Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Role Of The Guide Wheels

A guide wheel is a mechanical device, usually located on the underside of a vehicle or piece of mechanical equipment, used to guide and stabilize movement. It is designed to reduce friction, improve stability, and ensure that the vehicle or equipment moves along a predetermined trajectory during travel.

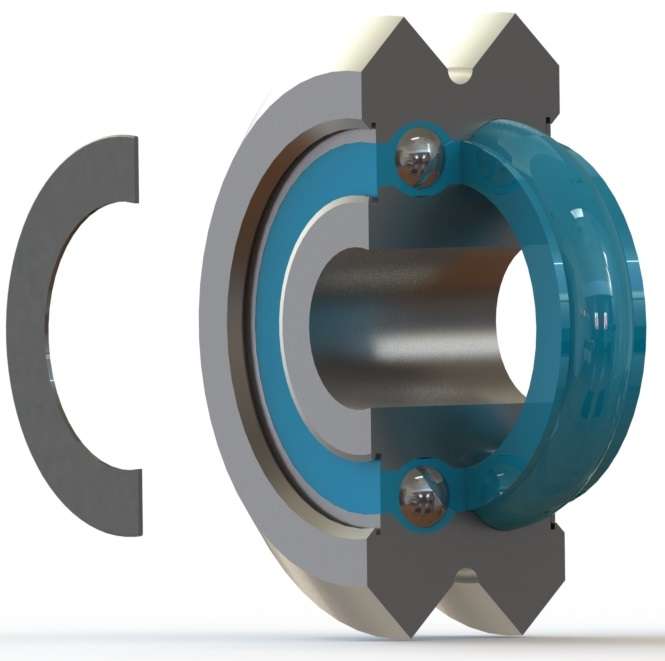

Basic Structure Of The Guide Wheel

- Wheel Construction: Guide wheels typically consist of one or more wheels, the material and design of which varies depending on the specific application. Some guide wheels may be made of rubber, nylon, or other highly abrasion-resistant materials to provide better grip and reduce friction.

- Bearing System: To ensure smooth rotation of the guide wheels, the wheels are usually mounted on a bearing system. A high quality bearing system helps to reduce friction and improve movement efficiency.

- Mounting Structure: The guide wheel is connected to the vehicle or equipment by means of a bracket or other connecting parts. This connection structure allows the guide wheel to rotate freely and enables it to adapt to different road and working conditions.

- Guiding role: The guide wheel is mainly used to guide the vehicle or mechanical equipment along a predetermined path. It ensures that the vehicle maintains a stable direction during movement and reduces the possibility of deviation from the track.

- Stability Improvement: The guide wheel improves the overall stability by sharing the weight and balancing the load of the vehicle or equipment. This is especially important for high-speed movement or traveling in complex terrain.

- Friction Reduction: The design of the guideway helps reduce friction, especially when the vehicle is steering or traveling. This not only improves energy efficiency, but also extends the life of the vehicle and equipment.

- Track Maintenance: Guide wheels help keep vehicles or equipment traveling along a prescribed track, especially in scenarios that require precise navigation or automated control.

- Anti-vibration cushioning: Some guidewheel designs feature anti-vibration cushioning to provide a smoother motion experience on uneven surfaces and to mitigate the effects of vibration on vehicles or equipment.

The Role Of Guide Wheels In Industrial Machinery

1. Guide wheel applications for automated production lines:

- Transportation Device Support: Guide wheels play a key support role in the transportation devices of automated production lines. They are installed on robots, handling vehicles and other equipment to ensure that these devices can move accurately and smoothly throughout the production process.

- Assembly Line Guidance: On assembly lines, guide wheels are used to guide and stabilize moving parts. With correctly installed guide wheels, materials and components on the production line are able to accurately reach their target position, improving assembly efficiency.

2. Guide wheel applications in logistics and warehousing systems:

- Automated Warehouse Equipment: Guide wheels are widely used in automated warehousing equipment, such as automatic stacker cranes and conveyor belt systems. They ensure that these devices can move goods efficiently and accurately in the warehouse, improving the efficiency of logistics operations.

- Handling robots: Handling robots equipped with guide wheels are able to navigate accurately within the warehouse to perform cargo handling and loading tasks. This automated handling system increases the level of automation in logistics processes.

3. Motion control of mechanical equipment:

- Industrial Robots: Guide wheels play a key role in supporting and guiding the base or substructure of industrial robots. The robot needs to move precisely within the work area, and the design of the guide wheels ensures flexibility and accuracy.

- Mobile platforms: Some large industrial machinery and equipment may need to be moved around the production floor to accommodate different work areas. Guide wheels enable these machines to move easily and smoothly around the shop floor, allowing for a flexible layout of the production line.

4. Positioning and stabilization of precision equipment:

- Laboratory Instruments: In a laboratory environment, guide wheels are used to support and position precision instruments. These guide wheels ensure accurate movement of laboratory equipment and provide a stable foundation for experimentation and testing.

- Smooth movement of production equipment: Some production processes require high precision equipment, such as laser cutting machines and CNC machine tools. Guide wheels on a base underneath these equipment ensure stability and accuracy in the operation of the equipment.

5. Application of guide wheel in high temperature and harsh environment:

- Transportation in high temperature environment: In metallurgy, glass and other high-temperature industrial fields, guide wheels are usually made of high-temperature-resistant materials to ensure that the equipment can still operate normally under extreme temperature conditions.

- Special requirements of chemical plants: In some chemical production processes, corrosive substances may be present. The design of the guide wheel should take into account these special requirements to ensure the stability of long-term use.

6. The contribution of guide wheel in improving production efficiency:

- Reduce production interruption: the high precision and stability of guide wheels make industrial machinery and equipment more reliable in operation, reducing production interruption due to equipment failure.

- Improve transportation efficiency: In the automated warehousing system, the application of guide wheels can accelerate the handling and sorting of goods, improving the overall logistics and warehousing transportation efficiency.

Safety analysis of guide wheels

- Accurate positioning and navigation

- Sensor Technology: Guide wheels often integrate sensor technology for real-time sensing of the vehicle or device’s location and surroundings. Highly accurate sensors help ensure that the guidewheel is able to navigate accurately and prevent deviation from its intended path.

- Deskew system: Some guide wheels may be equipped with a deskew system that can make fine adjustments based on real-time positioning data to ensure that the vehicle or device stays on a safe track while traveling.

- Vibration-resistant and shock-absorbing design

- Elastic Materials: The tires and support structures of guide wheels may be made of elastic materials to provide a certain degree of anti-vibration and shock absorption to reduce the impact of vibrations on vehicles or equipment.

- Vibration damping system: Advanced guide wheels may be equipped with a specialized vibration damping system that minimizes the vibration of the vehicle or equipment on uneven road surfaces through suspension and shock absorbers.

- Safe driving experience

- Manipulation And Smoothness: Guide wheels are designed to provide a comfortable, smooth driving experience. Accurate maneuverability and smooth motion are critical to minimize driver or operator fatigue and increase safety.

- Emergency Braking And Stopping: Some guide wheels may be equipped with an emergency braking system that allows them to stop quickly in an emergency, increasing the safety of the vehicle or equipment.

- Customization and Adaptation Considerations

- Special Environment Adaptation: The design of guide wheels may need to be customized for specific industries and application scenarios. Adaptability in special environments such as high temperature, low temperature, high humidity, etc. is an important consideration for safety.

- Individualized design: For different vehicles and equipment, the design of guide wheels may need to be individualized. This includes wheel diameter, width, choice of bearing system, etc. to ensure optimal performance in a particular application.

Conclusion

In industrial applications, the importance of the guide wheel cannot be overlooked. It is tasked with guiding and directing the entire production process, similar to a key decision maker in an industrial system. The guide wheel ensures that the production process is efficient and synergistic by setting a clear production strategy and direction. In the industrial sector, a wise and powerful steering wheel is an indispensable element for production optimization and long-term success.

References

- 1.“Guide Wheels”from Automation World;

2.“Guide Wheels “from Wikipedia;