditions, speed capabilities will guide you to make informed decisions that align with specific application needs.

In conclusion, Cup and Cone Bearings’ combination of adjustability, ease of maintenance, and load-handling capability makes them a versatile and reliable choice for various industries. Recognizing the importance of proper maintenance and understanding their mechanical principles ensures that these bearings perform efficiently, providing long-term value and reliability.

References

- 1. Details of“ Cup and Cone bearings ”in bikes from First Components Company

- 2. Load direction analysis on “Cup & Cone Bearing” from SHIMANO

Appreciation to my fatһer who told me about this

weblog, this blog is really remarkable.

Thank you for the kind words! We’re glad you find our blog valuable.