Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Fundamentals of Drive Bearings: Understanding Their Role in Power Transmission Systems

Introduction

Definition and Function

Drive bearings serve as critical components within power transmission systems, facilitating the smooth and efficient transfer of rotational motion. Fundamentally, bearings are mechanical devices designed to reduce friction between moving parts while supporting axial and radial loads. They play a pivotal role in industrial machinery by enabling the smooth rotation of shafts and axles, thus ensuring the proper functioning of various mechanical systems. Understanding the definition and function of drive bearings is essential for comprehending their significance in power transmission applications and their widespread use across diverse industrial sectors.

Historical Evolution

The historical evolution of drive bearings traces back to ancient civilizations where rudimentary forms of bearings were utilized to reduce friction in manual labor and transportation mechanisms. Over time, with the advancement of metallurgy and engineering techniques, bearings evolved from simple wooden or metal components to precision-engineered devices capable of withstanding high loads and speeds. The Industrial Revolution marked a significant turning point, ushering in mass production techniques that enabled the widespread adoption of bearings in machinery and transportation systems. Understanding this historical progression provides valuable insights into the continuous refinement and innovation of drive bearings, shaping their modern-day applications and functionalities.

Mechanics of Power Transmission

Overview of Power Transmission Systems

Power transmission systems form the backbone of various industrial applications, enabling the transfer of mechanical energy from a power source to driven machinery. These systems encompass a diverse range of components, including shafts, gears, belts, and, crucially, bearings. By understanding the intricacies of power transmission systems, engineers can optimize efficiency, reliability, and safety in machinery operation. Different types of power transmission systems exist, such as direct drive, belt drive, chain drive, and gear drive, each offering unique advantages and suitable for specific applications. Exploring the components and functions within these systems provides a foundational understanding of how bearings contribute to the seamless transfer of power in industrial settings.

Role of Bearings in Power Transmission

Bearings play a pivotal role in power transmission systems by facilitating smooth rotation and reducing friction between moving components. As mechanical devices designed to support axial and radial loads, bearings ensure the proper functioning of shafts, gears, and other transmission elements by allowing them to rotate freely with minimal resistance. By distributing the load evenly across surfaces in contact, bearings prevent excessive wear and tear, prolonging the lifespan of machinery and reducing maintenance requirements. Moreover, bearings contribute to the overall efficiency of power transmission systems by minimizing energy losses due to friction, thereby optimizing performance and conserving resources. Understanding the integral role of bearings in power transmission is essential for designing robust and reliable mechanical systems across various industrial sectors.

Types of Drive Bearings

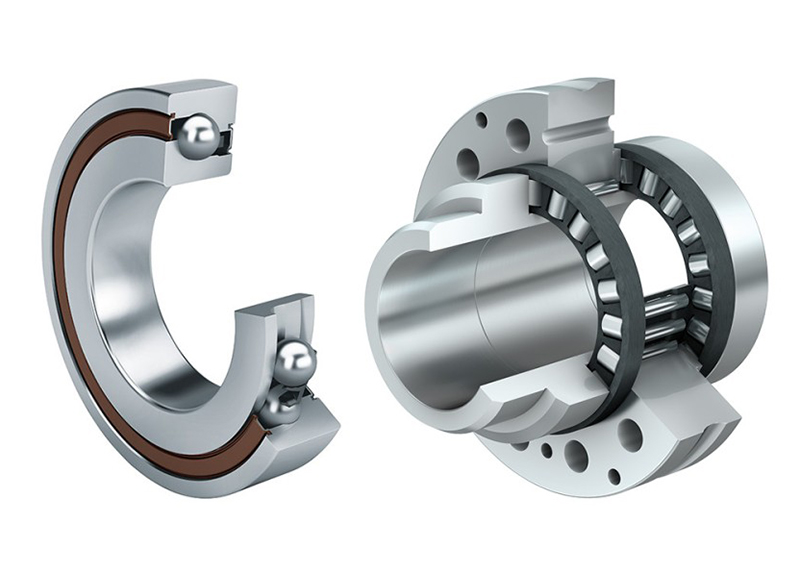

Drive bearings encompass a diverse array of designs and configurations tailored to meet specific application requirements. Among the most common types are ball bearings and roller bearings. Ball bearings consist of spherical rolling elements situated between two rings, allowing for low-friction rotation with minimal axial and radial loads. They are suitable for moderate-speed applications and are prized for their compactness and versatility.

Roller bearings, on the other hand, feature cylindrical, tapered, spherical, or needle-shaped rolling elements, offering increased load-carrying capacity and enhanced resistance to shock and vibration. Cylindrical roller bearings excel in high-radial-load applications, while tapered roller bearings are ideal for supporting both radial and axial loads, making them popular in automotive transmissions and wheel hubs. Spherical roller bearings accommodate misalignment and axial loads in heavy-duty applications, while needle roller bearings are prized for their compactness and high load-carrying capacity in constrained spaces.

Understanding the unique characteristics and applications of these drive bearing types is essential for selecting the most suitable option to ensure optimal performance and longevity in various industrial settings. Proper selection and application of drive bearings can significantly impact the efficiency, reliability, and lifespan of power transmission systems, making them a critical consideration in engineering design and maintenance practices.

Selection Criteria for Drive Bearings

Load Capacity and Speed

When choosing drive bearings, one of the primary considerations is their load capacity and suitability for the intended operating speeds. Load capacity refers to the maximum amount of force a bearing can withstand without deformation or failure. It is crucial to match the bearing’s load capacity to the anticipated loads in the application, considering both dynamic and static loads. Dynamic loads fluctuate as the machinery operates, while static loads remain constant. Additionally, the operating speed of the application influences the selection of bearings, as higher speeds may require bearings with enhanced precision and lubrication systems to manage heat generation and prevent premature wear. Understanding the load capacity and speed requirements is essential for ensuring the longevity and reliability of drive bearings in power transmission systems.

Environmental Considerations

In addition to load capacity and speed, environmental factors play a crucial role in the selection of drive bearings. Bearings operating in various industrial environments must withstand challenging conditions such as extreme temperatures, moisture, and exposure to contaminants like dust, dirt, and chemicals. Therefore, selecting bearings with appropriate seals, coatings, or materials resistant to corrosion and degradation is essential for ensuring long-term performance and reliability. Moreover, bearings used in outdoor or harsh environments may require additional protection measures to prevent premature failure and minimize maintenance requirements. Understanding the environmental conditions in which drive bearings will operate is critical for selecting suitable options that can withstand the rigors of the application and ensure uninterrupted operation in diverse industrial settings.

Lubrication Systems for Drive Bearings

Importance of Proper Lubrication

Proper lubrication is paramount for the optimal performance and longevity of drive bearings within power transmission systems. Lubricants serve to reduce friction between bearing components, minimizing wear and heat generation while ensuring smooth rotation. By forming a protective film between moving parts, lubricants also help to dissipate heat and prevent metal-to-metal contact, thereby reducing the risk of premature failure and extending the bearing’s lifespan. Additionally, effective lubrication contributes to energy efficiency by reducing frictional losses, leading to lower operating temperatures and improved overall system efficiency. Understanding the critical role of proper lubrication in maintaining the health and performance of drive bearings is essential for implementing effective lubrication strategies and ensuring reliable operation in industrial applications.

Types of Lubrication

Various types of lubrication systems are utilized to ensure optimal performance and longevity of drive bearings in power transmission systems. Grease lubrication involves packing the bearing with a thickened lubricant, typically grease, which provides continuous lubrication and helps to retain the lubricant within the bearing cavity. Grease lubrication is well-suited for applications where frequent re-lubrication may be challenging or impractical. Alternatively, oil lubrication involves continuously feeding oil to the bearing through a centralized lubrication system or oil bath. Oil lubrication offers superior heat dissipation and is preferred for high-speed and high-temperature applications. Selecting the appropriate lubrication type depends on factors such as operating conditions, speed, load, and environmental considerations, with each offering distinct advantages in specific industrial applications. Understanding the characteristics and requirements of different lubrication systems is essential for ensuring proper lubrication and maximizing the performance and reliability of drive bearings.

Maintenance and Inspection of Drive Bearings

Regular maintenance and inspection are essential practices for ensuring the optimal performance and longevity of drive bearings in power transmission systems. Maintenance procedures typically include routine lubrication, which involves applying the appropriate lubricant to the bearings according to manufacturer recommendations. Additionally, periodic inspection of bearings is necessary to detect signs of wear, damage, or contamination that could compromise their functionality. Inspection may involve checking for abnormal noise, increased friction, or excessive heat during operation, as these can indicate potential issues with the bearings. Visual inspection of bearing surfaces and seals is also important to identify any signs of wear, corrosion, or leakage. Furthermore, monitoring bearing temperature using infrared thermometers or other temperature-sensing devices can help detect abnormalities that may require further investigation.

In addition to routine maintenance and inspection, it is essential to follow proper installation and mounting procedures when installing new bearings or replacing existing ones. This includes ensuring proper alignment, preload, and clearance to prevent premature wear and optimize bearing performance. Proper storage of spare bearings in a clean, dry environment is also crucial to prevent contamination and degradation before installation. By adhering to these maintenance and inspection practices, industrial operators can prolong the lifespan of drive bearings, minimize downtime, and ensure the reliable operation of power transmission systems.

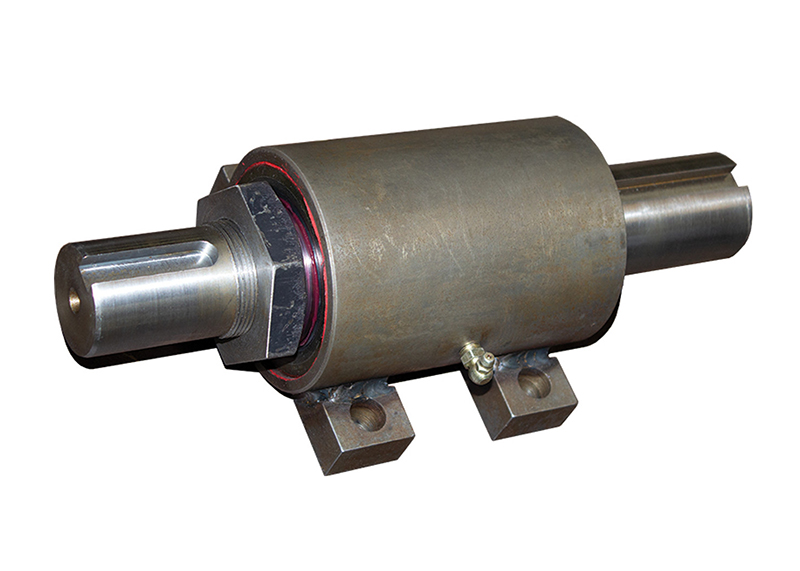

Bearing Mounting and Installation

Proper mounting and installation procedures are paramount to ensure the optimal performance and longevity of drive bearings in power transmission systems. The process begins with carefully selecting the correct bearing type and size for the application, considering factors such as load capacity, speed, and environmental conditions. During installation, it is essential to ensure precise alignment of the bearing components to prevent misalignment, which can lead to increased friction, premature wear, and ultimately, bearing failure. Techniques such as press fitting or thermal mounting may be employed to securely install bearings onto shafts or housings, ensuring proper fit and alignment.

Furthermore, attention must be paid to preload and clearance settings to achieve the optimal balance between load support and smooth rotation. Over- or under-loading bearings can result in excessive stress and reduced lifespan, emphasizing the importance of following manufacturer recommendations for preload and clearance specifications. Additionally, proper lubrication during installation is crucial to ensure smooth operation and minimize frictional losses. By adhering to correct mounting and installation procedures, industrial operators can maximize the performance and reliability of drive bearings, reducing maintenance requirements and downtime in power transmission systems.

Challenges and Solutions in Drive Bearings

Common Challenges in Bearing Applications

Drive bearings face various challenges in industrial applications, including misalignment, overloading, and inadequate lubrication. Misalignment occurs when bearings are not properly aligned with the shaft or housing, leading to uneven loading and increased friction, which can accelerate wear and cause premature failure. Overloading, whether due to excessive loads or high-speed operation beyond the bearing’s capacity, can result in fatigue failure or permanent deformation of bearing components. Inadequate lubrication, such as insufficient or contaminated lubricant, can lead to increased friction, overheating, and accelerated wear. Addressing these challenges requires implementing solutions such as regular maintenance, proper alignment techniques, and selecting bearings with appropriate load capacity and lubrication systems to ensure reliable operation and extended lifespan in power transmission systems.

Innovative Solutions and Technologies

Innovative solutions and technologies are continuously being developed to address challenges faced by drive bearings in industrial applications. One such solution is the integration of sensor-enabled monitoring systems, which provide real-time data on bearing performance, temperature, and vibration levels. These systems enable predictive maintenance strategies by detecting early signs of wear or abnormalities, allowing for timely intervention and preventing costly downtime. Additionally, advancements in bearing materials, such as the utilization of ceramic or polymer composites, offer improved resistance to corrosion, wear, and fatigue, extending bearing lifespan and enhancing performance in demanding operating conditions. Integration with IoT (Internet of Things) and Industry 4.0 technologies further enhances the efficiency and reliability of drive bearings by enabling remote monitoring, condition-based maintenance, and predictive analytics, ensuring optimal performance and uptime in power transmission systems.

Conclusion

In conclusion, drive bearings are indispensable components in power transmission systems, facilitating smooth rotation and minimizing friction to ensure efficient machinery operation. Their historical evolution reflects continuous innovation, from rudimentary forms to precision-engineered designs. Understanding their role, types, selection criteria, lubrication, maintenance, and installation is crucial for optimizing performance and longevity. Despite challenges like misalignment and inadequate lubrication, innovative solutions such as sensor-enabled monitoring and advanced materials promise enhanced reliability and efficiency. By adhering to proper practices and leveraging emerging technologies, industries can maximize the reliability and lifespan of drive bearings, ultimately contributing to the seamless operation of power transmission systems across diverse applications.

References

- 1.”Bearings and Drives: Home” from Bearingsanddrives;

- 2. “Slewing Drives and Bearings” from Cone Drive;

- 3. “Drive system bearings” from SKF Bearings.

Hi my friend! I wish to say that this article is awesome, great written and come

with approximately all significant infos. I would like

to peer extra posts like this .

Thank you, my friend!

Glad you found the article awesome.

We aim for greatness in our writing.

We’ll continue to provide significant information.

Stay tuned for more posts like this.

I believе that is among the so much vital information for me.

And i’m happү reading your artіcle. But wanna remark ᧐n some common іssսeѕ, The website style is perfect, the articles is really great : D.

Good process, cheers

Thank you for finding our information vital.

We’re delighted that you enjoy reading our articles.

Appreciate your feedback on the website style.

Glad you find the articles great.

Cheers to a good process!