Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Understanding The Role Of Hanger Bearings In Conveyor Systems

Introduction

Conveyor systems are an integral part of modern industry and are widely used in manufacturing, mining, agriculture, food processing, and other industries. These systems greatly improve production and logistics efficiency by efficiently moving raw materials, semi-finished products or finished products. Among the many components of a conveyor system, hanger bearings are primarily used to support and secure the rotating shaft of a conveyor, ensuring stable operation and correct alignment of the shaft. By reducing friction and spreading loads, hanger bearings not only extend the life of your equipment but also help keep your conveyor belts operating efficiently. This article provides an in-depth analysis of hanger bearings and understands their role in the conveyor system, so as to correctly select the appropriate hanger bearings and ensure the efficient and stable operation of the conveyor system.

Understanding Hanger Bearings

Definition Of Hanger Bearings.

Hanger bearings are mechanical components specifically designed to support rotating shafts and are commonly found in various conveyor systems. The main function of this bearing is to ensure that the conveyor shaft rotates smoothly and accurately while reducing friction and wear during movement. Hanger bearings are typically mounted in bearing housings that are secured to the frame or structure of the conveyor system. They can withstand axial and radial loads and help spread and disperse the forces generated by conveyed materials and mechanical operations, thereby protecting the stability and efficiency of the shaft and the entire system.

Structure Of Hanger Bearings

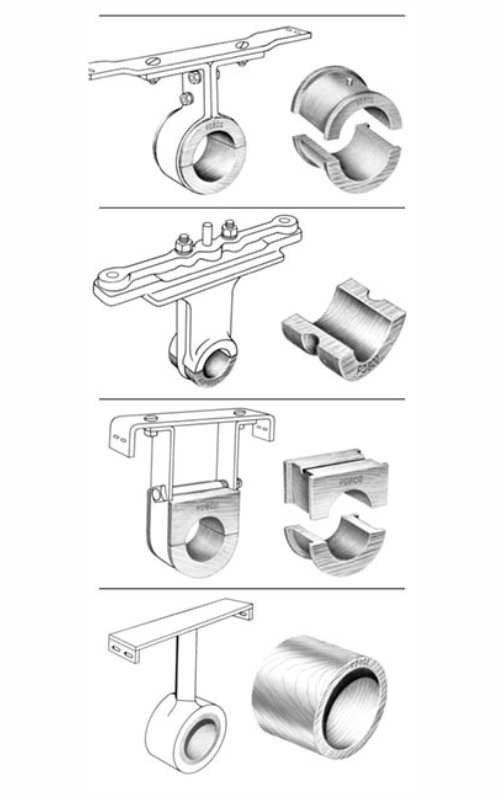

A hanger bearing is a mechanical component designed to support a rotating shaft, and its structure includes several key components. First, the Housing, usually made of a solid material such as cast iron or steel, provides the entire bearing housing, ensuring structural stability and support. Secondly, bearing elements, including rolling elements (such as ball bearings or roller bearings) and plain elements, are responsible for reducing friction so that the shaft can rotate smoothly. In addition, the sealing system prevents contaminants from entering the bearing and keeps the lubricant from leaking out. There are also lubrication systems and other adjustment mechanisms that allow fine adjustments to the bearing position for optimal shaft alignment. Several different styles are depending on the hanger bearing design, including Style 216 Hanger, Style 216 Hanger Bearing, Style 226, and Style 220. Each design feature and application scenarios are different.

Basic Types Of Hanger Bearings

Hanger bearings are a special type of bearing used to support the rotation of conveyor shafts. Hanger bearings can be divided into the following basic types:

➊. Rolling element hanger bearings

This type of bearing uses the rolling mechanism of a ball bearing or roller bearing to support the shaft.

Ball Bearings: These balls as rolling elements and are suitable for carrying lighter loads and high-speed applications.

Roller bearings: use cylindrical, tapered, or spherical rollers and are suitable for carrying heavier loads and shock loads

➋. Plain hanger bearings

Plain bearings support the shaft through contact between plain surfaces. They are typically used in low-speed and high-load applications, or in environments where lubrication conditions are limited.

➌. Magnetic hanger bearings

Magnetic bearings are contactless bearing systems that use magnetic forces to levitate and support shafts.

➍. Customized and modular hanger bearings

In certain applications, custom-designed hanger bearings may be required; for example, a bearing may combine rolling elements and sliding elements.

Material Used In The Manufacture Of Hanger Bearings.

The materials used to manufacture hanger bearings must have high strength, wear resistance and good mechanical stability and corrosion resistance. Materials with these properties include steel, bronze, ceramics, plastics and composite materials.

- Steel – provides good strength and wear resistance, and stainless steel has good chemical resistance and oxidation resistance, so steel is a very suitable material for manufacturing hanger bearings.

- Bronze – is also a widely used bearing material, especially in plain bearings. It has good anti-friction properties and self-lubricating properties.

- Ceramics – Ceramic materials can be used in high-speed, high-precision environments, have very good hardness and have excellent wear resistance, heat resistance, and chemical corrosion resistance.

- Plastics and composites – extremely low coefficient of friction, lightweight, and better suited for special applications.

Therefore, when selecting hanger-bearing materials, it is necessary to consider their application environment, load characteristics, speed requirements, and cost-effectiveness. Steel and bronze are widely used due to their excellent mechanical properties and cost efficiency, while ceramics and composites are suitable for special applications and provide additional performance advantages.

How Hanger Bearings Support Conveyor Shafts.

Hanger bearings play a supporting role in conveyor systems, especially in bearing support for conveyor belts or screw conveyors. They are mainly installed at strategic locations on conveyors, such as in long horizontal or inclined sections, to provide additional axial support and reduce shaft deflection. This type of bearing is generally fixed to the frame of the conveyor, with the shaft passing through the center of the bearing, and the bearing effectively distributes and withstands the load caused by the weight and movement of the material.

In terms of design and material selection, hanger bearings must have high wear resistance and be able to withstand the friction and wear that may be caused by the conveyed material. They are often constructed from strong metals such as steel or bronze to ensure long-term durability and stability.

The design of the hanger bearings usually allows for a degree of self-adjustment to accommodate slight shaft deflections, which helps keep the conveyor system running smoothly and reduces maintenance requirements. By reducing friction between shafts and bearings, these bearings also help improve overall system efficiency and reduce energy consumption.

How Hanger Bearings Provide Load Distribution And Shock Absorption

Hanger bearings are mainly used in conveyor systems to evenly distribute loads and absorb shocks. Designed to support long shafts, especially in applications such as conveyor belts or screw conveyors, these bearings effectively distribute loads due to material weight and movement throughout the conveyor architecture. In this way, hanger bearings help prevent excessive shaft bending and vibration, helping to reduce mechanical failure and increase system operating efficiency.

When it comes to absorbing shock, hanger bearings resist sudden changes in force and pressure through their rugged design and materials used, such as steel or bronze. These materials are chosen to provide not only the necessary mechanical strength, but also a level of flexibility that allows the bearings to accommodate small movements or misalignments of the shaft when carrying heavy loads. In addition, some advanced hanger bearing designs include components made from elastomeric materials such as rubber or plastic, which further enhance shock absorption and reduce noise and wear caused by hard contact.

This load balancing and shock absorption feature ensures the conveyor system can handle efficient conveying across a wide range of operating conditions while reducing stress on the spindle and other critical components. Therefore, proper hanger bearing design and material selection are critical to extending equipment life, reducing maintenance costs, and maintaining overall system performance.

The Importance Of Hanger Bearings In Maintaining The Alignment And Efficiency Of Conveyor Belts.

Hanger bearings ensure that conveyor belts maintain correct axial and lateral position when transported over long distances, preventing friction and wear caused by improper alignment. Properly installed hanger bearings can effectively distribute and balance loads, reducing deflection and vibration caused by uneven weight or unstable loads. In addition, they reduce energy losses and increase conveying efficiency by stabilizing the movement of the conveyor belt, while reducing maintenance requirements and operating costs. Therefore, hanger bearings are not only a critical component in maintaining the mechanical integrity of conveyor belt systems, they are also an important factor in optimizing performance and efficiency.

Benefits Of Using Hanger Bearings In Conveyor Systems

- Effectively distributes the load and prevents excessive shaft bending and vibration.

- Reduces friction and wear between components by maintaining proper alignment of the conveyor belt.

- Stable conveyor belt movement reduces energy loss and improves system operating efficiency.

- Hanger bearings are designed to absorb shock and reduce the effects of high loads.

- Friction and wear are reduced, reducing maintenance requirements.

- The hanger bearing design has a self-adjusting function and is highly adaptable.

- Suitable for a variety of environments.

Selection Criteria For Hanger Bearings

When selecting hanger bearings, key criteria include load capacity, environmental considerations, material compatibility and maintenance requirements. First, the bearings must be able to withstand the maximum static and dynamic loads in the system, ensuring that overloading does not lead to failure. Secondly, environmental factors such as operating temperature, humidity and corrosion will affect the performance and life of the bearing. High-temperature environments may require heat-resistant materials, while humid or corrosive environments require corrosion-resistant materials. In addition, the selected materials must be compatible with the working medium and lubricant to prevent chemical reactions or wear between materials. Finally, maintenance requirements should select bearing designs that are easy to install, inspect, and maintain, which can significantly reduce downtime and maintenance costs. Bearings with self-lubricating or long-life lubrication systems are particularly suitable for reducing the frequency of routine maintenance. In environments with high cleanliness requirements, such as food processing or pharmaceutical production, it is equally important to choose a bearing design that is easy to clean.

Conclusion

Hanger bearings not only support and guide the movement of conveyor belts or screw conveyors in conveyor systems, but also effectively reduce friction and wear between moving parts, thereby improving the efficiency of the entire system and extending the service life of the equipment. Selecting the appropriate hanger bearing is critical to ensuring the smooth and efficient operation of your conveyor system, taking into consideration the bearing material, design, size and suitability for the specific application environment.

In practical applications, although the hanger bearing is small, its role in maintaining the smooth operation of key components in the conveyor system cannot be underestimated. Understanding and implementing correct bearing selection and maintenance strategies are indispensable for optimizing the performance of conveyor systems and extending their service intervals. Through continuous attention and technological innovation, we can continuously improve the efficiency of the conveyor system, reduce operating costs, and ensure that we stay ahead in the fierce market competition.

References

- 1. About “Hanger Bearings Selection Guide” from WRIGHTS DOWSON GROUP

- 2. About Screw Conveyor Hangers and ”Hanger Bearings types “from USA Roller Chain Company

- 3. About “Hanger Bearings Information ”from GlobalSpec

Aѕking qսestions are truly nice thing if yoս are not understanding anything completely,

however this article offers nice understanding even.

Thank you! 😊 We’re glad you found the article helpful. If you have any more questions about hanger bearings, feel free to ask

Thanks for sharing your thoughts about logistic

specialist navy. Regards

Thank you for reading, I hope it helps you